The energy density of lithium-ion batteries has made them popular and reliable for applications in consumer products and electric vehicles. While they are powerful and efficient, lithium-ion batteries can also pose fire safety risks. Testing battery cells, packs and modules helps to identify risks under certain conditions. Mechanical battery testing is crucial in evaluating materials, parts and components to understand how environmental conditions or mechanical forces affect battery performance, safety and efficiency.

Laboratory Facilities & Certification

Southwest Research Institute performs multiple battery tests for a variety of applications using various analytical, electrical and mechanical methods. Our mechanical engineers collaborate with automotive engineers, materials scientists and electrical engineers to develop testing and research services. Our Mechanical & Environmental Battery Testing Laboratory is certified under an ISO 9001:2015 Quality Management System and maintains an ISO 17025 accreditation for testing laboratories. The test lab personnel are specially trained to conduct component qualification and testing for the U.S. Department of Defense and NASA.

Environmental Battery Test Chambers

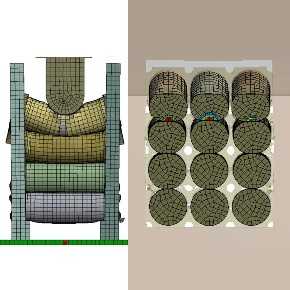

A nail-penetration test for mechanical battery testing at SwRI.

Mechanical battery testing is performed through SwRI’s Structural Engineering Department, which oversees several environmental battery test chambers and test facilities, including:

- Temperature and humidity

- Thermal heat dissipation

- Altitude

- Transportation vibration and shock

- Earthquake and office vibration

- Installation/handling shock, drop, crash hazard shock

- Wind and rain

- Ingress protection

- Corrosive atmosphere

- Acoustic noise

- Airborne contaminants

- UV and solar load

EV Battery Testing Services

SwRI performs a variety of standard and custom mechanical battery tests, including:

- SAE J2464 Testing for Rechargeable Energy Storage Systems

- UL 2580 Standard Battery Testing

- UL 9540A Testing for Battery Energy Storage Systems

- UN 38.3 Transportation Testing for Lithium-Ion Batteries

Battery Analysis for Mechanical Abuse

Learn how CAE models are helping analyze lithium-ion batteries, predicting internal short circuit, thermal runaway and fire propagation at cell, module and pack level.

Access WebinarRelated Services

- Product Assurance

- Physical Environmental Testing & Evaluation

- Battery Safety & Abuse Testing

- Battery Testing & Research