Our innovative particle extrusion processes produce capsules down to sub-micron with small particle size variances. We can operate with complex thermal profiles. Our fiber extrusion processes can produce single or multiple fibers with diameters down to the nanometers. We have developed the ability to produce matrix fibers, core-shell fibers, and multilayer, fibrous structures.

We use several particle and fiber extrusion techniques to solve product performance requirements, including:

- Stationary nozzle

- Centrifugal extrusion

- Vibrating nozzle

- Submerged nozzle

- Electrohydrodynamics

- Single or twin-screw extrusion

- Microextrusion

Extrusion processes produce matrix or core-shell morphologies, depending on nozzle configuration. Particle extrusion processes produce narrowly distributed particles. Our scientists have innovated particle extrusion processes to:

- Produce capsules down to sub-micron sizes with small particle size variances

- Operate with complex thermal profiles

- Support production capacity

Fiber extrusion processes produce single or multiple fibers with diameters down to several hundred nanometers. We have devised fiber extrusion processes to produce:

- Matrix fibers

- Core-shell fibers

- Multilayer, fibrous structures

Extrusion Applications

- Narrow size distributions

- Core-shell morphologies

- Gas, liquid or solid cores

- Variable shell thickness

- Variable payload composition

Extrusion Characteristics

- Sizes from 1 micron to 10,000 microns

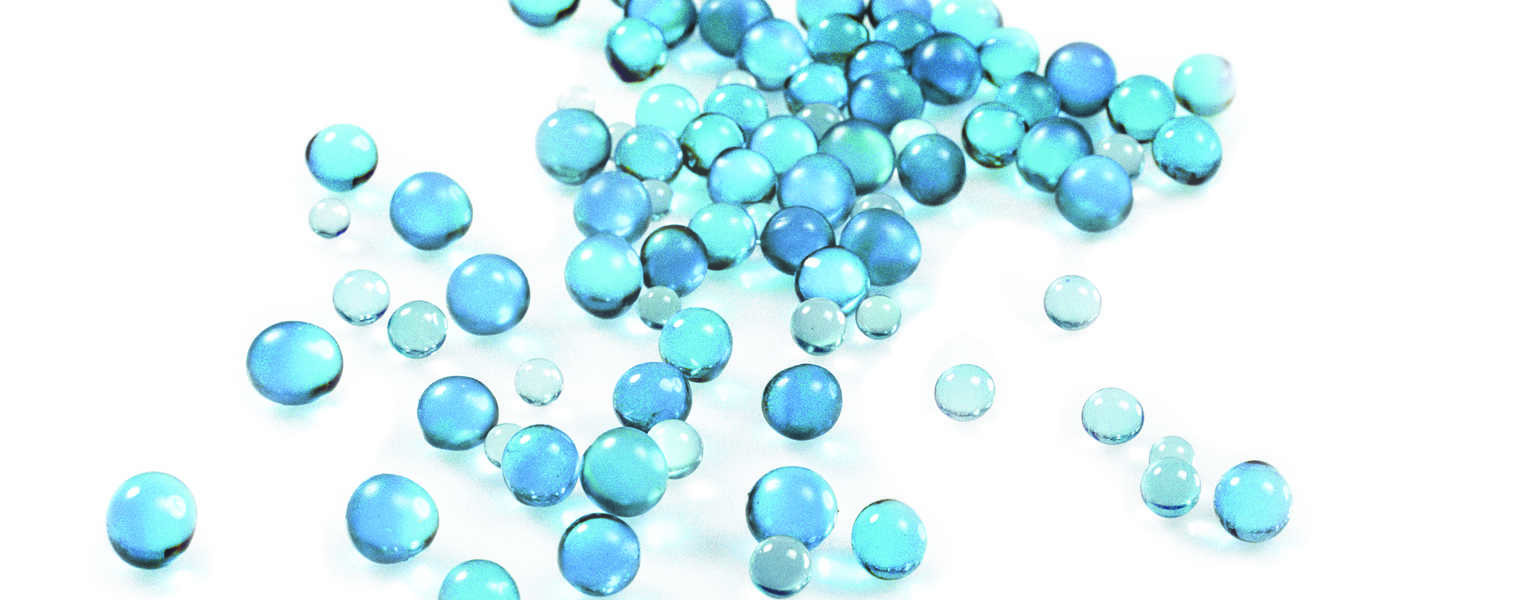

- These oil-filled microcapsules were produced with centrifugal coextrusion.

- Narrow size distribution

- Material versatility

- Scalability and high production capacity

- Continuous production