How to Listen

Listen on Google Podcasts, Apple Podcasts, or via the SoundCloud media player above.

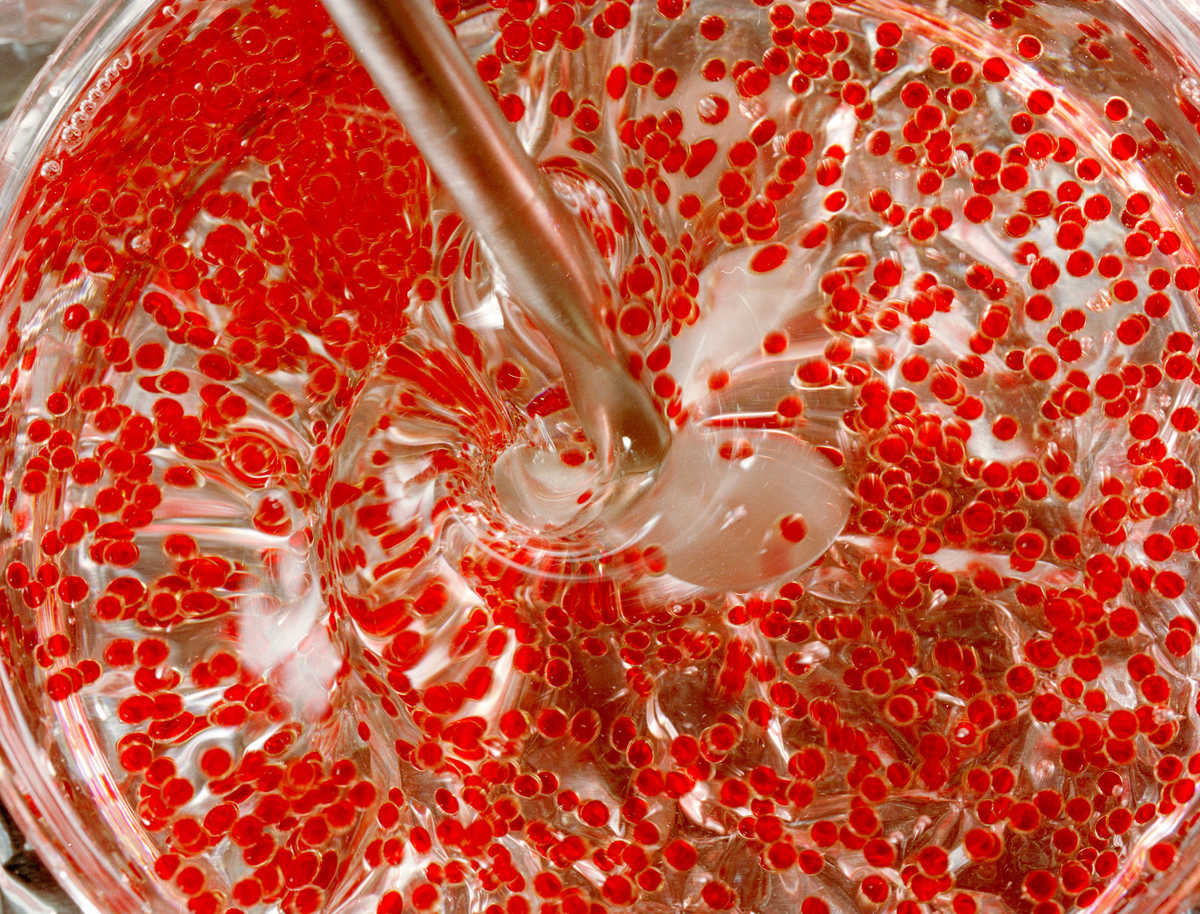

As you go about your day, you likely encounter microcapsules or microspheres everywhere. From your morning shower shampoo to your nighttime sleep aid, microencapsulation is working to improve your life. SwRI’s microencapsulation experts create custom, controlled-release capsules for a variety of products. Since 1949, SwRI has tailored this tiny technology for a broad spectrum of industries, including food, pharmaceutical, cosmetic, agricultural, veterinary medicine, biomedical and more.

