About the Header

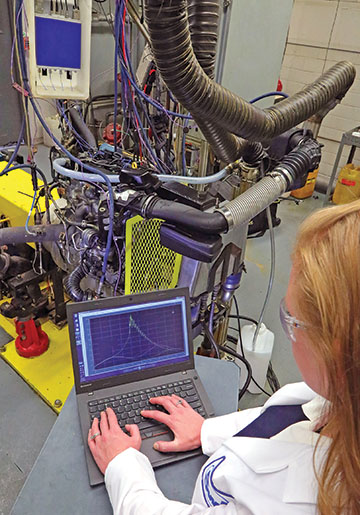

SwRI’s powertrain testing laboratory, the world’s first lab qualified to evaluate greenhouse gases from hybrid-electric trucks, installed new dynamometers optimized for all-wheel drive and electric-powered trucks to better evaluate fuel economy and emissions.

Southwest Research Institute is involved in nearly every facet of automotive and transportation research, from powertrains to fuels and lubricants to intelligent highways, connected and automated vehicles, and hypersonic flight. We continue to invest in research to reduce greenhouse emissions and improve vehicle efficiency, including newer efforts in electrification and connected vehicle systems. We also research power systems, emissions and fluids for heavy-duty, locomotive, marine and aircraft engines.

Automotive

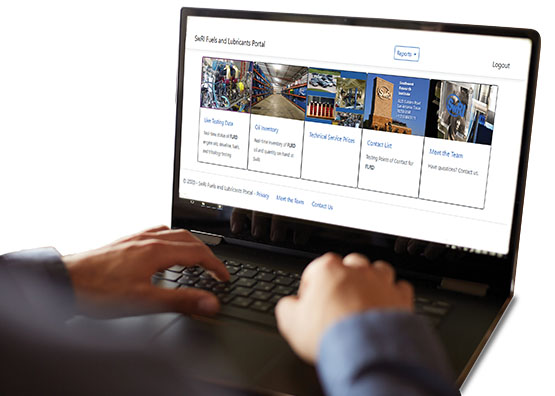

For more than 70 years, SwRI has evaluated transportation functional fluids to meet certification standards. In 2020, we launched an online portal to provide our clients with increased access to information on the tests that we conduct for them. The portal enhances interactions with our clients and makes it easier for them to do business with us, offering a real-time snapshot of the hundreds of tests being run in SwRI labs. The improved client access to information was particularly useful during pandemic operations. For instance, SwRI clients could track the first rounds of testing to the new GF-6 lubricant specification completed this year. Motor oils that meet this specification will improve fuel economy while offering better protection for today’s engines.

Meanwhile, we are investigating next-generation engine oils to understand how they can improve vehicle efficiency for proposed new standards. Currently, diesel engine oil specifications lack a standard test to measure lubricant-based efficiency, an area of particular importance to trucking companies, additive producers and oil marketers. If changing out the oil could improve vehicle efficiency by 1%, that could translate to millions of dollars in savings for fleet operators. SwRI has developed a variety of lubricant-targeted efficiency bench tests that stringently control a variety of parameters while discriminating as little as a 0.1% efficiency difference between oils. As regulatory bodies around the world continue to tighten engine emission requirements, the market for precision efficiency testing for diesel engine oils will continue to grow.

SwRI played a significant role in the development of the recently approved GF-6 lubricant specification, which certifies oils that will improve fuel economy while offering better protection for today’s engines.

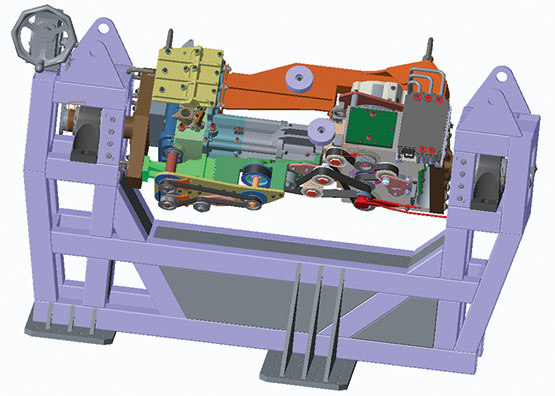

Engineers modified SwRI’s bearing test rig to extend hybrid-electric testing technology from light-duty vehicles to heavy-duty trucks. The instrumentation precisely measures oil film thickness on the connecting rod bearings of heavy-duty engines.

