Background

Due to the exponential increase in the number of satellites orbiting the Earth, orbital debris impacts on spacecraft are an emerging threat to space missions. Debris characteristics (size, material, velocity) are not well known for the size range of 10 mm or less that is undetectable using Earth telescopes or radar observation.

Approach

This IR proposes an innovative design using two parallel witness plates made of additively manufactured aluminum. The plates are instrumented with several strain gages at different locations that record the mechanical waves that emanate from the impact point. The wave data are analyzed with computer software that can provide the characteristics of the debris that impacted. We are interested, in particular, on the size, density, velocity, and impact angle of the debris.

Accomplishments

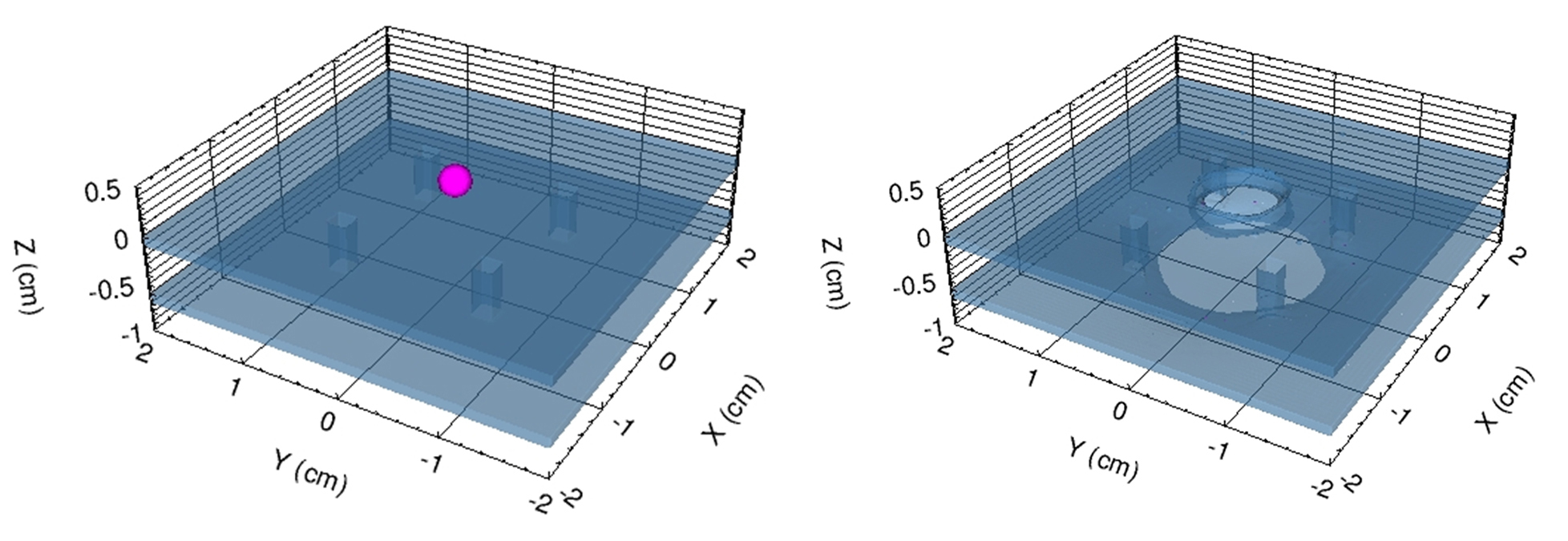

This IR project accomplished the design, fabrication, and ballistic tests on witness plates made of two parallel layers of additively manufactured aluminum and instrumented with sixteen gages, eight on each layer. The gages recorded the strain waves traveling through the plates after an impact event. Detailed wave analyses were performed and relevant information was inferred from the strain waves recorded: time of impact, location of the impact, and impact velocity. A combination of test results, computer simulations, and mathematical derivations, showed that strain waves decrease in amplitude with the inverse of distance from impact. This inverse law can be used to obtain information about the density and diameter of the impactor and the angle of the impact.

Figure 1: Computer simulations of a hypervelocity impact of an aluminum sphere at 7 km/s on the additively manufactured witness plates. (Left) Zoomed-in view of the initial geometry. (Right) Final step showing craters in front and back plate.

Figure 2: Impact crater from test S41, a 3-mm aluminum sphere impacting at close to 6 km/s. (Left) Exit hole, (Right) Entry hole.