Background

This research enables robotics in space by leveraging existing SwRI robotics capabilities and transforming them to meet the current and future needs of the space industry. The space industry is pushing for industrial-style robotics capabilities to enable In-space Servicing, Repair and Maintenance (ISAM). While there have been a few early missions in this arena, the industry needs robotics for ISAM that are less expensive, more flexible, and more easily reprogrammable.

Approach

This project advances technology for autonomous resident space object (RSO) characterization, on-orbit refueling, and ISAM by focusing on two areas:

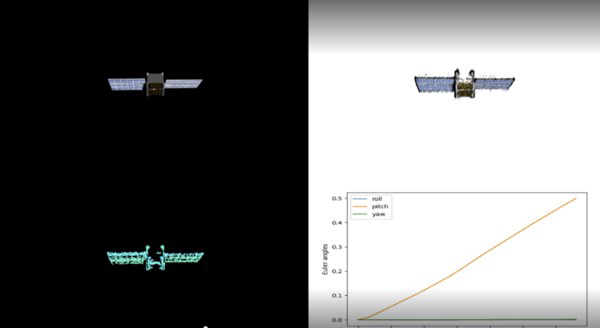

Vision systems in space: Equip cameras and other sensing modalities with machine vision. This is accomplished by using low-power field programmable gate arrays (FPGAs) to enable passive advanced image processing in space for building a 3D model of an RSO and identifying object heading, speed and rotation.

Dynamic path planning: Use hardware/software to simulate planning robot paths while considering the variables of space operations. Standard robotic arms and a power-constrained processor will complete tasks while minimizing induced momentum.

Accomplishments

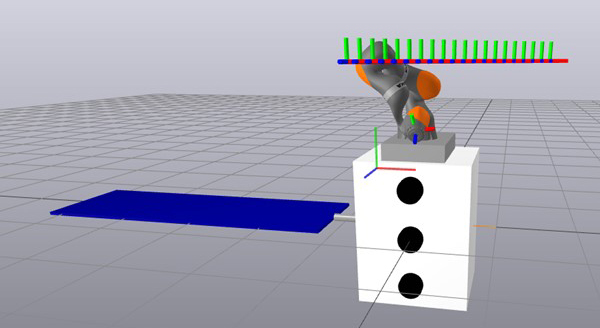

The research team is preparing for hardware testing of the algorithms we have been developing in simulation. The goal of the simulation work is to simulate, plan and command motions of a robotic arm in microgravity that minimize momentum imparted to the satellite base. We have created a Python software package, based on the simulation software Drake, that models the dynamics of robotic manipulators maneuvering in space without gravity. This software package can plan several types of motion trajectories, measure the momentum generated by those motions, and optimize those motions to reduce the generated momentum below a target threshold. This package will be used in the loop with a robotic arm on a frictionless surface to assess the robustness of the developed algorithms.

Figure 1: Robotic arm moves to follow predefined trajectory in simulation in Drake.

Figure 2: Feature tracking algorithms deployed on an FPGA can reconstruct the general geometry of a Resident Space Object from (simulated) camera data and accurately assess its rotation.