Listen now as SwRI Scientist Dr. James Oxley discusses the process of microencapsulation, the wide range of products that contain hidden capsules, the history of the mighty microcapsule and what the future holds for this technology.

Visit Microencapsulation to learn more.

TRANSCRIPT

Below is a transcript of the episode, modified for clarity.

Lisa Peña (LP): From toothpaste and shampoo to lawn fertilizers and car wax, many products have this tiny technology in common. Today, we explore microencapsulation, what SwRI's customized controlled capsules do, how they're made, and what the future holds for these mighty microcapsules. That's next on this episode of Technology Today.

[MUSIC PLAYING]

We live with technology, science, engineering, and the results of innovative research every day. Now, let's understand it better. You're listening to the Technology Today podcast presented by Southwest Research Institute. From deep sea to deep space, we develop solutions to benefit humankind. Transcripts and photos for this episode and all episodes are available at podcast.swri.org. Share the podcast and hit that Subscribe button on your favorite podcast platform.

Hello, and welcome to Technology Today. I'm Lisa Peña. Microcapsules are everywhere. You might be most familiar with your vitamin or over-the-counter medication capsules, but they're also hidden in other products we use every day. SwRI has a long history of microencapsulation research and development. Institute staff scientist Dr. James Oxley is here to tell us more about customized and controlled capsules. This is Jamie's second visit with us. He shared his microencapsulation breakthrough story back on episode 14. So great to welcome you back, Jamie. Thanks for being here.

Dr. James Oxley (JO): Great. Thank you for having me. I appreciate it.SwRI develops encapsulation technology at the micro- and nanoscales for a broad range of industries, including food, pharmaceutical, cosmetic, consumer, personal care products, agricultural, biomedical and much more.

LP: So, Jamie, clients worldwide come to you and your team with unique challenges that only microencapsulation can solve. So let's start with a basic understanding of the process. What is microencapsulation, and what do microcapsules do?

JO: Sure. Excellent question, of course-- a good place to start. So, it's in the name. So, it's a capsule, first and foremost. So you can think of a space capsule or a tiny drug capsule that you might take. But we're on the micron size. So we're anywhere from below one micron, so nanometers, up to hundreds of microns, maybe even a millimeter-- so, coarse sand down to something you can't see. And they're capsule, so they're containing something. And the most common size might be on the order of tens of microns, about the width of a human hair. And so these are engineered particles where you can have different morphologies, meaning a microcapsule. So that might be-- think of a water balloon where you have a liquid inside of a latex shell, but shrink it down to, again, 10, 20, 30 microns, almost too tiny to see. Or you can have a matrix particle or microsphere. And my analogy there is like a ball of chocolate chip cookie dough or a blueberry muffin, and the blueberries or the chocolate chips are the drug or the fragrance or the flavor that you're trying to encapsulate. And then the matrix around that is keeping it into the sphere. And so those are the two morphologies. And when I talk about encapsulation, it's both of those. And the reason to make these types of capsules is to control the release. So you can think about-- and we'll talk about carbonless copy paper probably later in the podcast. But if you want to control release of a fragrance-- scratch and sniff is a good example. I think we've all had that book where you scratch the blanket or the fruit or something like that and smell it.

LP: Childhood memories.

JO: That's right, and you're controlling that release. And so it doesn't release until your fingernail reaches over it and breaks those capsules. And so plenty of examples that we'll go through, but controlling release is really one of the main functions of encapsulation.

LP: All right, so, capsule, think water balloon. That water in that capsule, that's the balloon. Microsphere, we're talking about the product embedded, like a cookie dough or blueberry muffin, as you mentioned.

JO: Right.

LP: All right, thanks for explaining that. Great explanation. So, what are these capsules made of?

