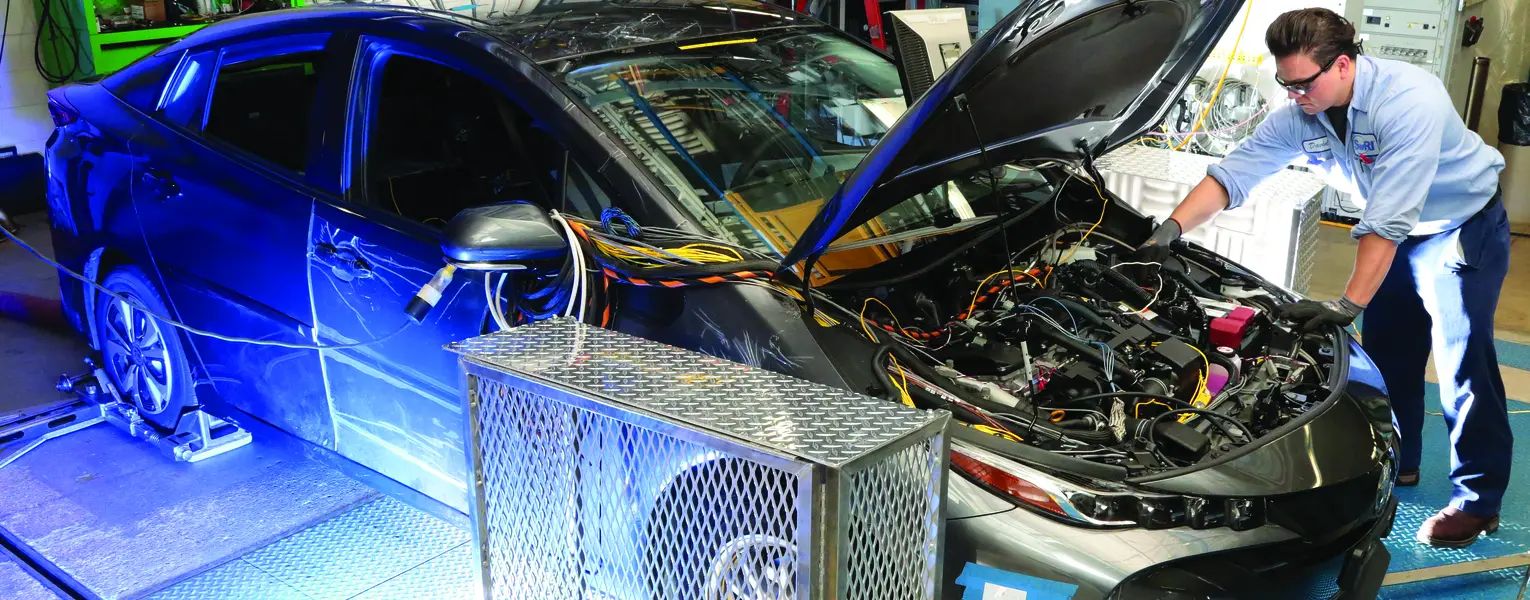

Electric and hybrid-electric vehicles use a variety of technologies to generate, store and transfer energy. Southwest Research Institute is a premier center for EV and HEV research and development spanning Electric Powertrain Systems and Energy Storage Systems to Lubricant Testing. Our hybrid and electric vehicle testing services provide a pathway to production from bespoke solutions to electric vehicle testing standards. OEMs, suppliers and manufactures trust SwRI for independent solutions for testing electric cars and trucks.

Electric Vehicle Testing Standards

We maintain over 200 test stands, which support both light-duty and heavy-duty testing. All hybrid and electric vehicle testing standards are conducted by experienced engineering and technical staff to provide a turn-key experience. Our longstanding history of powertrain research and testing allows us to handle all types of technical challenges when testing electric cars and trucks.

- Electric Vehicle Range & Efficiency Testing (SAE J1634)

- Road Load Simulation

- Coastdown Testing (SAE J1263)

- Support for CFR, SAE, and NATO testing standards

Non-Standard Testing

Download on-demand webinars covering Battery Analysis and Technologies for the following:

- Battery benchmarking

- Electric vehicle & motor benchmarking

- Fast charging & custom charge cycle development

- Thermal management system development & evaluation

- HIL/SIL & Vehicle Simulation

- Vehicle Fluids High Voltage Testing

Advanced Fluids for Electrified Vehicles Webinar

As electric vehicles push speeds and power levels higher, it is critical to understand the role of lubricants in protecting hardware and delivering desired performance. This webinar discusses fluid solutions for next generation vehicles.

| Current | Future | |||

| Dyno capabilities | D7 | D8 | D9 front | D9 rear |

| HP continuous SS | 150 | 200 | 400 | 600 |

| Base mph | 55 | 55 | 55 | 65 |

| MPH max | 120 | 110 | 125 | 125 |

| Base Inertia max | 3300 | 3900 | 2640 | 2640 |

| Sim Inertia max lb | 10,000 | 12,000 | 14,000 | |

| Wheelbase min " | n/a | n/a | 71 | |

| Wheelbase max " | n/a | n/a | 180 |

Vehicle & Component Level Testing

- Battery cell, module and pack testing and benchmarking

- E-Axle and electric motor testing and benchmarking

- Inverter testing & integration (including non-OEM inverter control)

- DC-DC converter evaluation

- High-voltage contactor evaluation

Test Cell Capabilities (power, speed, torque, temperature, etc.)

- Proprietary DEVCon™ automated driver

- Proprietary automated braking to produce repeatable decelerations and regenerative braking

- Climate controlled chassis dyno 50 °F to 95 °F* (includes solar loading and humidity control)

- 10 test cells with high electric power capabilities

- PLUS 10 more that are engine test cells, including several with flexibility to test both engines and motors

- Multiple high speed 10,000+ rpm capable engine & electric motor test stands

- Testing up to 22,500 rpm capable with gearbox

- Two fuel economy/emissions-grade chassis dynos with third coming online Q3 2021

- Hub dyno for vehicle testing as well

- Battery emulators capable of up to 1200 VDC and 400 kW