Failure investigations help clients prevent failures, extend component service life, and establish inspection intervals. SwRI conducts analyses to:

- Determine the causes of failure

- Identify design and operating deficiencies

- Improve reliability and safety

- Lower operating costs

- Provide impartial evaluations

Primary Failure Analysis

SwRI engineers have extensive experience in identifying failure mechanisms including:

- High- and low-cycle fatigue

- Stress corrosion cracking

- High-temperature degradation

- Brittle failure mechanisms

- Fretting and wear mechanisms

- Welding defects

- Petrochemical corrosion mechanisms

Failure Prevention Facilities & Equipment

Visit Metallurgical Analysis Laboratory to learn more about our equipment and services, including:

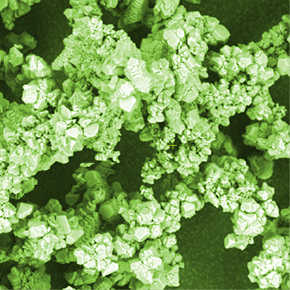

- Three scanning electron microscope (SEM) systems for fractographic and metallographic analysis

- Servo-hydraulic loading stage for SEM to enable in situ analysis of controlled fractures under high magnifications

- Powder X-ray diffractometer for crystallographic analysis of materials and deposit analysis

- Two profilometers for surface roughness measurements

- Three energy-dispersive X-ray spectrometer (EDS) systems, coupled to each SEM, to identify elemental composition of materials, such as aggressive corrosion products

- Scanning auger microprobe spectrometer to identify elemental composition of contaminants and microstructural phases

- Scanning-tunneling and atomic force microscopes (STM/AFM) for analysis of nanoscale surface topography

- Metallographs for heat treat verification, microstructural examination, and material characterization

- Portable microscope, hardness testing unit, and replication kit for field investigations

- Fully equipped mechanical testing laboratory, including 40 closed-loop, servo-hydraulically controlled mechanical test systems

- Autoclaves for high-pressure and high-temperature corrosion investigations

- Fourier transform infrared (FTIR) spectrophotometer for molecular-level compositional analysis of non-metallics

- Raman spectroscopic imaging and microanalysis system for spatially mapped compositional analysis of various materials

- HEPA filtrated metals lab and hot cells capable of handling multicurie specimens

Powerful Scanning Electron Microscope

SwRI’s SEM features energy dispersive X-ray spectrometer to localize analysis and produce clear, sharp images of objects magnified over 1,000,000 times.

LEARN MOREAdditional Failure Analysis Services

When investigations require in-depth studies of failure mechanisms, SwRI applies:

- Finite element analysis

- Damage tolerance analysis

- Life extension predictions

- Mechanical testing

- In-service condition assessment

- Nondestructive evaluation

- Maintenance optimization

- Design or redesign