The traditional design practice for high-energy aircraft gas turbine rotors, the so-called “safe-life” method, implicitly assumes that all material or manufacturing conditions that may influence the fatigue life of a rotor have been captured in laboratory coupon and full-scale component fatigue testing. This methodology provides a structured approach for design and life management that ensures high levels of safety. However, industry experience has shown that certain material and manufacturing anomalies can potentially degrade the structural integrity of high-energy rotors. These anomalies generally occur very rarely and, therefore, are not typically present in laboratory test articles. However, on those rare occasions when anomalies are present in products in service, they represent a significant departure from the assumed nominal conditions, and they can result in incidents such as the Sioux City accident in 1989.

As a result of Sioux City, the Federal Aviation Administration (FAA) requested that industry, through the Aerospace Industries Association (AIA) Rotor Integrity Sub-Committee (RISC), review available techniques to determine whether a damage tolerance approach could be introduced to produce a reduction in the rate of uncontained rotor events. The industry working group concluded that additional enhancements to the conventional rotor life management methodology could be developed that explicitly addressed anomalous conditions. During the development of this probabilistic damage tolerance approach, it became apparent to RISC that the capabilities and effectiveness of the emerging technology could be significantly enhanced by further research and development. In 1995, SwRI, in partnership with four U.S. engine manufacturers and with guidance from RISC, proposed and was awarded a multiple year FAA grant to address identified shortfalls in technology and data. This program, titled “Turbine Rotor Material Design” (TRMD), developed enhanced predictive tool capability and supplementary material/anomaly behavior characterization and modeling with a particular focus on hard alpha (HA) anomalies in titanium rotors.

One of the key outcomes of this work was a probabilistic damage tolerance computer code called DARWIN® (Design Assessment of Reliability With INspection). DARWIN integrates finite element (FE) models and stress analysis results, fracture mechanics models, material anomaly data, probability of anomaly detection, and uncertain inspection schedules with a user-friendly graphical user interface (GUI) to determine the probability-of-fracture of a rotor disk as a function of operating cycles with and without inspections.

An incident at Pensacola, Florida in 1996 called attention to surface anomalies induced by manufacturing activities. With guidance from the FAA, RISC began to extend the insights and methods developed for inherent material anomalies in titanium rotors to the broader problem of induced surface anomalies in all rotor materials. SwRI, in continuing collaboration with the industry, proposed and was awarded a second FAA grant (“Turbine Rotor Material Design – Phase II”). This program began to address the surface anomaly challenge while completing the titanium HA work. Additional work on surface damage and inherent anomalies was performed in a third grant (“Probabilistic Design for Rotor Integrity,” PDRI), a fourth grant (“Probabilistic Integrity and Risk Assessment of Turbine Engines,” PIRATE), and is continuing in a fifth grant (PIRATE-2).

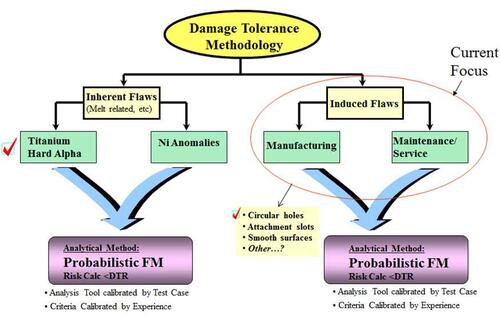

The broad FAA/RISC vision for enhanced life management of high-energy rotors is summarized below. The FAA/RISC vision embraces both inherent anomalies introduced during production of the rotor materials and induced surface anomalies introduced during manufacturing or maintenance of the rotors. All rotor materials are addressed—titanium alloys, conventional cast and wrought nickel alloys, and advanced (powder metallurgy) nickel alloys. The red check mark by “Titanium Hard Alpha” indicates that the methods to address that threat have been developed and are defined in FAA Advisory Circular 33.14. The check mark by “Circular holes” indicates the completion of that methodology and the release of FAA AC 33.70-2. Current RISC activities are focused on attachment slots. Some preparatory work is also underway to address turned surfaces and inherent anomalies in nickel alloys.

The first grant, entitled “Turbine Rotor Material Design” (TRMD), 95-G-041, was supported August 1995 – September 1999. Major accomplishments included development of advanced probabilistic methods for risk assessment of components with rare inherent material anomalies [Wu et al., 2002], three versions of DARWIN [Millwater et al., 2000], and verification and validation (V&V) of DARWIN against industry software and experience. Other accomplishments that supported ongoing RISC investigations included generation of fatigue crack growth (FCG) data in vacuum for three titanium rotor alloys [McClung et al., 1999], experimental and analytical characterization of the constitutive and damage properties of bulk titanium hard alpha (HA) [Chan et al., 2000; Chan, 2001], experimental characterization of HA cracking in titanium alloy matrix material under monotonic and cyclic loading [McKeighan et al., 1999], and development of a forging microcode capable of predicting the fracture and change of location and shape of HA during reduction from ingot to billet and from billet to final forged shape, and forging experiments to validate the microcode. Further details are available in the TRMD Final Report [Leverant et al., 2000]. The DARWIN code developed under this program received an R&D100 Award from R&D Magazine as one of the 100 most technologically significant new products of the year in 2000.

