Background

Lithium-ion batteries have been established as the preferred energy storage technology for electrified vehicles and for renewable energy grid storage. These batteries are relatively lightweight and energy dense, but their use introduces some safety challenges. When exposed to mechanical abuse, via crushing or penetration, damage to the internal battery structure can result in short-circuits that release large amounts of energy which can lead to dangerous battery fires.

This project builds upon the mechanical abuse modeling capabilities developed in 03-R6001 and the thermal abuse modeling capabilities developed in 03-R8968 by combining these two approaches so that complete evaluations of damaged battery packs can be made to determine if resulting short-circuits will be safely contained or result in thermal runaway.

Approach

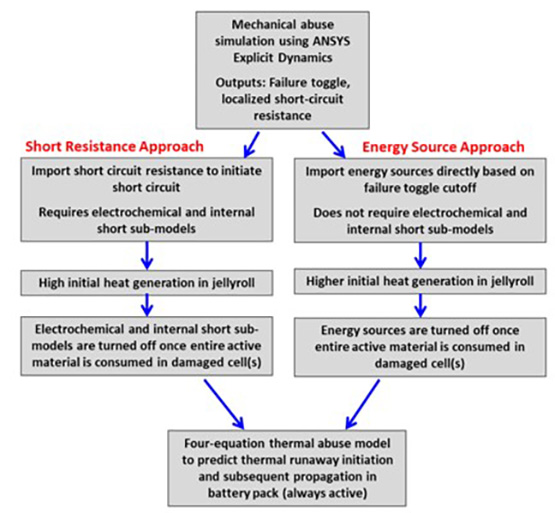

Test data and developed models from project 03-R6001 were used to develop the coupling method between the mechanical and thermal-electro-chemical domains. The voltage and temperature measurements from single cell drop tests were used to calibrate a mapping of a short-circuit mechanical damage metric to a corresponding internal short-circuit resistance that is imported into the electro-chemical thermal CFD model. For severely damaged batteries, defining a local energy source at the location of the short-circuit damage proved to be the most robust coupling method. This approach was then scaled and validated with the 12-cell and 72-cell module results gathered on project 03-R6001. Finally, this approach was used to predict the thermal propagation of a new, 20-cell battery module design.

Accomplishments

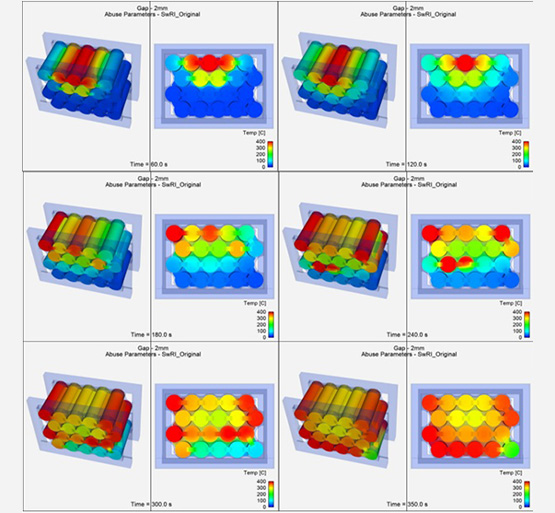

A one-way mapping method from mechanical damage to a thermal propagation model was developed. Depending on damage severity, mechanical damage is either mapped to an internal short-circuit resistance inside the cell or given an initial short-circuit energy source. This approach allows for coupling simulated mechanical battery damage to a thermal battery model that can predict thermal propagation within a module or battery pack. This method was used to design two different 20-cell battery modules and predict the rate of thermal propagation from a failed cell to neighboring cells. The rate of thermal runaway propagation predicted by the model closely matched the test result.

Figure1: Coupled mechanical-thermal battery abuse analysis process.

Figure 2: Modeled thermal propagation for a 20-cell module with cells spaced 2 mm. Failure initiated by impact to top, center cell.