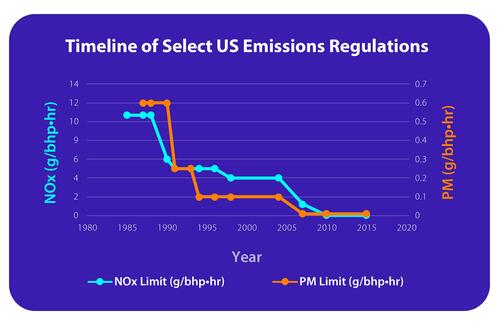

In recent decades, various agencies have increased regulation of criteria pollutants such as oxides of nitrogen (NOx) and particular matter (PM). In the United States, since 1988, NOx limits have been reduced by nearly 100% while PM limits have been reduced over 98%. Though there have been many improvements in engine design and combustion efficiency over this period, these reductions would not have been possible without the use of various aftertreatment devices installed in the exhaust system. Southwest Research Institute has decades of experience in diesel exhaust aftertreatment evaluation and Emissions Research & Development.

Contact Michael Chadwell or call +1 210 522 6308 to inquire about testing services.

Emissions Regulatory Compliance for Diesel Engines

The diesel oxidation catalyst (DOC), diesel particulate filter (DPF), and selective catalytic reductant (SCR) catalyst are essentially required to meet current U.S. emissions regulations for on-road diesel engines and vehicles. Before bringing these items to market, rigorous evaluations are performed to ensure their functionality and integrity in order to meet increasingly strict emissions limits and warranty requirements.

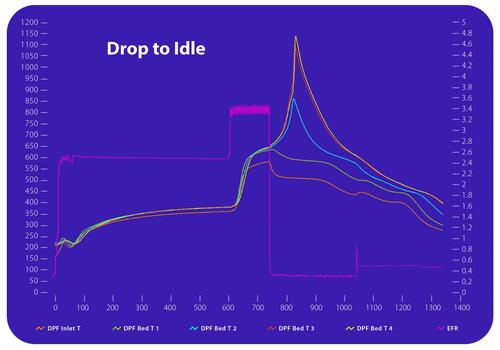

Various evaluation methods have been developed to measure emissions reduction, active and passive regeneration efficiency, pressure drop, thermal abuse, and ash loading performance among others.

Aftertreatment Test Cells, Software & Analytical Tools

SwRI has its own in-house developed test cell software written specifically to perform these non-standard tests. Additionally, a host of other capabilities exist at SwRI to complement this field including full EPA 1065 emissions measurement, material analysis, CT scanning, and chemical, fuel, and lubricant analysis.

Given the vast capabilities and experience of SwRI, OEMs, substrate suppliers, fuel and lubricant companies have all chosen SwRI for their aftertreatment evaluation needs. In many cases, dedicated test cells are available to minimize setup cost and time required to be on-test.