SwRI developed this sophisticated open inverter, which runs any electric motor to OEM specifications without OEM support and can evaluate client parts or fluids for electrified powertrains on various hardware.

SwRI is home to a lab dedicated to tribology, the study of interacting surfaces in relative motion, which focuses on friction, wear and lubrication, particularly in automotive applications. We have developed faster, lower-cost tribology bench tests to screen lubricant products before proceeding to more expensive and lengthier engine-based qualification tests. This prescreening allows our clients to evaluate many more products with the same budget.

In the emissions arena, we expanded the capacity of our Exhaust Composition Transient Operation Laboratory — the ECTO-Lab™ facility — adding new lean-burn transient and stoichiometric test stands. These computer-controlled, multi-fuel burner systems simulate engine exhaust conditions to rapidly age a range of emission control systems and conduct steady-state and transient evaluations. We also expanded the capacity and capability of our Universal Synthetic Gas Reactor technology, which simulates real-world exhaust gas conditions to quickly and accurately characterize catalyst performance. Expanding catalyst testing capacity allows simultaneous testing, improves turnaround time and reduces costs.

One of SwRI’s strengths is taking technology developed for one industry and creating new applications in another. For example, we are adapting supercritical CO2 power cycle technology developed for the electric power generation industry for use with internal combustion engines to recycle waste heat and reduce transportation-related CO2 emissions.

For an Oak Ridge National Laboratory and the U.S. Department of Energy project, we modified our single-cylinder test engine to support probing the combustion chamber with a neutron beam.

In 2020, we launched an online portal to provide our clients with increased access to real-time information about test projects underway in SwRI labs.

In 2020, we adapted existing laboratory equipment to support client demands and the continuing shift of automotive engineering toward electric and hybrid-electric platforms. For instance, we modified our bearing test rig to extend hybrid-electric testing technology from light vehicles to heavy-duty trucks. As hybrid powertrains switch back and forth between the internal combustion engine and the electric motor, the frequent engine stops and starts can affect lubrication. These lubricants undergo unique cooling and heating cycles, creating different performance requirements than in traditional engine powertrains. Using internal funding, engineers designed the test rig to enable cutting-edge lubricant and bearing tests using multiple oil film thickness probes and an in-line torque meter to measure bearing performance.

In addition to updating equipment, we also installed new chassis dynamometers optimized for all-wheel drive (AWD) and electric vehicles. These facilities perform mileage accumulation and durability testing as well as efficiency evaluations, necessary as vehicle fleets move toward more AWD and electric vehicle (EV) applications. We are also installing regenerative dynamometers that convert the mechanical energy from engine testing to electricity that can be returned to the Institute grid. This represents a modernization of capabilities, as well as a reduction in our energy consumption.

SwRI’s powertrain testing laboratory became the world’s first lab qualified to evaluate greenhouse gases from hybrid-electric trucks this year. These engines, although low in traditionally controlled emissions, still produce carbon dioxide gas. Reducing or even replacing engine operations with an electric motor can reduce CO2 emissions. We are also investigating future hybrid concepts to make the internal combustion engine and the electric motor an integrated unit, where neither works well without the other.

In related research, engineers used internal funding to examine the unique demands that extremely high-rpm electric motors place on automotive fluids and the unique demands that EV powertrains place on lubricants. Many automakers currently use conventional fluids in electrified powertrains, which may not be optimized for the EV environment. The main concerns with EV fluids are electrical and thermal conductivity, corrosion, material compatibility, oxidation and extreme pressure performance.

At our Ann Arbor Technical Center, SwRI is testing the efficiency of electric vehicles by measuring voltage and current throughout the powertrain while simultaneously measuring torque and speed directly at the wheel hubs.

Using connected vehicle technology, SwRI engineers develop applications where traffic signal controllers and vehicles communicate via radios. The alert on this tablet warns drivers of a traffic signal change.

Additional critical features of electric and hybrid vehicles are their energy storage systems. SwRI operates a 12,000-square-foot Energy Storage Technology Center®, one of the largest state-of-the-art lithium ion battery and energy storage systems research facilities in the country. We provide the automotive and power generation industries with electrochemical energy storage and engineering expertise to research, develop and evaluate batteries, battery chemistries, battery cells and battery packs used in EVs and grid storage applications. Our energy storage research program is examining immersive coolants and fast-charging capabilities to improve hybrid-electric vehicle operation. Keeping batteries cool adds life and improves the power output of the electric vehicle’s energy storage system, and rapid charging makes electric vehicles more competitive in the marketplace compared to easy-to-refuel gasoline and diesel vehicles.

