Background

SwRI’s Integrating Cavity Raman Ultraviolet Spectrograph (ICARUS) utilizes a novel yet proven integrating cavity approach to enhancing Raman measurement sensitivity with ×102 increases or higher compared to standard Raman techniques. For lunar and planetary mission operations a sample of regolith and/or icy volatile mixtures needs to be delivered inside the cavity, measured, extruded from the cavity, and then cleaned out to prepare for the next sample. Previous techniques for in situ planetary sample handling include sieving of samples prior to delivery to an inlet for an instrument, piezo-based vibration of the sieve and other components, and more recently a gas-puffing system for sample transport and regolith or dust particle removal. Our ICARUS design is readily adaptable to interface with such previous techniques, which we investigated in this project.

Approach

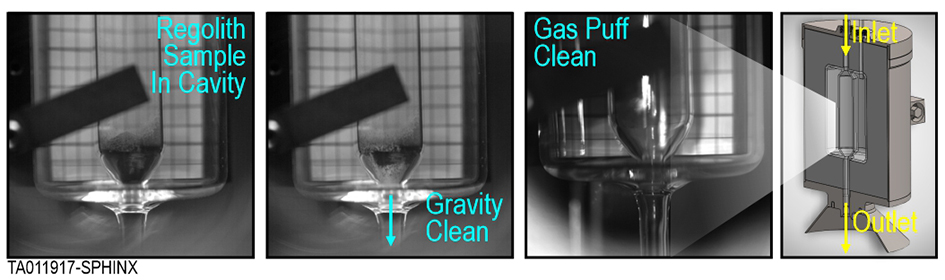

Our project demonstrates integrating cavity sample handling and pneumatic-cleaning approaches for lunar operations with a newly manufactured integrating cavity prototype. We designed and built custom interfaces to a sieve-covered inlet funnel, a piezo-based vibration tool to break nano-particle adhesion, and a gas-puffer cleaning mechanism. Testing of the integrating cavity’s ringdown timescale performance before sample delivery, during sample measurement, and after cleaning is the metric for success in preparing the cavity for subsequent samples.

Accomplishments

At the time of this synopsis report we have completed the design and have begun fabrication of several key parts of the interface to the sample handling systems. A new integrating cavity glass insert was customized to attach to a manifold on the integrating cavity housing lid that contains the piezo-based vibration mechanism and an inlet tube for gas flow from the gas-puffer mechanism. The gas-puffer test mechanism was successfully assembled and tested, following the advice and designs from our partners at Honeybee Robotics. A prototype funnel has been developed. The manifold on the cavity lid will be combined with the new glass insert after present machine shop fabrication is completed, and we’ll soon be ready to continue with the assembly of a new integrating cavity system with these sample handling component interfaces in place.

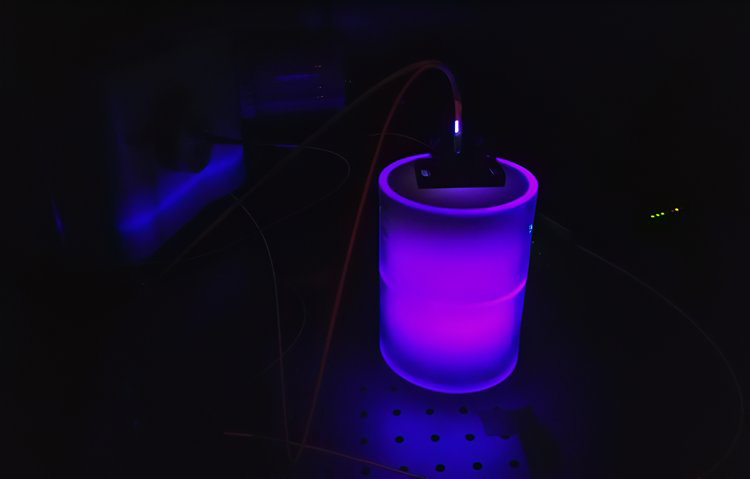

Figure 1: Functional prototype of an Integrating Cavity Raman Ultraviolet Spectrograph (ICARUS) cavity operating at SwRI with laser light input.

Figure 2: Photos of inner glass cavity with JSC-1A sample, emptied by gravity, and gas-puffed clean.