JO: So, this is where it gets fun and why I have a job because there's hundreds if not thousands of materials that we can make capsules out of. Most commonly, especially in the food and pharmaceutical space, it'll be something close to a natural material-- so, lots of either cellulose-based materials. Starches are used quite a bit, especially in flavors like maybe the flavors you might see on a Dorito chip. Those little colored specks are usually spray dried flavors that have little bits of flavor oil in them. You can also get into synthetic materials. So, melamine formaldehyde is a common one. If you've ever used a Magic Eraser, same type of polymer there. But we're using that as the shell of our little micro balloon. Or nylon-- I think we're all familiar with what nylon is in clothing. Same type of polymer, but to put that onto the surface of a pesticide droplet so that when it's applied to a field, it releases that pesticide more slowly.

LP: So it really depends on what the end use is going to be, which determines what the capsule is made out of.

JO: End use as well as the regulations in that industry. So, most of us don't want to eat nylon or melamine formaldehyde. So you're not going to have those capsules in your foodstuffs. That's where you usually use natural materials like either cellulose or gelatin or the starches or something called polysaccharides, like something called alginate, which has come from the seaweed.

LP: All right, well, you just gave us a good idea of the range of industries that use microencapsulation, but there are so many more. People might be surprised in what industries capsules pop up. Will you give us a picture of what the range is for microencapsulation?

JO: Of course, yeah. And this is part of what makes my job fun is that diversity. So, the main categories are pharmaceuticals, nutraceuticals-- so those kind of taking nutrients and delivering them in a pharmaceutical fashion-- food, cosmetics, consumer products, paints and coatings, agricultural, industrial, military applications. So, anywhere you might want to control an ingredient, capsules are used. And so some common examples that you may not be aware of, one is chewing gum. Some of the most patented inventions out there in the encapsulation space are in chewing gum because you need to control that flavor. You don't want your flavor to come out too soon. You put the chewing gum in, and the flavor is gone in a minute. You want it to last and sustain. You want to control that release.

LP: So, like, flavor crystals.

SwRI Scientist Dr. James Oxley conducts testing in one of the Institute’s laboratories where different microencapsulation techniques are performed. SwRI is a pioneer in the field of microencapsulation, researching and developing microencapsulation technology since 1949.

JO: Flavor crystals, yep. So, those crystals can be engineered for controlled release and be encapsulated. There's gums on the market that change flavors halfway through. So, they start berry and go mint or vise versa. Other products-- if you've ever used a Kindle, one of the original kindles, they use what's called an e-ink display. And so that display is not like your conventional LCD or iPhone display. Each pixel is actually a microcapsule, and that capsule, like a little water balloon. But now, that water balloon contains white pigment and black pigment. And then depending on the charge placed across that capsule, the white or the black comes to the surface, making it a reflective display, very little energy. And that's why when you, quote unquote, turn off your Kindle, the display remains because that pigment is still there. And so you're really relying just on the energy to change the picture rather than to sustain the picture, unlike a traditional display. Other examples-- I think we all drive cars, right? If you've ever see those nuts or bolts with a little bit of paint on the tip, that's called Loctite, and that paint contains little capsules of a glue. So when you screw in the nut or bolt, seals it in. The nut's not coming out. The bolt's not coming out. Your car is going to stay together. You're going to make it to work on time.

A few other examples. Deodorant-- hopefully, we all use it. But you want your deodorant to last all day. And so you can have encapsulated fragrances that release over a 12, maybe even a 24 hour period. And so they have an encapsulated fragrance, that micro balloon again. And it slowly diffuses out throughout the day rather than quickly evaporating because fragrances are very volatile. And so they will evaporate without any control mechanism in place. You don't always want something to release. So if you think about some beer cans on the market that have colored mountains on the front-- you know, I don't think I have to name who has beer that's as cold as the Rockies. But those Rocky Mountains are blue when the beer is cold, and they're gray when it's warm. And those mountains, that ink, contains capsules with a liquid crystal material that is blue when it's solid and gray when it's liquid. And so there, you want to control the release from the fact that you don't want it to release at all. You don't want that ink running down on your hands as the can warms up. And then finally, a couple of last examples-- Pop Rocks, if you remember that candy from when you were a child or if you have kids. That's an encapsulated gas. And so there, you're controlling the release as soon as it gets in your mouth and your saliva starts to melt the sugar and you get that little pop. And then you can do your own encapsulation at home if you ever used Febreeze. So, Febreeze is a product made with what's called cyclodextrin. So it's a cyclic molecule, a ring. And when you spray it, those malodorant molecules are encapsulated through a molecular encapsulation process into that cyclodextrin and kind of take it out of the air so you don't smell it anymore.