In another hybrid vehicle project, an SwRI-led team demonstrated how connectivity and automation achieved a stunning 20% improvement in efficiency on a 2017 Toyota Prius Prime, a larger improvement than single-digit increases typically available to engine developers. The program met efficiency goals without changing the powertrain or compromising emissions, safety or drivability using new tools such as eco-routing, eco-driving and power-split optimization. Drivers using a navigation tool can set their destinations and see routes that may add minutes to their arrival time but are more fuel-efficient. While the technology is appealing to the eco-minded consumer, for delivery and service fleets, this 5–10% savings in fuel consumption can add up to millions of dollars in savings each year.

Transportation

Connected vehicle (CV) technology is also a cornerstone for tomorrow’s automated vehicles, which use sensor and localization technologies to navigate and maintain roadway position. SwRI fuses these technologies for diverse applications, from passenger cars to military vehicles designed to keep soldiers out of harm’s way. Our work on the robotics technology kernel is helping to expand automation on military ground vehicles.

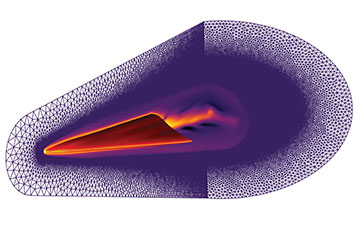

This large-scale computational fluid dynamics simulation shows a hypersonic glide body at Mach 14. The color scale around the flight body indicates the high heat flux of the local gas environment.

In 2020, SwRI researchers used integrated corridor management solutions to improve traffic incident response through data fusion and analysis of third-party and crowdsourced data.

SwRI expanded our radioactive tracer capabilities to make highly accurate real-time wear measurements for engine components.

Connected vehicles communicate with the infrastructure and other vehicles to enhance mobility, safety and fuel efficiency. In 2020, we continued to support the installation of Georgia’s comprehensive CV system in the Atlanta area, including dedicated short-range radios deployed at more than 400 intersections, with another 250 in progress and plans for over 1,000 more. SwRI is working with local agencies to develop a range of CV applications such as signal phase countdown, green speed recommendations, red light violation warnings, and signal prioritization and preemption for transit vehicles and emergency responders.

Connected vehicle technology is often deployed via advanced traffic management systems (ATMSs) that help national, state, rural and municipal entities manage mobility, safety and environmental impacts from roadway traffic. Hundreds of billions of dollars are spent on the infrastructure every year; however, it’s financially impossible to build our way out of congestion. Instead, 11 states and Puerto Rico use SwRI’s ATMS technologies and services to help traffic flow more efficiently and safely. In 2020, SwRI used machine learning and computer vision algorithms to develop Active-Vision™ software to reliably detect wrong-way drivers in real time based solely on video from roadside cameras. Active-Vision software also tracks vehicle speed and precise GPS coordinates in real time and can detect changing weather conditions, incidents and other anomalies on the roadway.

In 2020, the National Cooperative Highway Research Program and Transportation Research Board awarded SwRI projects to address cybersecurity concerns associated with transportation management systems. SwRI is researching the unique challenges that informational and operational technologies face to help guide state transportation agencies on cyber-incident management. SwRI is also helping improve automotive cybersecurity for commercial and military customers, developing techniques to secure over-the-air updates for vehicle firmware.

In other highway safety research, SwRI’s onsite crash test facility recently added a median ditch to test cable safety barriers commonly used on divided highways to capture or redirect errant vehicles and prevent head-on collisions. Standards released in 2016 require cable barriers be tested in a ditch scenario.

In the aerospace arena, SwRI is using unique facilities and capabilities to explore how hypersonic vehicles traveling in excess of Mach 5 react to extreme heat and friction. We have machined and characterized carbon-carbon heat protection materials and improved fabrication techniques using probabilistic methods. Using our two-stage light-gas gun, we use advanced optical and spectral diagnostics to quantify the signatures of small-scale flight vehicles launched up to Mach 20. Using internal funds, we are expanding our NPSS® software for conventional aircraft engine simulations to hypersonic flight vehicles.

For more information visit Automotive & Transportation.