Background

Vibration analysis is commonly used for health monitoring and troubleshooting issues with machinery such as pumps, compressors, gas turbines, and electric motor drives. Recorded measurements from vibration sensors are normally studied using Fast Fourier Transform (FFT) based frequency analysis; however, FFTs are not well suited for analysis of quick transient waveforms. Time-frequency based techniques have more promise, but these analysis techniques have not been widely applied to troubleshooting machinery vibration problems.

Approach

Figure 1: Solid model of the benchtop vibration test rig.

The primary goals of this project are to identify and develop advanced signal processing techniques for troubleshooting transient machinery vibration issues for motor-driven trains. Specifically, the project investigates the use of vibration instrumentation combined with motor current sensors to troubleshoot transient events. A benchtop scale vibration test rig will be developed to simulate and detect various transient machinery faults using the developed techniques.

Accomplishments

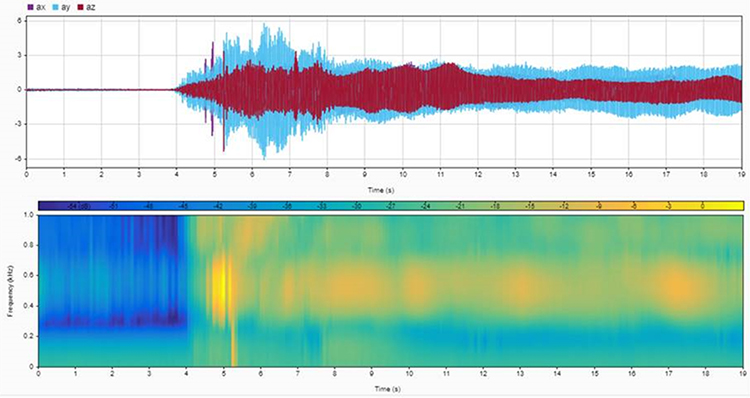

The project has identified several time-frequency analysis techniques that show promise for application to machinery fault detection and troubleshooting. Continuous wavelets have been identified as the most promising technique through preliminary analysis of a sample transient waveform, shown in Figure 2. Detailed design of the benchtop test rig shown in Figure 1 is complete, and the project has progressed to hardware acquisition and rig build up. Once commissioning of the test rig is complete, it will be used to simulate various machinery faults for analysis and detection with the time-frequency techniques. Anticipated test faults include excessive unbalance, misalignment, rub events, shaft bow, as well as other motor and bearing faults.

Figure 2: Continuous wavelets have been identified as the most promising technique through preliminary analysis of a sample transient waveform.