LP: All right, when we call these mighty microcapsules at the beginning, we weren't kidding there. It sounds like there's really nothing microcapsules can't do. So, huge range there, so many products. Can you name a well-known product or products that use microencapsulation developed here at SwRI?

JO: Yeah, I can name at least one product. A lot of our developments are commercially funded, covered by NDAs. So I can't talk about some of the more exciting ones in many cases. But one that is out there is called Zilretta. It's an inter-articular injectable product. So it's a pharmaceutical. And it's an encapsulated ingredient that when you inject it into your knee-- which, that sounds painful on its own. But it's meant to be a long acting release of pain relief for arthritic pain for arthritis. And so that was developed in part here at the Institute using some of our processes.

LP: All right, so many products out there with SwRI microencapsulation stamp. And there are various microencapsulation techniques. So, how are they made?

JO: Yes, there's at least two dozen processes we have in-house on the lab to pilot scale at the Institute. That makes us quite unique from the standpoint of companies that do encapsulation. I generally divide them into four categories. One is called atomization. So you're atomizing. You're spraying. So, a very simple analogy is if I take a solution of what I want to encapsulate and spray it out of a nozzle into a hot air on a sunny warm day, the water might evaporate, and you end up with dry powder. That would be our capsules. A second version is spray coating. So there, we spray paint individual particles. So you take a particle down to hundreds of microns in size, and you use a device to spray a coating onto each particle and make a core shell, almost like an M&M but smaller. A third category is called co-extrusion, where you're extruding two fluids out of a concentric nozzle. So think about putting a hose inside of a hose. And your inner hose has what you want to encapsulate. The outer hose has what will become your shell. And you do it in a controlled fashion to make a droplet inside of a droplet, and you harden that outside droplet to make a capsule. And then the final and fourth category is emulsion-based processes. So you're emulsifying oil into water. So if we've made salad dressing, you're putting oil into vinegar or whatever combination you want. Those don't always emulsify it well. So, encapsulations figure out better ways to make these emulsions. And then each of those emulsified droplets, we form a shell chemically or maybe through some sort of physical method to make our capsules.

LP: OK, and what special equipment or spaces do we have here at SwRI to develop this microencapsulation technology?

SwRI Scientist Dr. James Oxley pushes the boundaries of microencapsulation research and development, looking ahead to the future. He says the field is trending toward smaller, biodegradable capsules and lower cost encapsulation.

JO: Yeah, so we're spread across about seven buildings, I think up to 40,000 square feet. As I mentioned, two dozen processes, and each of these processes require their own special piece of equipment or multiple pieces of equipment. So atomization, we have several what are called spray dryers. And as the name implies, you spray and dry your powder. We also have some very unique what are called spinning disk systems. And so that's a process that was developed here at the Institute back in the '40s and '50s. We have fluid bed coating equipment. That's for the spray coating. So imagine a lottery ball machine where you see the lottery balls floating around, the little ping pong balls. But now instead of ping pong balls, they're tiny powders. And that's what we fluidize, float those around. And as they're floating around in that bed of air, we spray on our coating. And so we have several pieces of equipment that are capable for that process. For co-extrusion, that's extruding to liquids to form a concentric or a core shell droplet. There, we have what's called a vibratory nozzle system. So, imagine your hose inside of a hose vibrating at a certain frequency to get a very narrow droplet size formation. Or we have a new what's called a microfluidic chip system.

So, think something about the size of a microscope slide that has very small, intricate tubing built into it to make very small core shell droplets using this co-extrusion technology. And then finally, for the emulsions, there, we get less away from specialized equipment and more to classic chemistry equipment-- so, beakers, overhead stirrers, ways to make emulsions. Not as specialized in terms of cost and, I'd say, fanciness but very essential and very important to making some of the common encapsulation chemistries that are out there.

