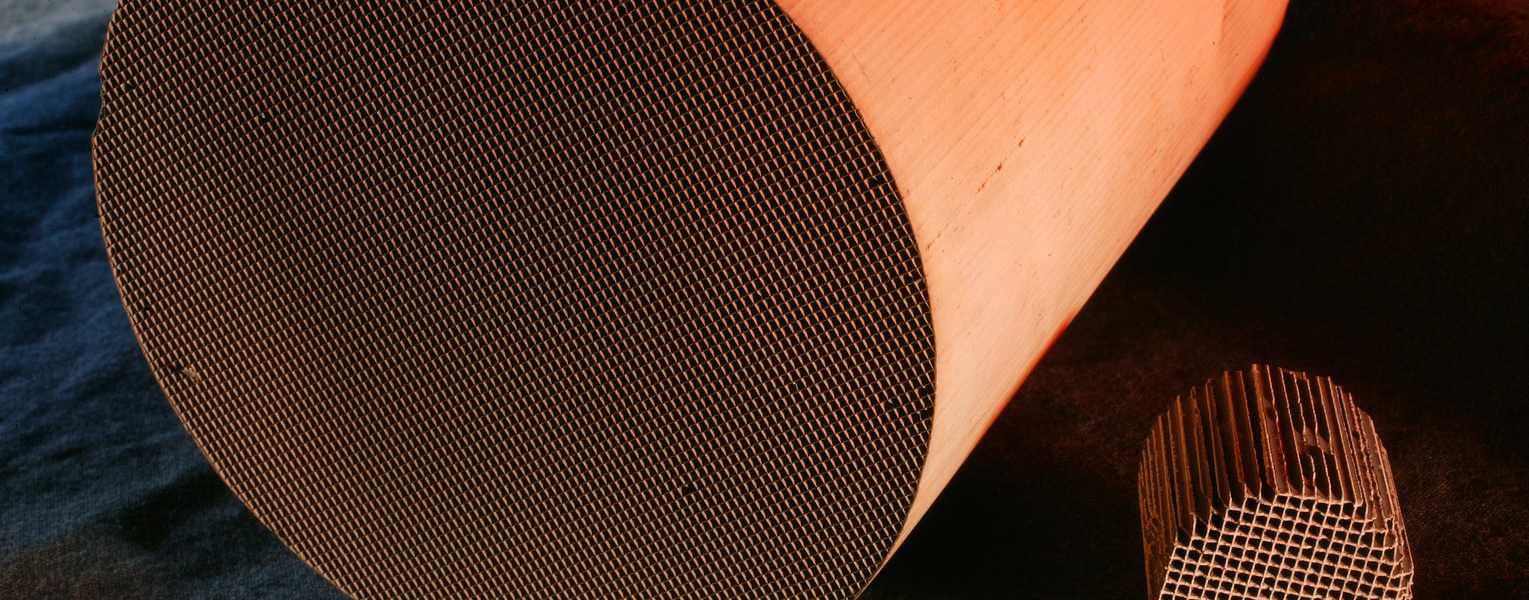

Southwest Research Institute (SwRI) has an advanced catalyst testing laboratory for catalyst analysis and evaluation to support client-directed testing. SwRI offers catalyst characterization and post-mortem analysis to evaluate Aftertreatment System Technologies under realistic conditions. In our state-of-the-art Universal Synthetic Gas Reactor (USGR), catalyst core samples are preconditioned and then run through specialized tests with specific gas mixtures, temperatures, and time durations to fit our client’s desired application.

Catalyst Characterization & Testing

Catalyst characterization tests include steady-state performance, perturbated performance, temperature ramps and stepped light-off tests, and thermal and chemical aging.

Post-mortem catalyst analysis techniques compliment these tests to provide a complete picture of physical changes to catalyst structure as well as catalyst poisoning. These techniques include:

- Elemental composition analysis.

- Scanning electron microscopy (SEM)

- Optical microscopy

- X-ray diffraction (XRD) to identify crystalline structures and platinum group metals (PGM) particle size

- Brunauer, Emmett and Teller (BET) surface area measurements

- Additional tests available based on client specifications

Clients can provide a range of gas compositions the aftertreatment system is likely to be exposed to during operation. SwRI’s catalyst analysis and aftertreatment R&D team will design a series of experiments with the client to either characterize the current system performance or to identify optimal exhaust gas composition for the aftertreatment system.

The USGR system is ideal for conducting efficient kinetic modeling on new catalyst formulations to determine whether they can be incorporated into the aftertreatment system and the effects of catalyst poisoning on their performance.

SwRI’s catalyst testing laboratory includes the USGR for bench-scale testing, the Exhaust Composition Transient Operation Lab (ECTO-Lab) for full-size aftertreatment system component testing using a burner system to simulate engine exhaust. Additionally, aftertreatment systems can be tested with an actual engine setup in our engine test cells.

R&D 100 Award for Catalyzed Diesel Exhaust Fluid

Cat-DEF™ system that improves NOX and CO2 emissions for diesel engines recognized by R&D World as one of the 100 most significant innovations of 2021.

Learn MoreRelated Services

- AC2AT-II Join Industry Consortium

- Catalyst Aging Services

- Custom Aftertreatment Test Stands

- Catalyst Formulation

- Emissions

For more information, contact Scott Eakle or call +1 210 522 5095.