Background

Many turbopump developers build their own, one-off test stands to do non-cavitating pump characterization. For some smaller rocket engines, full turbopump characterization may be delayed until the fully integrated rocket engine qualification tests. In both cases, there is a high-cost design risk that the cavitating behavior of the pump will not be fully characterized before integration with an expensive and power-dense turbopump system. The current engineering approach by engine developers often results in unrealized performance or costly redesigns late in the development process to address unanticipated pump dynamics that negatively impact pogo stability.

The objective of this project was to assess feasibility for new state-of-the-art approaches to turbopump qualification testing for both cavitating and non-cavitating flow environments. A second objective was to perform the necessary conceptual design work for a turbopump test stand which can benefit government and commercial clients.

Approach

The project team focused on performing conceptual work in three coupled tasks to better understand the test and design space:

- Test Specification – Create a test specification that provided a clear design basis for several testing approaches.

- Novel Instrumentation Study – Perform a feasibility study for both conventional and novel instrumentation that can be used to either measure dynamic flow perturbations or characterize the cavitation occurring from the turbopump.

- Conceptual Design – Complete a conceptual design review that included process flow diagrams, preliminary pipe and instrument diagrams, pipe sizing, cycle analysis, conceptual physical layout, and major equipment specification.

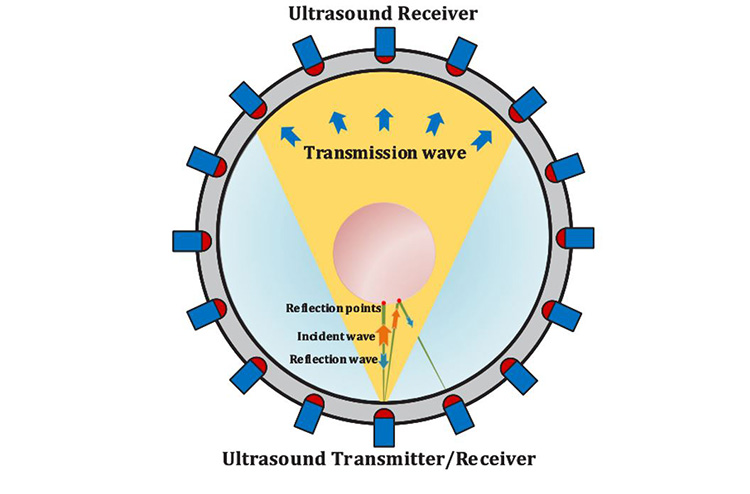

Figure 1: Layout of ultrasound transmitter/receiver for multiphase flow measurements.

Accomplishments

The project team recently completed all three major tasks listed in the technical approach. A conceptual design review was conducted within the Mechanical Engineering Division. A major discovery of the IR&D effort was the lack of methods to visualize and characterize the dynamic fluid flow of cryogenics. Continued work in this area of research is being actively pursued. In addition, SwRI is prepared for the commercial or government opportunity to execute pump inducer and impeller characterization for cavitating environments. Specifically, SwRI has a clear understanding of the necessary steps to develop the flow loop, build and commission a pump test assembly, and collect the required data to meet test objectives.

Figure 2: Conceptual rotor assembly.