LP: In a recent presentation here at the Institute, you mentioned carbonaceous paper, different from carbon paper, was the first modern invention of microencapsulation. So, how are capsules with carbonless paper embedded in that paper? How did the use-- and then how did the use of capsules grow from there?

JO: Yeah, so it's a fun story. It started with the National Cash Register Company in Ohio. Fun for me, I should say, in the encapsulation space. And it was originally developed around using gelatin, that was the shell, and put it around a colorless dye called a leuco dye. So this is your micro balloon. And small enough to be put onto paper and not see it-- so you have your white sheet of paper. You have this balloon that contains a dye. And then when pressure is applied, that balloon breaks. That dye comes out and changes from colorless to colored based on what's in the paper. So it could be black, blue, red, something like that. And they are made using an emulsion process. So you end up with this nice, almost looks like a white paint. And that's painted onto the paper during the printing process. And so that's how you end up with your carbonless copy paper. From there, capsules evolved as they looked at different formulations. So, gelatin is a natural material, inconsistent source that runs into inconsistent production. And so it'd be nice if there were a synthetic version. So NCR, National Cash Register, came up with a synthetic version.

From there, 3M, they wanted to compete. They came up with their own synthetic version. And so you start to have this more innovative process for different shell materials, and then applications followed that as well. So, agricultural came onto the scene in the roughly 1970s and controlled release of pesticides. So you could apply pesticide, apply less of it, control the release of it. So, after a rainstorm, it doesn't all wash away and continues to release. In the '80s, you start to see pharmaceuticals, say, hey, this is a neat trick. Can we use controlled release for the pharmaceuticals that we consume or inject or put on our skin? And so that's where you see a lot of money and innovation come into the modern encapsulation era with different formulations, different way to design capsules, and different materials to give them different properties.

LP: It's interesting to hear about this history because something like capsules, they're just part of our lives these days. We don't really think about them as being a technology or having science behind them. But there really has been decades, teams of people, teams of research. And I think we just take them for granted, right?

JO: Absolutely, yeah.

LP: Just use them every day. So, we have a long history with the technology here at the Institute, and SwRI has been working in this area since 1949. So, SwRI opened in 1947. So, just a couple of years later, we were in this space. So, will you walk us through the history of microencapsulation here at the Institute?

JO: Absolutely, yeah, and I pulled early information of this from Harold Vagtborg's book Story of the Southwest Research Center. And he first pointed out that in 1949, a scientist named Jean Pathus-Labour patented a process to basically make a dry or powdered gasoline so, encapsulating gasoline. And the Institute's initial work was a lot in the automotive industry and things like that. So that's where that tie comes in. From there, we became known as a place of encapsulating odd, unique things because in the '40s and '50s, it was carbonless copy paper and pesticides. Well, what else could we make with capsules? And so we got more into other encapsulation processes. In the 1950s, Judson Swearingen patented a process for a type of co-extrusion. That's that droplet inside of a droplet.

In the 1960s, then George Somerville patented some work on spinning disk atomization, so a unique way to control atomized droplets and control size. And that's today still one of our founding processes that we use quite a bit for our clients. And then in the 1970s and '80s, expanded more and actually in the 1980s got into manufacture of microcapsules. So we were manufacturing encapsulated, I believe, fragrances for laundry detergent as well as some encapsulated water for a unique mining application to help cure an adhesive in the rods that are used to support mineshafts. And so we had some fairly large scale manufacturing capabilities, started to pare that back as we got out of manufacturing, and then in the '90s began to look more into pharmaceuticals, start to grow our what are called CGMP or good manufacturing processes to make clinical trial materials and then in the 2000s begin more into nano encapsulation and nanoparticles. And I joined in 2004, and we continue to grow in add to our capabilities. And so it's just been a slow and steady process.

LP: But what happened to gas capsules?

JO: I have no idea. I've heard that in part, they were used to make what are called fuel bricks. So I think in the '50s and '60s, I've seen some examples of literature from the Institute about these compressible fuel bricks. So, you load the brick in the car, and then it squeezes the gas out, but an easier way to handle gasoline. But it may be too late now. I hope--

LP: I'm just picturing just dropping a capsule in the tank and heading off.

