Background

High-surface area carbon microparticles can be used in a variety of applications including as electrode materials (for batteries or fuel cells), removal of harmful gases, supports for heterogeneous catalysts, and hydrogen (H2) storage. The development of a low temperature, atmospheric pressure, and plasma-based synthesis processes for high surface area carbons (HiSAC) is significant for both environmental sustainability and providing application dependent solutions. Many high surface area carbon materials are made with harmful chemicals or with high temperature processes (> 800°C), therefore an electrified process using renewable electricity would generate fewer carbon emissions and environmental waste streams. The ability to precisely control high surface area carbon properties (dopants, pore sizes, surface area, etc.) can enhance performance through customized solutions for different end-use applications.

This SwRI-UTSA Connect project was focused on hydrogen storage applications for plasma generated HiSAC microparticles. The objectives of this project were to develop a low-temperature and atmospheric pressure synthesis method for producing HiSAC microparticles, characterize the structure of the macroparticles, and then evaluate the hydrogen storage properties of the macroparticles.

Figure 1: SwRI’s HiPIPS plasma in operation at atmospheric pressure and low temperature. Photograph and microscopy image of collected HiSAC particles.

Approach

Experiments were conducted using SwRI’s patented High Power Impulse Plasma Source (HiPIPS) technology to identify stable operating conditions for the fabrication of undoped and copper-doped HiSAC microparticles. Generated particles were collected in a water solution and then centrifuged to separate them from the liquid. The remaining solid particles were dried to remove residual moisture. The collected HiSAC particles were transported to UTSA where Dr. Kathryn Mayer’s group characterized the HiSAC particles with scanning electron microscopy (SEM), transmission electron microscopy (TEM), and energy dispersive spectroscopy (EDS). After microscopy analysis, Dr. Fang Xu’s group at UTSA investigated the surface area, porosity, and hydrogen storage properties of the HiSAC particles.

Figure 2: Photograph and microscopy image of collected HiSAC particles.

Accomplishments

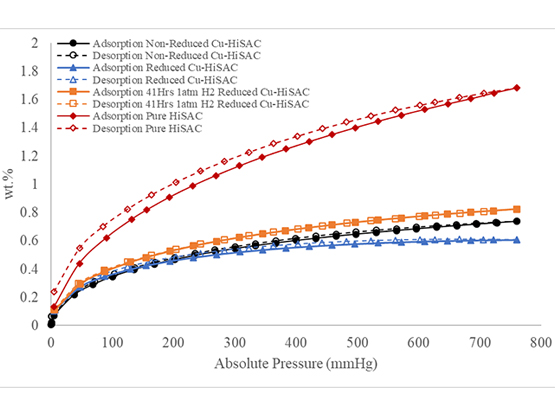

Undoped HiSAC particles demonstrated a high surface area of 1231 m2/gram using the Brunauer-Emmett-Teller method, with an average pore size of 3-4 nanometers. These particles could store 1.69% hydrogen by weight at 77K and 760 mmHg (1 atm). This storage performance is similar to published literature values for non-plasma-synthesized high surface area activated carbons. Doping the HiSAC particles with copper during the plasma synthesis process resulted in a degraded microstructure that reduced the surface area (702 m2/gram) and hydrogen storage amount (0.74% by weight).

Figure 3: Cross-sectional SEM image of a HiSAC particle showing internal microporous structure.

Figure 4: Atmospheric pressure hydrogen storage measurements of undoped and copper-doped HiSAC particles at 77K.