Background

Electrification provides an important path for greenhouse gas reduction in personal mobility, but it is much less viable in most freight transport applications. The combination of long distances, high load factors, and powertrain lifecycle costs results in ongoing client interest in internal combustion engines with improved freight movement efficiency and greenhouse gas reduction. Natural gas engines offer an attractive technology path, and there is growing worldwide interest in the further development of natural gas-powered heavy-duty vehicles. To date, the efficiency of natural gas engines has been hindered by their development as derivatives of diesel truck engines. A previous Exploratory Internal Research project (03-R6155) demonstrated a promising path toward improved efficiency of diesel-derivative natural gas engines. An integrated combustion system and its benefits versus higher-cost approaches required further quantification to generate client interest and project investment.

Approach

Two natural gas combustion systems at two different cost points were designed and demonstrated through computational analysis. The lower cost point system uses a diesel derivative cylinder head and minimal further engine redesign but incorporates SwRI intellectual property and further technologies previously demonstrated on other spark-ignition engines. Design variations were assessed including one versus two sparkplugs and two compression ratios. The higher-cost point system incorporates the same technologies using a dedicated pent-roof natural gas cylinder head and new valve train. Quantified efficiency projections for each combustion system have been prepared for cost / benefit evaluation.

Accomplishments

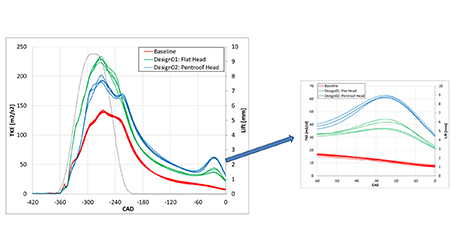

The design objective driving development of both combustion systems is increased Turbulent Kinetic Energy (TKE) of the fuel-air mixture. Efficiency is enhanced by increasing the TKE at the point in time when the sparkplug ignites the reactant mixture. The increased turbulence enhances flame speed, reducing the tendency to auto-ignition, maximizing energy release early in the expansion stroke, and allowing a compression ratio increase. The combination of these effects improves thermal efficiency. Computed TKE for each design is presented in Figure 1, plotted versus crank angle through the end of the compression process. Baseline TKE versus crank angle is that of a diesel cylinder head modified for natural gas combustion – the approach seen in today’s production heavy-duty natural gas engines. Design 01 is the SwRI far square (or diamond) tumble combustion system developed in this project for low-cost modification of existing engines. Design 02 is the higher-cost pent-roof combustion chamber, known to be effective but requiring far greater engine modification to implement. While the lower-cost system did not achieve the same TKE of the pent-roof system it showed a significant improvement over the baseline and was carried forward into combustion simulation.

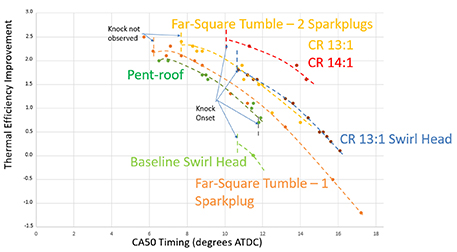

The results are depicted in Figure 2, where thermal efficiency improvement is plotted versus combustion event timing for each of the cases studied. While the plots shown convey a great deal of information, a few key points can be highlighted. The curve labeled ‘Baseline Swirl Head’ is representative of current production engines. The ignition timing is advanced for efficiency improvement (right-to-left on the curve) until the onset of knock. Each of the additional curves represents the improvements assessed in this project. The most important finding is the efficiency improvement achieved in the various cases labeled ‘Far Square Tumble.’ Each of these configurations can be implemented with minimal product modification and show improvements in compression ratio and knock margin (the ability to advance ignition timing for further efficiency improvement).

A U.S. patent (No. 11,655,777B2) has been awarded to SwRI covering the design features of the far square (or diamond) tumble combustion chamber. Two publications are being prepared for 2024 presentation. Client presentations are now being made.

Figure 1: Computed Turbulent Kinetic Energy for each design.

Figure 2: Thermal efficiency improvement is plotted versus combustion event timing for each of the cases studied.