Rheology testing can provide greater insight into a fluid’s behavior beyond traditional viscosity testing. Southwest Research Institute offers a wide variety of rheological test methods for characterizing fluid behavior. It also offers many methods by which to measure viscosity that cannot be achieved using traditional viscometers.

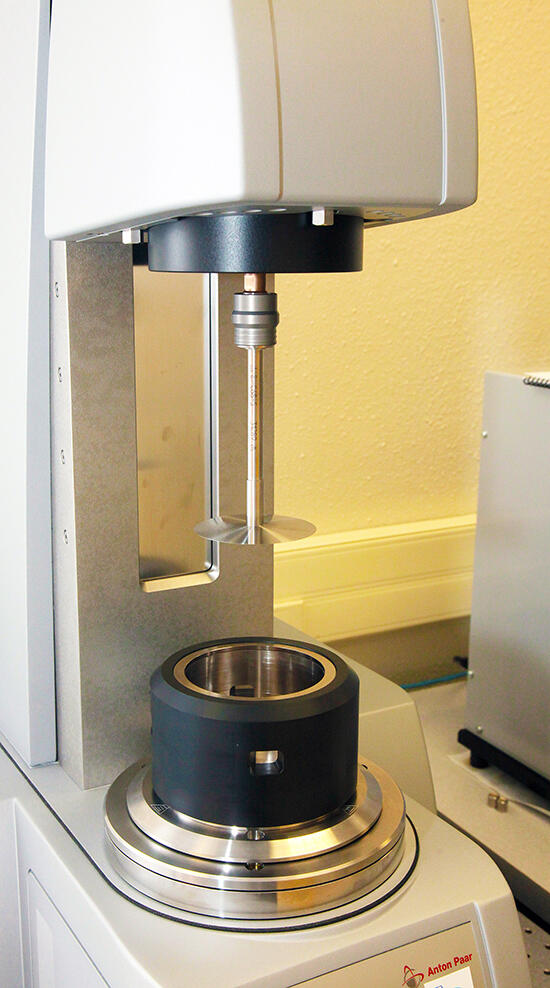

The Anton Paar MCR 502 rheometer is capable of numerous rheological tests, including the measurement of electrorheology, magnetorheology and pressurized rheology.

Rheology is the study of the flow and deformation of materials. This analysis technique can be used to characterize a wide range of fluids and semi-solids. Compared to a viscometer, a rheometer is a more complex instrument that offers a wide array of measurement options. A viscometer can only measure viscosity, while a rheometer can characterize the flow and deformation behavior of a fluid.

Rheology Testing Applications

Rheology testing has applications in many different industries, including:

- Oil and gas

- Automotive lubricants

- Grease

- Food and beverage

- Cosmetics

- Pharmaceutical

- Paints

- Adhesives

SwRI uses a variety of test methods in our laboratory.

Oscillatory Testing – Amplitude and Frequency Sweep

An amplitude sweep applies a controlled, increasing amplitude of strain at constant frequency to a fluid to measure the viscoelastic behavior. One measurement obtained from this type of test is the linear viscoelastic region (LVER) of a fluid.

A frequency sweep is typically performed after an amplitude sweep to obtain more information on a fluid’s behavior. This test apples a controlled, increasing frequency of strain at constant amplitude to a fluid to measure the viscoelastic behavior at different time scales. These test types are best suited for semi-solid materials such as greases, adhesives, sealants, and asphalt.

Thixotropy Test

Thixotropy describes the time dependent shear thinning behavior of a fluid. This type of test is typically performed in three intervals to measure the viscosity recovery magnitude and time after an applied shear. Thixotropic behavior is important in materials such as paints, where understanding the shear thinning and recovery behavior will allow for more consistent spreading and eliminating of brush strokes.

Creep Test

A creep test measures the elastic and viscous recovery and loss when an applied stress is removed. It is performed by applying a constant stress to a fluid for some time, then releasing it to allow the fluid to return to a state of rest. Creep behavior is important for materials such as asphalt and thick greases where the recovery behavior after an applied stress can affect how well the material remains on the surface.

Tack and Penetration Test

A tack test involves evaluating the tack or “stickiness” of liquid, solid, and semi-solid material through controlled separation of the material between parallel plates. This type of test is useful for the qualification of materials such as adhesives, greases, food products, cosmetics, and paints. A penetration test is performed in a similar manner to a tack test and can be used to analyze the stiffness of a material. The force, distance, and speed of penetration can be measured. This type of test is useful for materials such as foods, gels, sealants, and pharmaceuticals.

Interfacial Rheology Test

This is an analysis of interfacial layers at gas/liquid and liquid/liquid interfaces, or more specifically a measurement of the interfacial forces between interacting surfaces. This type of measurement is suited for the study of materials such as emulsions, foams, surfactants, and solvent based fluids.

Rheology Testing for Viscosity

SwRI utilizes several measurement systems to offer more comprehensive and customized viscosity evaluations. Rheology testing services for viscosity include:

- Temperature sweeps in the range of -20°C – 200°C

- Shear sweeps in the range of 0 1/s – 45,000 1/s

- Pressurized viscosity in the range of 0psi – 6000psi (1bar – 400bar)

- Viscosity under electric field (AC and DC) – Electro-rheology

- Complex viscosity of viscoelastic fluids

Watch the SwRI Tribology team in action.

Related Services

Or call Carlos Sanchez at +1 210 522 3663.