JO: That would be nice, yeah.

LP: But we have since grown this area. It's a huge part of what we do. So many opportunities in this area. So, what is next in microencapsulation technology, and what does the future look like?

JO: Sure, and there are several challenges that I think will continue to be a big roadblock for scientists like myself. It's tough to encapsulate something and protect it from water, oxygen, and heat. So, those are kind of our big drivers in terms of how do we control release of those types of materials and those types of environments? But there are other trends that we're following. One is smaller capsules. A good example is thinking about vitamin waters or nutrient waters. The consumer wants something that has water in the name to look like water. They want it to be clear. In order to do that, you have to have capsules that are below the wavelength of light so, nanometers in size. So a lot of our common chemistries that we might otherwise use are too big for that. And so there's a trend, whether it's for vitamin water or other applications, to go smaller. So that's one of the main trends. Another one is biodegradable capsules. So the European Union is on track to ban microplastics, and that will capture a lot of the classic encapsulation chemistry. I mentioned the melamine formaldehyde dye capsules used in fragrances, the nylon type capsules used in pesticides. Those are all going to be subject to these microplastic bans and have to be replaced by biodegradable materials. And so that's a big push right now that I'm sure we'll see coming to fruition in the next few years. More economical approaches-- everybody wants to pay less for their products.

So, how do we do the same type of encapsulation or same type of a controlled release with less money? And so there is work underway to figure out, is it materials? Is it better throughput? How do we make savings there? And then personally, where I see some of the future going in addition to solving those challenges is some of the processes to make capsules. I mentioned microfluidic systems earlier, these little chip-based flow reactors is what they were originally used for. Using those to make capsules, and a big barrier to that right now is scalability, meaning with a spray dryer I mentioned at the top that spraying something and drying it. Largest spray dryers in the world are cranking out 30 tons an hour of material. That's a lot. That's for your milk powder. These little chip devices, we're maybe a ton per month. So, there's a way to go before we get to any appreciable production capacity. But that's where we're headed because these chip-based systems give us more versatility and, I think, more opportunities compared to some of the other classic emulsion-based processes. So I mentioned at the top that this was actually your second time back. We had you on back on episode 14. I went back and listened to that episode and heard your segment. And you mentioned linseed oil there at the time. Do you have an update for us on that? Is that something being used in microencapsulation processes? It's not being used yet. So we do have patents issued in both the US and the European Union. And so it is available for licensing, and we're currently looking at some applications but no products yet, at least that I'm aware of, that are using the linseed oil. And that is a natural biodegradable material, which was part of the reason we looked at it.

LP: And part of the way things seem to be going.

JO: Yeah, exactly.

LP: All right, so I wanted to ask you. Do you have a memorable experience developing this technology or an R&D highlight you'd like to share with our listeners?

JO: Yeah, I'm going to go back to the beginning of my career at the Institute.

LP: All right, let's go back to the beginning.

JO: So to the origin story, right? So first, my background is inorganic chemistry, which is studying non-carbon chemistry-- very different from encapsulation. I had no encapsulation experience when I got here. I was brought in in part because I had worked with nanoparticles. And microcapsules, nano cap-- they're. Particles they're just highly engineered. So it was kind of a trial by fire, learn on the job, crash course in encapsulation. I was like, well, is this really something I want to do? You know, I'll be writing proposals the rest of my life, doing nothing but contract research. One thing in grad school I thought, writing a proposal for a grad school exam was like, I don't want to write proposals all the time. But got here and got into it, learned more about it. And one of the first leads that was handed to me was from a company interested in gene delivery to shrimp.

LP: Huh.

