About the Header

As energy companies explore blending hydrogen into natural gas streams to curb carbon emissions, SwRI is studying the possible impact on existing infrastructure, evaluating natural gas pipelines and flow meters to assess their performance with blended gases.

The United States and many other countries have set goals to reach carbon neutrality by 2050 or sooner. To achieve this target, entire economies will need to decarbonize, including their energy sectors. Transitioning gradually from fossil fuels using carbon-neutral hydrogen gas could offer a natural progression away from carbon-based fuels.

Blending hydrogen into natural gas streams could curb carbon emissions for conventional natural gas power generation using existing national pipeline infrastructure and conventional power generation machinery. However, steel pipelines are susceptible to a phenomenon known as hydrogen embrittlement. SwRI is evaluating how hydrogen affects the mechanical performance of pipeline materials by performing mechanical tests in high-pressure hydrogen gas environments for fracture-mechanics-based integrity and fitness-for-service assessments to support these efforts.

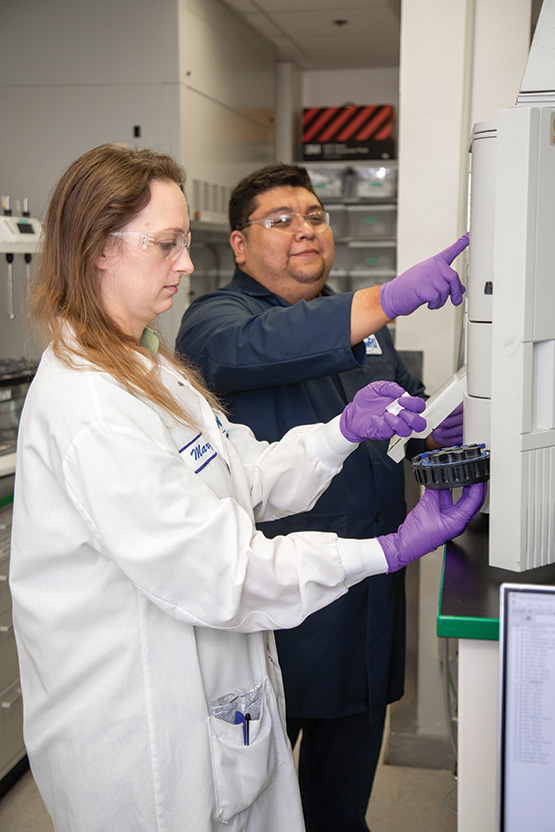

In 2023, SwRI also investigated using existing natural gas distribution infrastructure to supply homes and businesses with natural gas blended with carbon-neutral hydrogen, as gas companies propose using these gas blends in the next decade. Because the density of the resulting blends would be significantly different than natural gas alone, flow meters calibrated to measure natural gas will have some error when measuring blended gases. It is critical to accurately quantify the energy transferred from the gas distribution companies to individual customers once hydrogen is added. In 2023, SwRI assessed the performance of four common flow meters using blended gas, measuring the density and energy content of the blends at common temperatures and pressures.

SwRI chemists are collaborating with professors from Tecnológico de Monterrey in Mexico to develop techniques to recycle and reuse industrial rubbers and plastics. Researchers characterize the industrial materials to develop biobased compounds and create environmentally friendly raw materials.

As home to a 10-kilowatt pumped heat energy storage demonstration facility, SwRI is developing and validating the operations and control system technology.

Supercritical carbon dioxide (sCO2) is carbon dioxide held above its critical temperature and pressure, where it has high density and fluid properties that change rapidly with temperature. These characteristics enable highly efficient and compact power generation systems but make turbomachinery and component design challenging. SwRI is a leader in sCO2 power cycles, collaborating with the Department of Energy on more than 20 projects demonstrating the feasibility of the power cycle and developing machinery and components to support it. The STEP Demo project featured in the front of the report is a culmination of this research, which is expected to lead cleaner and more efficient energy production.

In 2023, SwRI scientists traveled to Turkey as part of the National Science Foundation’s Geotechnical Extreme Events Reconnaissance program to observe and document liquefaction-related damage following a series of devastating earthquakes in February.

As the renewable electricity market grows, so does the need to develop cost-effective long-duration energy storage technologies to stabilize electrical grids integrating variable, intermittent green energy sources, such as wind turbines and solar photovoltaic farms. SwRI is developing new technologies, including the successful commissioning and operation of a pumped thermal energy storage demonstration system. Engineers are also designing cryogenic turbomachinery for liquid air energy storage, creating pump-as-turbine designs for geomechanically pumped storage and advancing aerogel technology to improve hydrogen storage density. The team also developed a software tool through the internally funded “Project Z,” evaluating zero-carbon generation and storage technologies to optimize pathways for net-zero electricity production at SwRI’s San Antonio campus.

