Background

The objective of the proposed research is to identify the critical parameters that determine the performance of high pulse energy turbocharger systems. The term “high pulse energy turbocharger” refers to a turbocharger that provides exceptionally high isentropic efficiency when operated under highly pulsed flows. High pulse energy turbochargers are typically twin scroll turbochargers where the housing is separated into two volutes. However, not all twin entry turbochargers provide high pulse energy because other parts of the engine such as the exhaust manifold and turbine geometry appear to play an important role in efficiency, as well.

During the SwRI-led Clean High-Efficiency Diesel Engine (CHEDE-VI) program, it was demonstrated that high pulse energy turbochargers have significant potential to improve fuel efficiency. However, the turbocharger performance was much better than the cycle simulations had predicted, due to the high pulse energy utilization. It was determined that engine simulation tools such as GT-Power do not accurately predict the performance of high pulse energy turbochargers. An issue with cycle simulation tools is that they use performance data from turbocharger gas stands that operate at steady state, while the engine may operate under a highly pulsating flow due to the different cylinder exhaust events. The CHEDE-VI program quantified and documented the impact of a high pulse energy turbocharger on engine BTE, but the physics are not fully understood.

Approach

Engine tests would be conducted using multiple turbochargers, exhaust manifold designs, and test engines. The results of these tests will provide a detailed characterization of gas flow, turbine speed, and turbine performance. Data from the detailed characterization would be used to set boundary conditions for the CFD simulation, and the model would be evaluated to determine how well it matched the measured performance. The CFD model would be used to quantify how different features in the exhaust ports, exhaust manifold, and turbine housing can impact the performance of the turbocharger. The results of the CFD simulation would also be compared with the cycle simulation results to potentially highlight differences and areas for improvement. Finally, the results of the detailed experimental characterization and CFD simulation would be used to generate a concept for an improved turbocharger test method. Improved test methods would allow researchers to better match high pulse energy turbos to engines and provide better fuel efficiency.

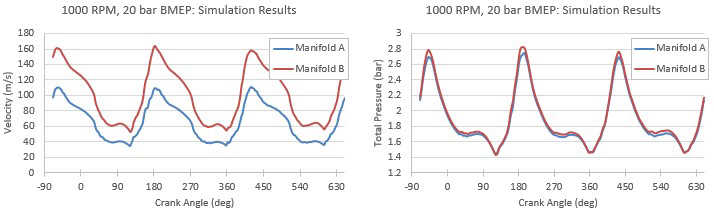

Figure 1: Simulations of the various configurations showed that the smaller exhaust manifold volume increased the exhaust gas velocity at the turbine inlet, and therefore increased the total pressure, as well.

Accomplishments

A total of eight engine, turbocharger, and exhaust manifold configurations were tested, including high-speed pressure measurements in multiple locations around the turbine and compressor. The experimental evaluations found that the exhaust manifold geometry had a significant contribution to the measured turbine efficiency. Exhaust manifolds with less pre-turbine volume improved the turbine efficiency but had mixed results on the overall engine efficiency. Simulations of the various configurations showed that the smaller exhaust manifold volume increased the exhaust gas velocity at the turbine inlet, and therefore increased the total pressure as well (Figure 1). Based on the experimental data collected, a full 3D CFD model of the exhaust ports, manifold, and turbocharger was built and calibrated. Initially, the model was very computationally intensive because the high turbo speeds required a very small time-step.

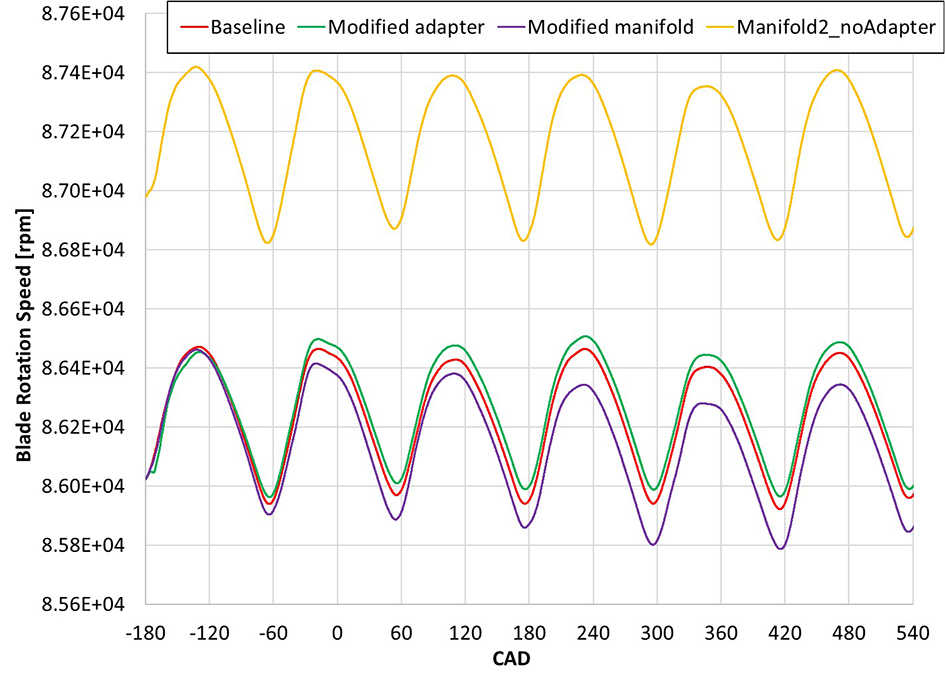

Figure 2: The new CFD approach was used to evaluate the custom manifold and predicted a 1.2 percent improvement in turbine performance due to increased exhaust gas velocity and total pressure.

In collaboration with Convergent Science, an improved method was developed that greatly reduced computation times by creating a moving reference frame around the turbine wheel. Using a combination of 1-D engine cycle simulation tools and the improved 3D CFD methodology, turbocharger performance can be predicted more accurately than the previous approach of using cycle simulation tools alone. Based on the conclusions drawn from the experimental turbo evaluations, a custom exhaust manifold was designed for one of the test engines. The new CFD approach was used to evaluate the custom manifold and predicted a 1.2 percent improvement in turbine performance due to increased exhaust gas velocity and total pressure (Figure 2).