JO: So in the late 1990s, a new technology came out called small interfering RNA, so basically a gene technology to help kill viruses. Very effective and very targeted. But you have to get that sRNA to the virus and to whatever you're trying to treat. And there was a discovery of one of these technologies, one of these RNAs, that would help cure this deadly virus to shrimp. And as a shrimp farmer, you're like, this would be great. If I could prevent 90% plus of my shrimp from dying, fantastic. So they had found this gene technology, and they found it worked. But they had to inject each individual shrimp to get this to work. See, yeah, if you can imagine a big tank of shrimp, right, yeah, that's going to take a while. So they would say, is there a way we can put this into the feed? And so that was the problem they brought to us. They said, we have this big tank of shrimp. We have this great gene therapy. How can we just throw it into the tank and deliver it? Like, wow, OK. So we need to encapsulate. So I had to learn about shrimp anatomy, you know? How are they going to eat it? Are they going to breathe it in? Is it absorbed through their shell? I know nothing about shrimp. So I had to learn about shrimp anatomy. I had to learn about the sRNA technology. Again, I'm an inorganic chemist. This is gene delivery. This is biology. This is--

LP: Not in your wheelhouse.

JO: --not anywhere in my wheelhouse. But when you get a Ph.D. part of what you learn is how to learn. So you learn how to dive in and learn the stuff and then figure out how to put shrimp anatomy with gene delivery together into some potential solution for delivering to shrimp. And so put it together and talk with other colleagues, and we came up with a potential solution. I won't go into it here. Needless to say, it was a little bit too much for a common shrimp farmer to afford to do the development, and in hindsight, it was gene delivery, which is something that's still a very, very high bar and very difficult thing to do. But just the act of going through that taught myself, this is the place to be. This is a lot of fun. Even just coming up with the idea we didn't get to execute it. But just coming up with the idea and learning these new things, I was like, this is great. And so that's what happens every day. A client comes in with a new challenge, a new material, a new target a new way they want to control. And it's up to us to figure out how to do it. So, every day is a fun challenge.

LP: So it really set the foundation for you of what you could look toward.

JO: Yeah, exactly.

LP: So, do you know what was the outcome for the shrimp? Did they stamp out this virus?

JO: I have no idea. I haven't followed up since.

LP: I thought maybe you were the hero for shrimp everywhere.

JO: No, no.

LP: Really cool story. I love hearing-- we love hearing behind the scenes stories like this that really bring to light what the research and development is all about. So, thank you for sharing that story. So, you gave us a little glimpse with that story, but what do you enjoy most about this field?

JO: A lot of what I enjoy about this field is just what I described with the shrimp story. It's learning something new. But it's also the variety of what we get to work with. So, I've got multiple projects that span that range of pharmaceuticals and food down to paints and coatings. And so each of those applications, it's fun to learn about. And as part of that, I get to go out and see these facilities. So I've toured pharmaceutical facilities, seen how they make different types of drugs. I've toured snack food factories. You know, nothing like a fresh potato chip coming off the line right out of the fryer. It's fantastic.

LP: Who wouldn't want to see that?

JO: Exactly. Pet food factories, flavor and fragrance facilities, concentrated solar power plants-- I mean, it's a very diverse area where I get to see how these things are made, how they operate, and how they work and then feed that back in and learn from those. And actually, a lot of what we do is apply what we learn from one field to another. And so it's making those connections, I think, that's quite fun, and it's the breadth of what we do that makes that possible.

LP: So, does working in this field impact your product choices?

JO: 100%. Yes, yes.

LP: How so?

JO: So, a few examples. One is pharmaceuticals. Buy generics. I mean, so-- because we do a lot of work with pharmaceuticals and making materials for clinical trials, we're familiar with the FDA's requirements for CGMP and what they require for generics versus the name brand. They're the same. I mean, by law, the generic has to perform the same as the original. And if not, it's not going to be on the shelf. It's not going to be sold. And so save yourself some money. Get the generic. On other products, consumer products, buy powdered versions. I've learned water is a big enemy. Water is expensive to ship. It loves to grow microbes and bugs and bacteria. It makes it difficult to mix ingredients together and keep them stable if they would otherwise want to react. So for example, laundry detergents-- you can buy these nice liquid laundry detergent. They're concentrated, right? But there's certain components in laundry detergents that don't play well together once they're in water. Now, you want to get them in water to do what they want to do on the clothes, but during storage, they're not so happy.

