Battery modeling and simulation optimize battery systems to advance safety, performance and reliability. Computer aided engineering (CAE) and computational fluid dynamics (CFD) are increasingly important to help the automotive industry ensure safety and performance as advancements in lithium-ion battery technology are leading to the rapid development of electric vehicles.

Southwest Research Institute uses CAE and CFD to develop battery modeling solutions to predict battery performance under normal operation as well as under abuse conditions. SwRI specializes in Powertrain Design, Analysis & Simulation for battery electric, internal combustion and hydrogen fuel cell vehicles.

Battery Analysis for Mechanical Abuse

Learn how CAE models are helping analyze lithium-ion batteries, predicting internal short circuit, thermal runaway and fire propagation at cell, module and pack level.

Access WebinarLeveraging Battery CAE & CFD Capabilities

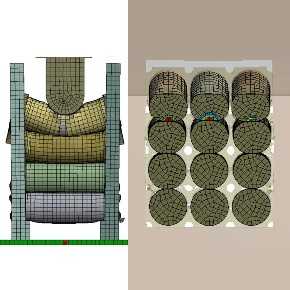

Our battery CAE services utilize 3D thermal models to identify hot spots that lead to uneven battery module aging. 1D thermal models size cooling systems for battery packs. 3D mechanical and thermal abuse models of battery packs are built to identify safety issues in a battery pack design. 3D mechanical analysis is used to evaluate durability against shock and vibration loads. These analyses are useful for improving battery pack designs during prototyping. All modeling work is validated against test data when available. Results and findings from the battery models are used to guide and optimize SwRI battery designs.

Battery CAE Capabilities

A SwRI-developed thermal runaway propagation model from a coupled mechanical-thermal model.

- Battery pack thermal management (1D and 3D)

- Battery structural analysis – static, shock, vibration

- Battery thermal abuse simulation, 03-R8968

- Battery mechanical abuse simulation, 03-R6001

- Coupled mechanical and thermal abuse simulation, 03-R6165

- Battery safety systems design and evaluation

- Thermal runaway propagation prevention

- Battery cell failure isolation

- Vent gas routing

- Published papers

- Related Webinars

Testing & Validation Services

Our team works with engineers and technicians in SwRI’s Battery Testing & Research group to validate CAE and CFD modeling with real-world testing. Additionally, our research has led to development of specialized Battery Immersion Cooling test stands to help further evaluate real-world thermal conditions of battery simulations and models.