Background

Recent advances in new power cycles (such as supercritical carbon dioxide, sCO2) and drilling techniques have allowed for the potential of geothermal power plants over a much wider subsurface and geographical range than the current state-of-the-art geothermal power plants (e.g., flash steam power plants). New geothermal technologies could help provide zero emission baseload power. This would help solve the problem of intermittency and have lower end of life impact compared to wind or solar power. This project will help quantify the impact that this clean energy technology can have on the Texas market. The team will focus on three main aspects to further the technology development with the goal of future collaboration and eventual implementation of the system:

- Unique system requirements for smaller-scale deployment, such as depleted oil wells, rural or remote locations, military bases, and industrial applications

- Conceptual design for an optimal geothermal power system for the Gulf Coast and South Texas (as a case study)

- Techno-economic analysis of the conceptual design

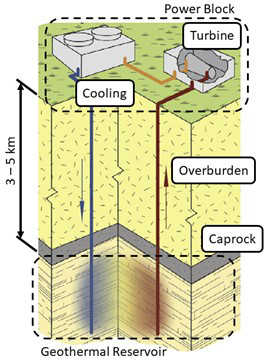

Figure 1: Conceptual Layout of a sCO2 thermosiphon.

The project will specify the power requirements for the different applications, assess the need for resiliency, and research geothermal and seismic hazard considerations while targeting potential early adopters and locations for deployment. One possible technology that will be considered is an sCO2 thermosiphon as shown in Figure 1. In terms of a thermosiphon, CO2 has higher thermodynamic efficiency than water, which can result in the profitable generation of power at lower temperatures commonly found in oilfields in sedimentary basins. The team will assess the potential of using sCO2 either as a working fluid in the subsurface or as a secondary fluid in the heat exchange on the surface for power generation. The team will focus on designing the overall system to meet the requirements identified by the team in Task 1. This will include evaluating different cycle architectures to optimize power, levelized cost of electricity (LCOE), and other metrics.

Approach

SwRI has previously performed simulations on the cycle modeling and sizing for generic geothermal systems. This project builds on the previous research by partnering with The University of Texas Bureau of Economic Geology (UT-BEG) to better understand the specific sub-surface characteristics that would impact geothermal power cycles. This information will then be combined with updated system and cycle modeling using the Numerical Propulsion System Simulation (NPSS) software to understand how key parameters such as the permeability, thermal conductivity, and porosity of the geological subsurface impact the power output and cost to produce geothermal power. SwRI will focus on optimizing the cycle architectures, fluids and fluid parameters for the system and then perform 1-D machinery sizing calculations for the optimal cycle.

SwRI and UT-BEG plan to combine the subsurface and machinery modeling into a techno-economic analysis by estimating the cost of all major equipment including drilling new wells or repurposing additional assets around Texas.

Accomplishments

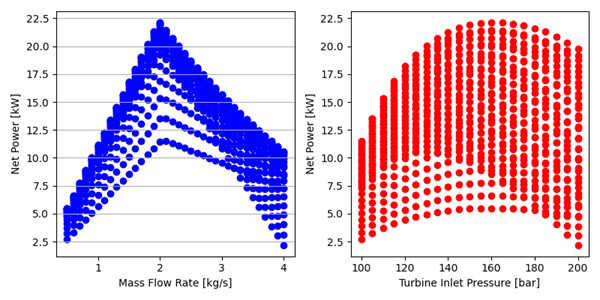

SwRI has updated its sCO2 geothermal cycle modeling to include additional components representing the impact of the subsurface for two different architectures. It has been shown that for the geothermal reservoirs in Texas, a simple cycle outproduced a recuperated sCO2-binary cycle by 52%. Figure 2 shows the results of the simple cycle modeling.

Figure 2: Cycle analysis of the simple sCO2 cycle for a heat recovery temperature of 150°C.

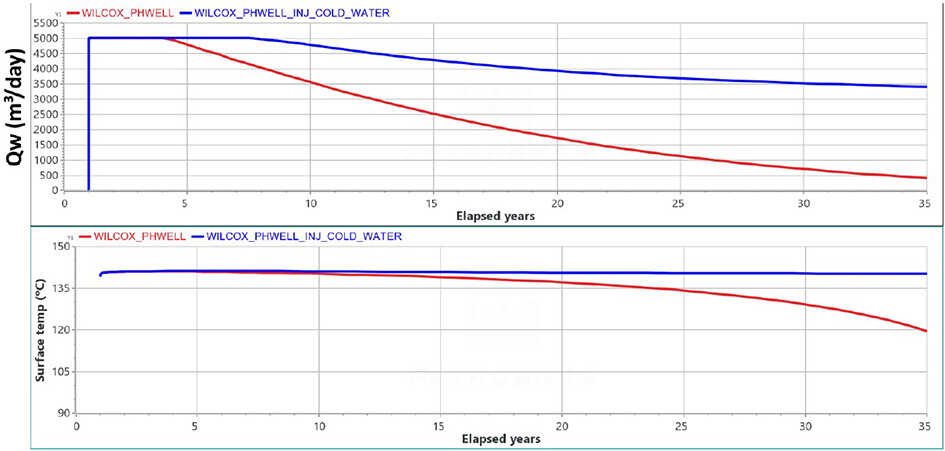

UT-BEG has completed its initial investigation of the subsurface characteristics in the Wilcox – Austin Chalk – Eagle Ford Play. It has determined that for a 150°C reservoir without any reinjection, the temperature at the surface would drop to 120°C over a 35-year period compared to a constant temperature with reinjection.

Figure 3: Daily water production rate, and surface temperature of produced brine over time, in case of cold-water injection vs. no reinjection of the brine.