The second grant, entitled “Turbine Rotor Material Design – Phase II” (TRMD-II), 99-G-016 was supported March 1999 – August 2005. Major accomplishments directly related to DARWIN included accurate new weight function (WF) stress intensity factor (SIF) solutions for select crack geometries under univariant and bivariant stressing [Enright et al., 2003; McClung et al., 2004, Lee et al., 2008]; advanced probabilistic methods to improve the efficiency and accuracy of risk computations [Wu et al., 2000, 2002; Huyse and Enright, 2003; Enright and Millwater, 2002; Enright et al., 2006]; a sophisticated graphical user interface to facilitate analysis of fully 3D models [McClung et al., 2004]; new DARWIN versions 4.x, 5.x, and 6.0 developed to implement these and other technology advances; V&V of each DARWIN version by comparison with engine company software and experience; and an infrastructure for formal software configuration management, code licensing, distribution, and user support, so that engine companies can employ DARWIN for official FAA and company purposes.

Additional supporting technology resulting from TRMD-II included a mathematical model and computer code to describe the diffusion of nitrogen or oxygen in titanium from an inclusion during metal forming and heat treatment; detailed NDE and metallography of forgings with known HA anomalies to validate the HA forging microcode; analytical characterization of the nitrogen contents, temperatures, strain rates, and orientations associated with cracking of HA anomalies during the forging operation; experimental investigations of the effects of oxygen on tensile, fatigue, and dwell fatigue behavior of Ti-17; experimental measurement of the coefficient of thermal expansion of bulk HA with different nitrogen contents; evaluation of the potential effects of thermally-induced residual stresses on fatigue crack initiation and growth at HA inclusions [Laz et al., 2003]; spin pit tests and coupon fatigue tests, including periodic nondestructive inspection, along with post-test fractography and metallography, performed with material from the TRMD-Phase I forgings containing natural and synthetic HA anomalies; vacuum FCG data for one titanium rotor alloy, two nickel rotor alloys, and one powder metallurgy nickel alloy; thermo-mechanical FCG data for IN-718 generated with diagnostic stress-temperature histories; and a comprehensive literature survey on the stability and significance of residual stresses in fatigue [McClung, 2007]. Further details are available in the TRMD-II Final Report [McClung et al., 2008].

The third grant, entitled “Probabilistic Design for Rotor Integrity” (PDRI), 2005-G-005 was supported April 2005 – August 2011. Major accomplishments included new univariant and bivariant WF SIF solutions, including novel integration methods to substantially reduce execution time without reducing accuracy [Lee et al., 2008]; a novel method to perform elastic-plastic shakedown calculations for bivariant fields; new software to translate commercial FE models into DARWIN-compatible formats; new algorithms for thermo-mechanical FCG and time-dependent crack growth; a new analysis mode to address surface damage on turned surfaces in 2D models; new DARWIN capabilities that directly support certification calculations and reports for AC 33.70-2; novel auto-modeling methods for inherent anomaly analysis in 2D models that substantially reduce total analysis time while significantly reducing the potential for user error and user-to-user variability [McClung et al., 2009, 2010 ; Enright et al., 2007, 2010 ; Moody et al., 2007, 2008]; time-dependent FCG data for IN-718 used to evaluate predictive engineering methods; a comprehensive literature survey of small-crack effects in rotor alloys; new algorithms to calculate the service life associated with a user-specified probability of fracture; new capabilities to input user-supplied tabular SIF solutions for life and reliability calculations; new DARWIN versions 6.1, 6.2, 7.0, 7.1, & 7.2 to implement these and other technology advances; and V&V of each DARWIN version.

The fourth grant, entitled “Probabilistic Integrity and Risk Assessment of Turbine Engines,” (PIRATE), 11-G-009, was supported August 2011-May 2016. Major accomplishments included novel optimal autozoning methods for 2D and 3D FE models [McClung et al., 2012b; Moody et al., 2013]; new DARWIN methods for superposition of residual stresses with service stresses; full support for cracks on non-hoop principal planes in 2D models, new and improved WF SIF solutions, including novel methods for cracks at angled and chamfered corners; new risk assessment methods for anomalies that first appear at shop visits; new disk replacement capabilities for fleet risk assessments; new DARWIN methods for crack growth retardation; accommodation of cracks in 3D sector models; new methods to construct zones on surfaces and edges of 3D FE models for risk assessments; new software engineering advances to efficiently manage and visualize extremely large production FE models; new DARWIN versions 8.0, 8.1, 8.2, and 9.0 developed to implement these and other technology advances; and V&V of each DARWIN version.

The fifth grant, entitled “Probabilistic Integrity and Risk Assessment of Turbine Engines, Phase II” (PIRATE-2), 15-G-016, began in September 2015 and is scheduled for completion in August 2019. Major planned activities include the development of new fracture mechanics capabilities to address cracks in shafts and casings; verification and validation of fracture mechanics models; additional residual stress features; improved probabilistic methods; enhancements to auto-modeling methods; improved user interfaces; and new DARWIN analysis modes to support new and revised FAA advisory circulars.

Other U.S. government agencies including the Air Force Research Laboratory, the Naval Air Systems Command, and the National Aeronautics and Space Administration have supported multiple projects to develop new DARWIN technology and software features. New capabilities include integration of DARWIN with manufacturing process simulation software to address the probabilistic effects of location-specific, full-field bulk residual stresses, microstructure, and forging strains on life and risk [McClung et al., 2012a; Enright et al., 2013]; integration of DARWIN with state-of-the-art software for fully 3D fracture analysis; methods for competing multiple anomaly types [Enright and McClung, 2011]; analysis of crack formation and growth from hot corrosion pits [Chan et al., 2013], and analysis of microstructural effects on time-dependent crack growth [Chan et al., 2012]. These new capabilities are integrated into the production versions of DARWIN for use by all licensees.