The electric utility industry is striving to modernize the electric grid to more effectively match supply and demand, which can fluctuate drastically over the course of days, weeks and seasons. The industry is experimenting with storing excess energy in batteries. However, the safety and long-term effects of using batteries this way are unclear. As part of a recently completed, 28-month Battery Energy Storage System for Electric Grid joint industry program, SwRI engineers used internal funding and in-kind member support to develop a unified model to chart the performance degradation, capacity and fire hazards associated with using a lithium-ion cell for mixed grid duty. SwRI developed a grid-connected research battery to support the program, and the models developed are available for evaluation and licensing in early 2024.

SwRI has created and validated innovative methods to evaluate the performance and durability of sand screens used in oil and gas production wells, characterizing erosion as particles pass through the screen gaps.

Since 1987, SwRI has operated the Center for Nuclear Waste Regulatory Analyses (CNWRA®) as a federally funded research and development center to assist the U.S. Nuclear Regulatory Commission (NRC) with responsibilities associated with radioactive waste storage, transportation and disposal. Under contracts renewed in Spring 2023, CNWRA experts provide the NRC technical assistance and research support on advanced reactor fuel, artificial intelligence, defense radioactive wastes, commercial low-level wastes and other technical areas. CNWRA scientists have also supported the NRC’s natural hazard assessments, including technical support for the development of seismic engineering guidance for nuclear facilities in the U.S. Beyond its primary mission of providing technical assistance to the NRC, CNWRA staff led a committee evaluating earthquake hazards at a nuclear power plant site in South Africa. SwRI staff are also collaborating on a worldwide next-generation liquefaction project to develop models to better predict the triggering and consequences of earthquake-induced soil liquefaction, when water-saturated but otherwise solid soil temporarily behaves as a viscous liquid in response to seismic shear waves.

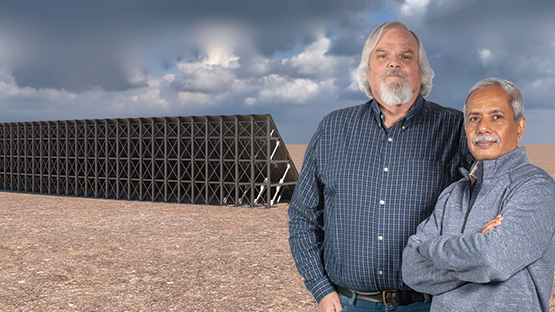

SwRI developed the m-Presa™ modular structural steel buttress dam designed to reduce the time and expense associated with constructing reservoirs for closed-loop pumped storage hydropower systems for long-term energy storage.

Using internal research and capital equipment funding, SwRI completed the design and fabrication of a 30-inch diameter deep sea simulation chamber for evaluating the quality and operation of components for oil producers, pipeline and subsea parts manufacturers, and the U.S. Navy.

In 2023, SwRI developed a process for converting wood pulp into a refinery feed from a renewable carbon source. A life-cycle assessment performed by the client found that the SwRI process was carbon-negative as well.

SwRI evaluated the erosion resistance of sand control screens used in oil and gas production wells to keep formation and fracturing sand in the reservoir while allowing fluids to be produced. Fine formation sands, smaller than the screen gaps, periodically pass through the screens, causing screen erosion that can eventually lead to failure, potentially endangering production equipment. SwRI research evolved to include advanced 2D and 3D microscopic image processing techniques to characterize screen performance, quantifying the material loss and how it changes over time, which allows operators to schedule maintenance or decommissioning before a failure occurs.

SwRI provides exploration and production support to oil and gas companies, using structural geology and geomechanics to optimize hydrocarbon production. SwRI recently initiated the third phase of our Permian Basin Consortium, integrating outcrop and core-based observations of mechanical stratigraphy and natural deformation to support the energy industry.

For decades, SwRI has created custom systems to create high-pressure subsea and downhole conditions, commissioning pressure vessels in six different countries to specific client needs, jurisdictional requirements and ASME standards. The Institute is now home to a 30-inch-diameter test chamber with a unique geometry and fast-acting closure. Developed with internal research and capital improvement funding, this chamber will support evaluating the quality and operation of components developed by oil producers, pipeline and subsea parts manufacturers, and the U.S. Navy.

SwRI engineers and scientists develop and validate novel processes to upgrade and refine fuels and other high-value products from unconventional sources, using custom catalysts, pilot plants and laboratory facilities. In 2023, SwRI supported the development of a process for converting wood pulp into a refinery feed. These chemicals are developed from a renewable carbon source instead of fossil fuels. A life-cycle assessment performed by the client found that the planned commercial process was carbon-negative as well.

Water quality and availability remain important global and local concerns, particularly in association with climate change. SwRI continues to focus on water resource management issues across Texas and in the Mexican border region using field- and lab-based hydrochemistry, applying remote sensing techniques to better characterize ecosystem health and hydrologic vulnerability.

In a good stewardship program for the Department of Energy, SwRI is collecting potentially hazardous radiation sources from university labs and hospitals. The Institute uses a high-capacity crane and other facilities to repackage and prepare the materials for transport.