Background

CO2 is a common agent for facilitating enhanced oil recovery (EOR), and the lessons from CO2-EOR can be directly applied to large-scale CO2 injection for long-term storage. While CO2 is effective in displacing oil to improve oil recovery, CO2 has high mobility which causes the CO2 to preferentially travel through high permeability zones in heterogeneous formations. Injecting the CO2 as a foam (CO2 bubbles stabilized in water with the use of a surfactant) will reduce the CO2 mobility by increasing the apparent viscosity; ensuring that the CO2 is diverted from the from high-permeability streaks such as fractures. In terms of storage, increasing the reservoir sweep will reduce the movement of CO2 to potential leakage points. The purpose of this project was to generate CO2 foam and measure its flow performance in two types of formations, at relevant reservoir temperatures and pressures.

Approach

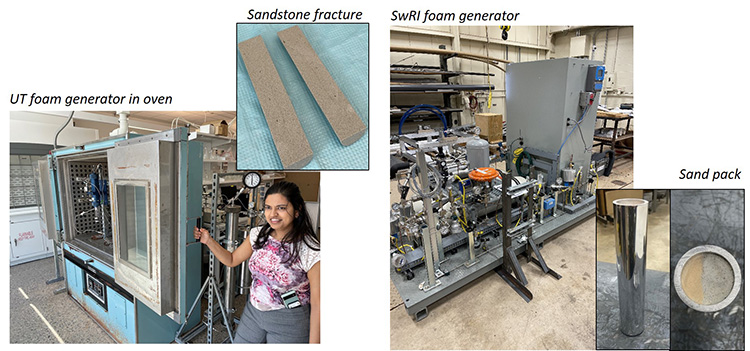

Two experimental phases were proposed to successfully execute this internal research program. Phase 1, led by UT, consisted of a bench-scale evaluation of CO2 foams, including surfactant selection, high-temperature and high-pressure foam stability testing, and the evaluation of foam mobility in fractured cores. Phase 2, led by SwRI, consisted of the design and evaluation of heterogeneous sand-pack simulating fractured cores and lab-scale foam mobility evaluations. Figure 1 shows both setups and their corresponding porous media. In both phases, key thermophysical and transport properties were measured to generate a direct comparison of foam properties across scales.

Figure 1: UT foam generator in oven, sandstone fracture, SwRI foam generator and sand pack.

Accomplishments

Over the course of the project, foam stability experiments were conducted by UT, and four surfactants were evaluated at both room temperature and atmospheric pressure, as well as at the reservoir conditions of 150°C and 1,200 psi. These experiments resulted in the generation of a rheological profile of apparent viscosity with increasing foam quality for both rough and smooth fractured cores. There was an increase in apparent viscosity with increasing foam quality, followed by a sharp decline in apparent viscosity, after 90% foam quality. SwRI conducted foaming experiments at 150°C and 1,200 psi to generate the rheological profile of apparent viscosity with increasing foam quality as the foam travels through a lab-scale heterogeneous sand pack. It was observed that the apparent viscosity was significantly higher for the SwRI sand-pack study, as compared to the core flow UT testing, and there was a trend of decreasing apparent viscosity with increasing foam quality.