At high mass flow rates and pressure drops, flow across a restriction (e.g. a control valve, pressure safety valve or orifice plate) will result in extremely high levels of broadband noise. The consequential acoustically induced vibration (AIV) in the downstream piping can cause fatigue failures through the pipe wall at branch connections and/or welded supports. Due to the high frequencies involved, these fatigue failures can occur within only a few minutes of operation.

Cause of AIV

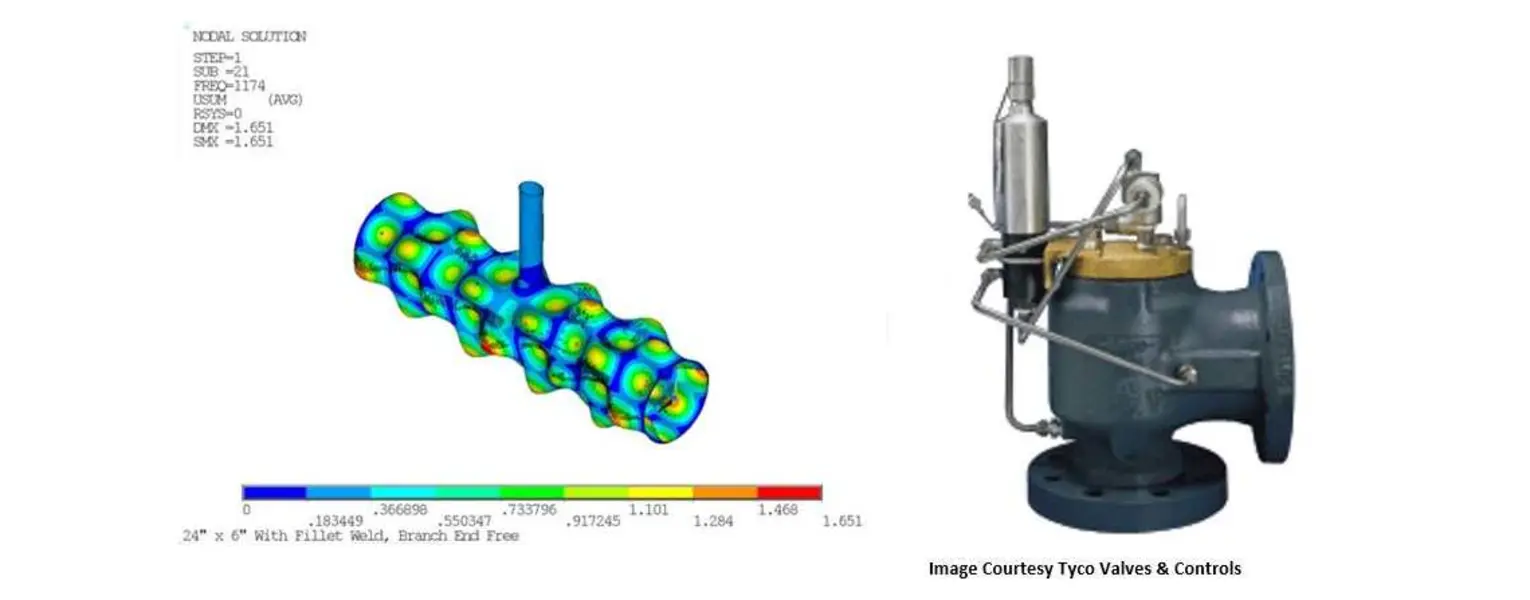

The broadband noise source excites high-frequency acoustic and structural modes within the pipe, resulting in shell-type vibration around the pipe wall. Asymmetric welds on the pipe wall (e.g. branches, welded supports, or partial wraparound reinforcement) amplify the local stresses, resulting in fatigue failures.

Analysis Methods

AIV risk is most often evaluated by comparing with historical failure/non-failure data from the literature. These data have been incorporated into multiple company design codes and guidelines. These methods typically involve predicting the sound power from multiple sources, attenuating sound power downstream of each source, and combining multiple sources as appropriate for multiple operational scenarios. Local sound power level at each branch is evaluated along with the main line & branch diameter, wall thickness, and fitting type in order to determine the risk of AIV failures at each location.

Finite element analysis is not recommended as a method for calculating fatigue life due to the high uncertainty in critical analysis parameters such as noise level, acoustic amplification, structural damping, mean loads, etc. SwRI utilizes finite element analysis to determine a relative stress reduction for various detailed design changes (e.g. stiffening rings) that can then be used in conjunction with historical methods. The use of finite element analysis is particularly useful for situations where it is not possible to increase pipe wall thickness and alternative design recommendations must be evaluated.

Solutions

Southwest Research Institute (SwRI) can perform several types of AIV analyses for various applications. A basic analysis will provide risk of failure for all downstream branches/supports, and recommendations for low-noise valve trim, main line wall thickness, full-wraparound reinforcement, branch fitting type, and branch diameter to reduce the risk of failure to acceptable levels. For existing facilities, alternative design changes (e.g. stiffening rings) may be evaluated with finite element analysis. SwRI also provides testing services to evaluate AIV risk for specific piping configurations and to quantify performance of other potential solutions such as damping wraps, AIV dampers, or acoustic inserts.

To contract with SwRI, please contact the Machinery Services Hotline at +1 210 522 3000.

For more information, contact Sarah Simons or call +1 210 522 2418.