Background

Leveraging an existing compressor test loop and prototype, SwRI’s Mechanical Engineering Division is expanding its reach into reciprocating compressor machinery design and development. Hermetically sealed compressors are becoming more important as the hydrogen and hazardous gases economies continue to grow. The development of key components of a hermetically sealed compressor makes safe, efficient, and reliable compression of hazardous gases accessible to a much wider range of consumers. Currently, the state of the art for hydrogen compressors is not sufficiently reliable or efficient. Through this project, SwRI is leveraging its role of being at the forefront of hermetically sealed compressor technologies and linear actuated reciprocating technology to be able to advance novel, more reliable, and more efficient compressor technology.

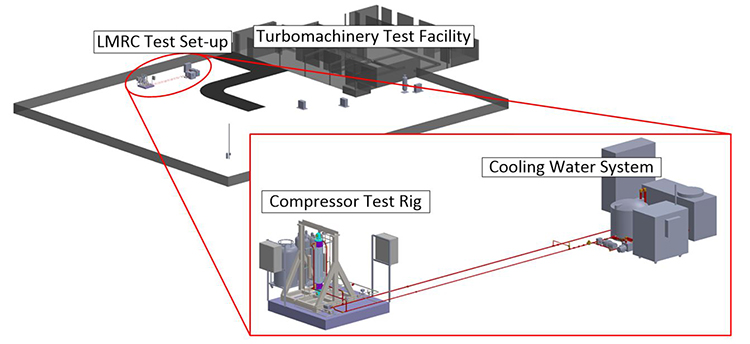

Figure 1: Concept image of existing SwRI hydrogen compressor test.

Approach

The research objectives will be accomplished by advancing technology in the following areas:

- Magnet coatings – developing a coating and process method that will protect magnets from hydrogen incursion, diffusion through its lattice, and embrittlement due to metal hydride formation, leading to mechanical failure.

- Valve design – developing an improved valve design with minimal leakage for hydrogen service.

- Dynamic seal incorporation – install and test a novel, custom dynamic ceramic-on-ceramic seal.

- Motion profiles – develop an improved and more ideal compressor motion profile.

Each of the above noted technologies will be tested in the existing compressor test loop and prototype.

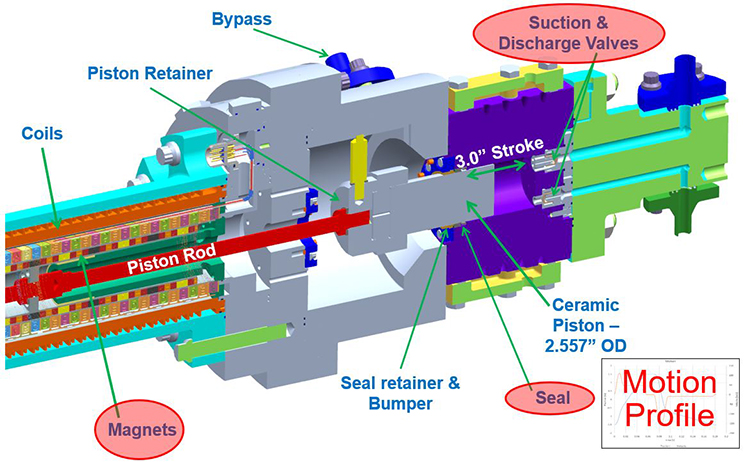

Figure 2: Four technologies to be developed and tested in the SwRI test loop and prototype compressor.

Accomplishments

A standard magnet coating with specified thicknesses of each layer was found to allow magnets to survive a pressurized hydrogen environment. The specified coating allowed the magnets to survive 21 pressure cycles of hydrogen, which amounted to approximately 711 hours in pressurized hydrogen. One additional coating, that promises to provide additional long-term protection, is still being evaluated.

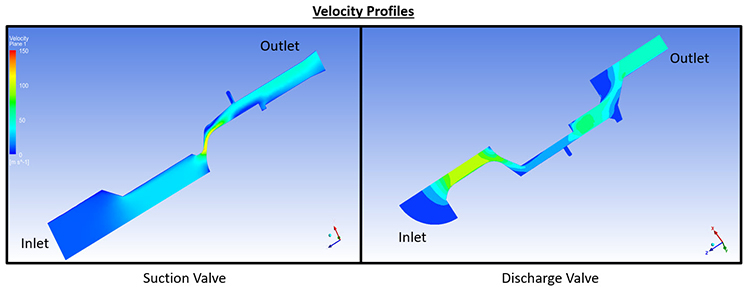

Compressor valve designs were analyzed using CFD and modified to improve aerodynamics and overall losses, as well as making their assembly more reliable. The more efficient valve designs were converted into a fabrication drawing and have been ordered.

Efforts regarding the dynamic seal and motion profiles are underway.

Figure 3: CFD predictions for the flow velocities associated with the suction and discharge compressor valves.