If you can get them into powdered forms, which you can buy-- you can still buy your classic powdered detergents. Everything's separated. Everything's dry. Everything's happy. And so presumably better performance out of a dry product as well as better stability. I also know more about the ingredients list on the back of packages. We all pick up the box of cookies or chips or something like that and maybe looking at calorie counts or fat content. But you also start to see all these ingredients, you know? Like, wow, you know, red dye number five or polysorbate 80 or carrageenan. You start to see these weird names. And so I know what they all mean now. I'm not afraid of the list. I understand the list, and it does impact sometimes what I'll choose to buy. I usually don't avoid something because something is in it. I'm just curious more from an intellectual standpoint of, oh, that's how they made it stable. They used this surfactant or this emulsion stabilizer, or they're using this preservative. So it's empowered me, a little bit more knowledge. Also makes me a little more skeptical about product claims because learning how to stabilize and control release of ingredients, I know that some ingredients are a lot more challenging to stabilize than others, and they may say there's x amount of something in there, and that may have been the truth when they started and put it in. But that doesn't mean it's survived six months on the shelf at your grocery store or big box store. Or once you open it a month later, you may think it's still good, but it's not. So I've learned a lot about, at least in terms of stability, product claims and so forth and how those relate. And so I'm very skeptical about product claims and try and do my due diligence before I put any sufficient or appreciable money into it.

LP: So with labels, you see more to the story.

JO: Yes, absolutely.

LP: For sure. All right, well, Jamie, you've given us so much great insight today. We've learned a lot today. So what is the big takeaway today? What would you like listeners to remember about this field and about the mighty microcapsule?

JO: Sure, sure. So it's a hidden world of doing more with less. So, we want to control release. So if you think about it, in pharmaceuticals, part of the reason to control release is so you don't have to give as much, as big a dose. So if we can control the release of-- we'll just say aspirin. Maybe aspirin doesn't absorb well. And so tablets have 10 times the amount you need because you only absorb 10%. Well, if you can control the release, you can use less aspirin or less of a vitamin or less of a nutrient or less of a flavor or less of a fragrance. So we're using less to get the same effect. And that has ripples downstream in terms of sustainability, cost, environmental impact, and so forth. And so that's one of the big takeaways-- better stability, better efficiency. And it's not just about those ingredients on the back. So if you pick up a deodorant or shampoo or something that you might think has capsules, they're not going to advertise they have capsules. They'll have an ingredient list, and it's not about the ingredients. It's how the ingredients are put together. And so that's where capsules are hidden. And knowing how to see that is tough. You have to dig through the patents and things like that. So those two takeaways-- so, doing more with less, and then it's not about the ingredients. It's about how they're combined.

LP: All right, great insight, as I said. Capsules, in everything from our gum to our shampoo to our lawn fertilizers, as I said at the beginning. They're everywhere. So, SwRI's microencapsulation experts have such an important job and really a global wide reaching impact. And after our discussion today, I definitely have a greater appreciation for the small but hardworking capsule and the knowledge it takes to create them. So, thank you for sharing your insight and helping us understand this area of science.v JO: All right, thank you for having me. It was a pleasure being on the podcast.

And thank you to our listeners for learning along with us today. You can hear all of our Technology Today episodes and see photos and complete transcripts at podcast.swri.org. Remember to share our podcast and subscribe on your favorite podcast platform.

Want to see what else we're up to? Connect with Southwest Research Institute on Facebook, Instagram, Twitter, LinkedIn, and YouTube. Check out the Technology Today Magazine at technologytoday.swri.org. And now is a great time to become an SwRI problem solver. Visit our career page at SwRI.jobs.

Ian McKinney and Bryan Ortiz are the podcast audio engineers and editors. I am producer and host, Lisa Peña.

Thanks for listening.

[MUSIC PLAYING]

With more than 70 years of experience in encapsulation technology at the micro- and nanoscales, we can solve your application problems by using a wide variety of microencapsulation and particle coating technologies. Our full range of services includes feasibility studies, product and process optimization, pilot-scale production, equipment fabrication, and scale and system integration. Customized microcapsules and microspheres can be developed for dissolution due to heat, chemical change and friction, depending on application.