Hypersonic flight conditions require materials to survive extreme conditions. The accurate characterization, constitutive model development and dynamic/ballistic performance of advanced composite and thermal protection system materials are critical to the development of hypersonic systems. SwRI specializes in material characterization and ballistic testing. This allows SwRI to develop material models for next-generation composites and high-temperature alloys.

SwRI has a range of test equipment that may be used to measure the strength, cumulative damage and failure of composite, metallic and ceramic materials under different dynamic loading conditions and temperatures. SwRI has a large suite of facilities, including high-rate compression and Split-Hopkinson Pressure Bar & Plate Impacting Testing, compression, torsion systems. Multiple high-temperature ovens are available for heating materials up to 1800 °C (3270 °F). Testing at temperature of 2200 °C (4000 °F) and beyond is also available for select tests.

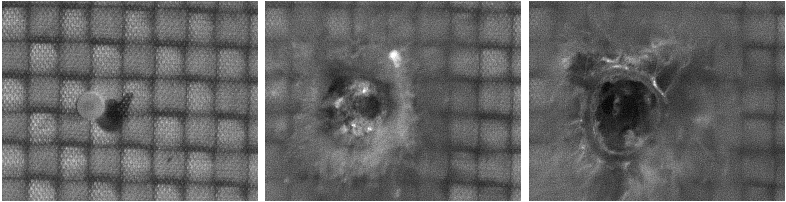

In addition, SwRI has a comprehensive array of impact testing facilities that may be used to test the ballistic performance of materials. Flyer plate impact tests can be used to measure equation of state parameters for a variety of materials. Ballistic impact tests of rain and weather simulants against thermal protection systems may be tested under a variety of atmospheric and flight conditions. Pre- and post-test materials may be internally visualized by state-of-the-art industrial CT scanning.

High-speed images of a nylon sphere impacting a composite material at hypersonic velocities

Related Services

- Hypersonic Research

- Hypersonic Aerothermodynamics

- Hypersonic Flight Test

- Split-Hopkinson Pressure Bar & Plate Impact Testing

- Ultra-High Temperature Materials Characterization

- Blast & Impact

- Measurement of Ballistic & Explosive Events

- High-Speed Data Acquisition

- Dynamic Materials Characterization

- Nondestructive Evaluation

Or call Sidney Chocron at +1 210 522 3698.