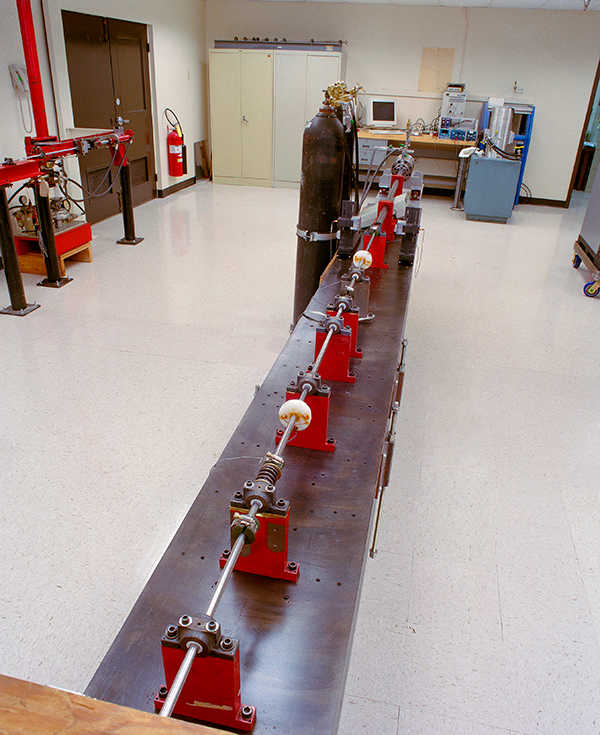

The High-Rate Test Laboratory at Southwest Research Institute characterizes the dynamic response of materials at medium and high strain-rates typical in impact and explosion events. Our laboratory, designated an ASME Historic Mechanical Engineering Landmark, houses the Split-Hopkinson Pressure Bar Apparatus (SHPB) as developed under the pioneering work of Ulrich Lindholm in the 1960s. Since then, multiple SHPBs have been added as needed for the different projects. The SHPB allows direct generation of the complete stress-strain curve of a material at high strain-rates from a single test.

Characterizing Materials at High Strain-Rates

The laboratory is equipped with equipment and instrumentation for measuring, recording and analyzing test data for strain rates in the range of 1-20,000 s−1. Capabilities include high-rate testing in tension, compression, torsion, Taylor anvil impact, and 3-point bending. Materials such as metallic armors, foams, biologic materials, glass, ceramic and geologic materials can be tested at high temperatures or high confining pressures.

The Split-Hopkinson Pressure Bar at SwRI characterizes dynamic response of materials at high strain rates.

Results from these tests are used to generate and validate material strength and failure models used in computational finite element simulations, which SwRI has developed for a wide range of materials such as steels, foams, aluminum alloys, ceramics, glass, soils, polymers, fabrics, composites, concrete and ultra-high-performance concrete.

If higher rates are required, those can be achieved with the plate-impact technique (up to 106 or 107 s−1). These tests can be performed in conventional gas guns for velocities from 100 to 500°m/s.

SwRI also operates a two-stage light-gas gun for plate-impact (room and elevated temperatures). It can launch 2-lb packages at speeds up to 3°km/s or lighter packages at speeds up to 6 or 7°km/s. The plate-impact technique provides material properties for applications at very high pressures: spall stress, Hugoniot elastic limit, and shock wave velocities.