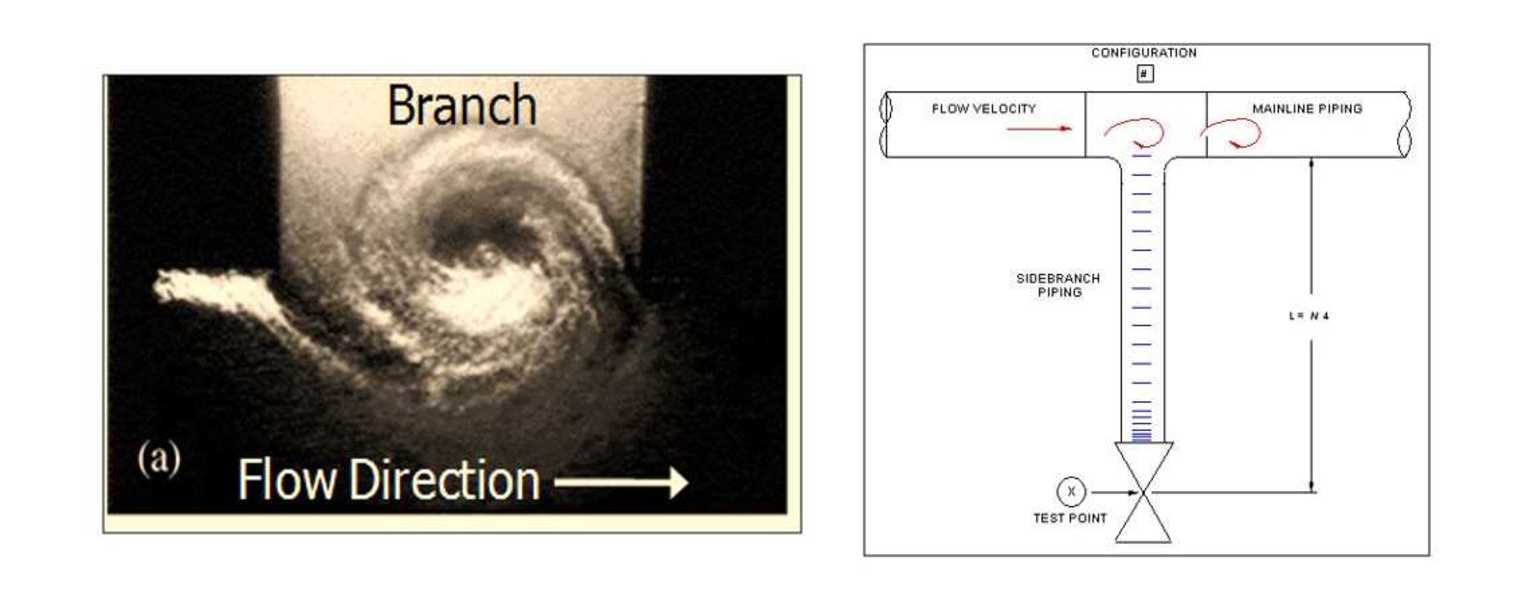

Vortex-shedding of fluid flow past a change in geometry (dead leg stub, thermowell, etc.) can excite acoustic natural frequencies in the system, which create high pulsations and vibration problems. Adding a flow-induced, vortex-shedding (FIV) analysis in the design stage can predict pulsation problems that may occur and recommendations can then be developed to avoid them.

- Piping systems with high flow require a pulsation analysis

- Applies to centrifugal compressor stations, metering areas, PSV headers, and piping hubs

- Most common source of low frequency pulsations in centrifugal compressor station

- Advanced techniques for FIV analyses validated through laboratory and field testing

Field testing facility at SwRI

Field testing facility at SwRI

To contract with SwRI, please contact the Machinery Services Hotline at +1 210 522 3000.

For more information, contact Sarah B. Simons or call +1 210 522 2418.