Pharmaceutical drugs are developed through a highly regulated process to ensure that a drug product, substance or formulation meets health and safety standards. Pharmaceutical testing laboratories provide analytical services used in the formulation of drug product for clinical trials and scale-up for manufacturing. Southwest Research Institute (SwRI) provides fully compliant facilities that support the testing, characterization and release of pharmaceutical products in adherence with CGMP manufacturing standards. Learn about our CGMP Manufacturing services and the Institute’s Pharmaceutical Development department.

Contact Sandra Drabik or call +1 210 522 6419 to schedule pharmaceutical analysis and testing.

Pharmaceutical Analysis Laboratory Services

SwRI has fully compliant pharmaceutical analysis laboratories to support the testing, characterization and release of drug product under industry standard chemical analysis procedures. SwRI’s pharmaceutical testing laboratory services support many various pharmaceutical formulations to include new chemical entity (NCE) and microencapsulation products (taste masking, tamper resistant, and controlled release). We support researchers, startups, manufacturers and other companies across the drug development supply chain in the following laboratories, among others:

- Analytical Pharmaceutical Services

- Stability Studies

- CGMP Manufacturing

- CMC Chemistry Manufacturing Control Services

- Chemical Analysis Services

- Microencapsulation

SwRI will develop and validate methods needed for your drug product / dosage form to include in your CMC section to include:

Assay and Impurity Test

The assay and impurity test determines chemical purity. Impurities present in a drug substance or drug product need to be closely monitored to comply with limits set forth in USP, EMA and other regulatory guidances. These impurities are either process impurities or degradants that can increase over time. Robust methods need to be developed and validated to track observed and possible impurities. When impurities reach a certain threshold level, they need to be monitored reported, identified and qualified depending on the level.

HPLC Drug Testing

The high performance liquid chromatograph, or HPLC drug testing, is a stability indicating method used to measure the active ingredients in a drug substance or drug product. SwRI uses HPLC test equipment to perform for assay and impurity testing.

Residual Solvent Analysis

SwRI performs residual solvent analysis with gas chromatography. Monitoring and controlling impurities, such as solvents remaining from API synthesis, is an important step in CGMP manufacturing. Head space gas chromatography conducted under the United Sates Pharmacopeial Convention (USP) Chapter 467 (organic volatile impurities) is the industry chosen method for analysis and quantitation. Solvents remaining in the API or dosage form are considered impurities and their levels must be controlled to industry established limits. After method development, SwRI will validate the gas chromatography method for use in release testing.

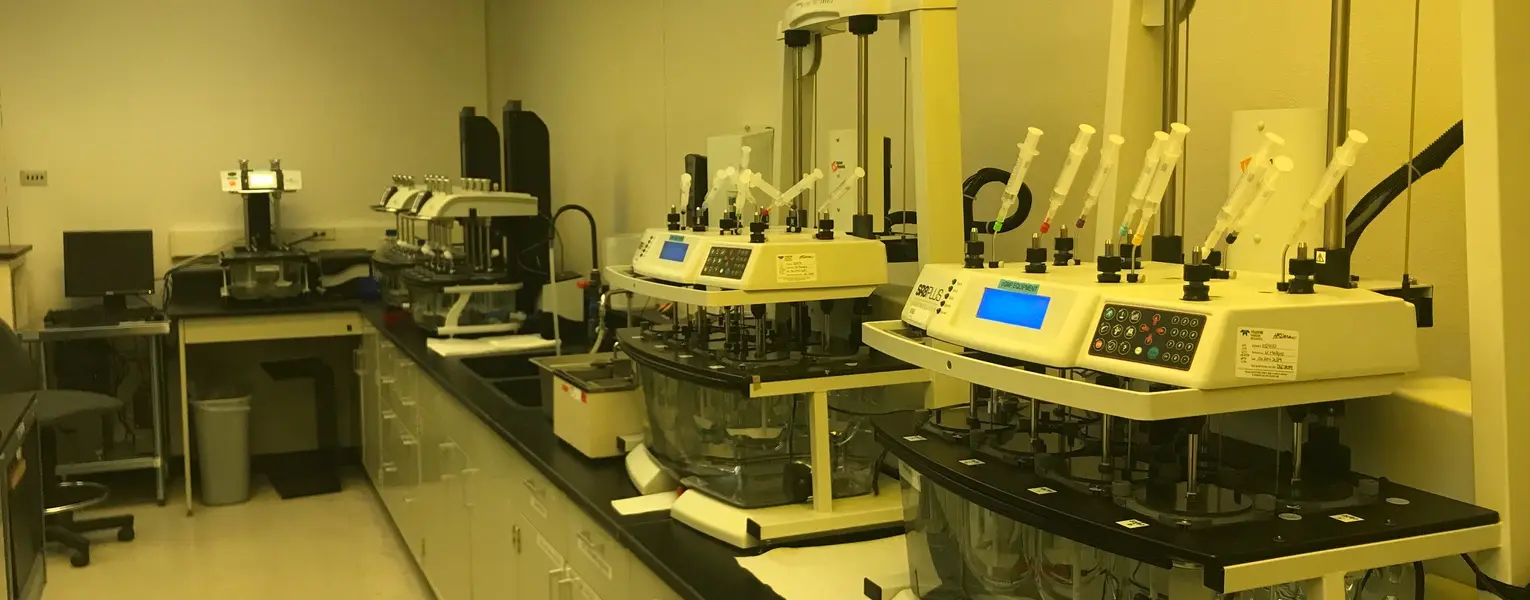

Drug Dissolution Testing

Drug dissolution testing is required to ensure a drug product functions as intended once it enters the body. SwRI performs in vitro dissolution and drug release testing in accordance with USP Apparatus 1 (basket), USP Apparatus 2 (paddle) and USP Apparatus 4 (SOTAX). Dissolution testing is often performed to evaluate performance of enteric coatings, or polymers used to coat oral tablets. An enteric coating must resist acid conditions in the stomach but release in the neutral environment in the lower gastrointestinal track. Additionally, controlled or extended release formations need methods developed to asses burst release and depletion of the active over time.

ICH Stability Studies

ICH stability studies help establish an expiry, providing guidance on testing of drug products for storage in various conditions. Controlled stability studies are conducted mimicking various climate zones throughout the globe. These studies also can accelerate the degradation (break down) of the drug or formulation which needs to be monitored to maintain a useful drug supply. The drug substance and drug product are stored in stability chambers that maintain precise control over temperature and humidity.

Particle Size Analysis

The size of a drug substance or product can impact its bioavailabity and solubility. Controlled release applications rely on particle size to predict their release characteristics in the body. SwRI can support particle size analysis from less than 1 nm through micron range.

TGA and DSC Analysis

SwRI performs thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC). TGA and DSC analysis are chemical tests that determine melting points and moisture in addition to the study of phase transitions such as melting and exothermic decompositions and glass transitions. DSC can be used to characterize crystal structure and polymorphs.

Additional Laboratory Analytical Services

We have a full complement of qualified and calibrated pharmaceutical testing instrumentation to include UPLC (ultra-high performance liquid chromatography), HPLC, GC (gas chromatography), nanoparticle sizing and characterization, and differential scanning calorimetry. Other Services include:

- Zeta potential

- Light degradation

- Impurity identification

- Active pharmaceutical Ingredient (API) and raw material release

- GMP product release

- Primary and secondary reference standard characterization

- GMP NMR analysis