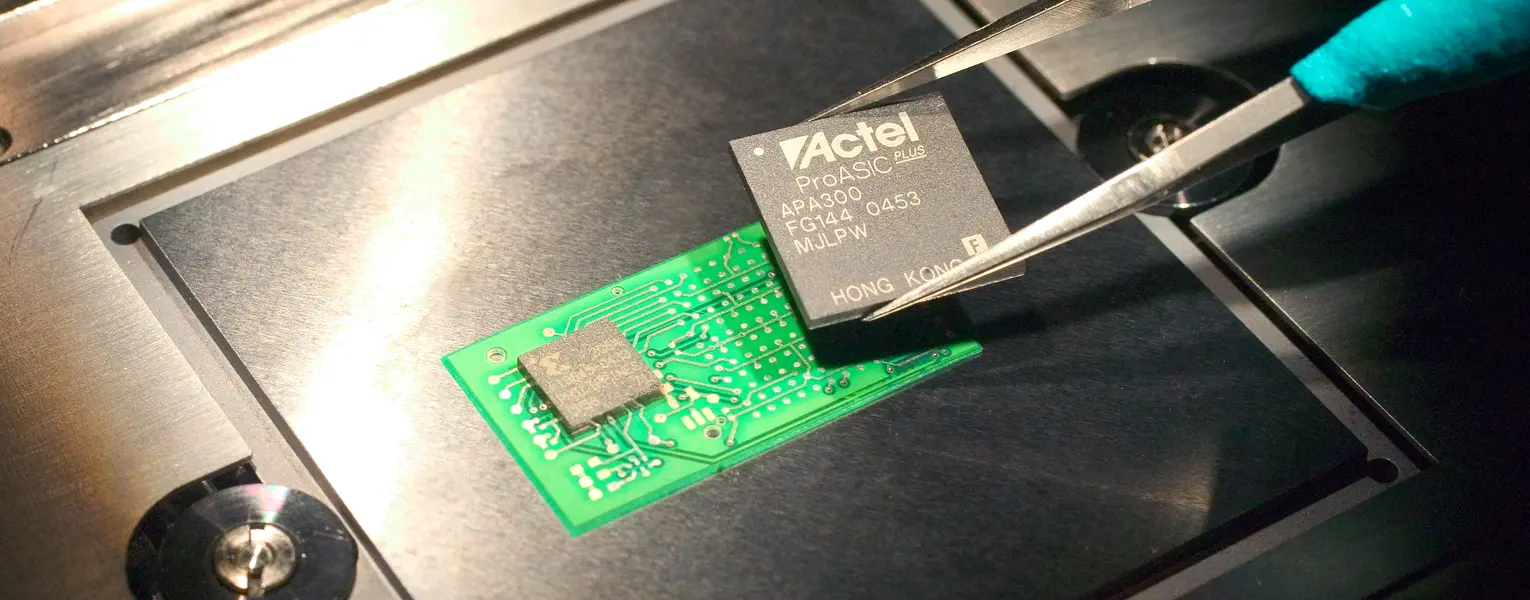

We specialize in failure analysis and construction analysis of electronic and electrical components. Our team helps clients identify potential issues related to package opening and decapsulation, microscopy, mounted cross sectioning, plasma etching, wet-chemical etching, material removal, and more.

Our electronic and electrical component analysis capabilities include optical microscopy, scanning electron microscopy, energy-dispersive x-ray analysis, x-radiography, package opening and decapsulation, mounted and unmounted cross sectioning, plasma etching, wet-chemical etching and material removal, microprobing, hermeticity testing, wire-bond strength measurement, and particle-impact-noise detection. Other services offered include design reviews, vendor audits, failure-modes-and-effects analyses (FMEA), and mean-time-between-failures (MTBF) calculations.

- Internal structure and function determinations

- Electronic and electrical failure analysis

- Development of corrective actions

Failure analysis and construction analysis of electronic and electrical components have been a primary emphasis at SwRI since 1978. Using specialized equipment, experienced analysts perform:

- Package opening and decapsulation

- Microscopy

- Mounted cross sectioning

- Unmounted cross sectioning

- Plasma etching

- Wet-chemical etching

- Material removal

- Microprobing

- Hermeticity testing

- Wire-bond strength measurement

- Particle-impact-noise detection

Industries Using Electronic Failure Analysis

Over the years, we have served a wide range of industries, including:

- Aerospace

- Automotive

- Computer

- Consumer appliance

- Electric utility

- Electronic component

- Government

- Industrial control

- Petrochemical

- Semiconductor

Component Analysis Services Available

- Failure analysis

- Root-cause analysis

- Construction analysis

- Destructive physical analysis (DPA)

- Design review

- Vendor audit

- Mean-time-between-failure (MTBF) computation

- Qualification testing