Additive manufacturing (AM) is a process that involves the selective addition of material to “grow” a part layer by layer. In metal additive manufacturing, lasers melt feedstock into 3D shapes. This expands the design space by enabling fabrication of parts that would be too difficult or costly to produce with CNC and other conventional methods. Additive manufacturing is growing in popularity, but metal AM must overcome technical challenges that affect how the part is designed and built to produce a part that is equivalent or improved over a conventionally manufactured part. Southwest Research Institute helps industry and academia solve problems with metal additive manufacturing services focused on applied R&D.

Additive Metal Manufacturing Research

Additive metal manufacturing is infiltrating a range of industries and applications, including downhole oil and gas, automotive, power generation, biomedical, aerospace and space industries. Our metal additive manufacturing services include:

Radial turbine printed with selective laser melting.

- Prototype development – Designing parts for AM, post-build treatments, design optimization, and innovative applications

- Evaluation of AM builds – NDE methods to evaluate quality, porosity, surface roughness, chemistry analysis, property testing, and material/part qualification

- New materials and processes – Modeling the build process, custom powder manufacturing, novel materials, bonding dissimilar materials, shape memory alloys

Institute scientists and engineers solve metal AM challenges in these areas, among others:

- Advanced Power Systems

- Computational Materials & Modeling

- Engine Design

- Materials

- Mechanical Characterization & Testing

- Space & Ground-Based Instrumentation

MAKERS Initiative

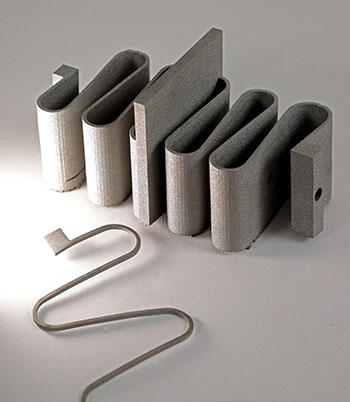

Shape memory alloy research with nitinol 3D printing.

SwRI’s internally funded Metals Additive Kickoff Emphasizing Research Synergy (MAKERS) initiative helps advance the collective understanding of additive manufacturing technology while fostering collaboration across technical disciplines. MAKERS projects include a small, cooled turbine for unmanned aerial vehicles, cooling jackets designed to enhance heat transfer in automotive engines, bonding materials to align ceramic joints in space craft, development of custom uniform feedstock powders, and detailed modeling of the additive build process. Lean more here:

Additive Manufacturing Aerospace Industry Solutions

Additive manufacturing has several aerospace applications including support for aging military aircraft. Replacement parts for older, damaged structural components can be hard to find due to obsolete vendors and fabrication processes. Sustainment problems may be mitigated by using AM processes to quickly produce one-off components. Our additive manufacturing aerospace industry solutions include simulation software and ceramic-to-metal bonding.

Selective Laser Melting Services

Selective laser melting (SLM) is a novel additive manufacturing process that involves dividing a computer-based rendering of the component geometry into a series of horizontal slices. SwRI uses selective laser melting for client projects and internal research. Each slice represents an individual layer of the part, which is built using a fine metallic powder. Software drives a laser that selectively melts and fuses regions of the powder to the previous layer. The process is repeated, building up a three-dimensional component layer-by-layer.

Shape Memory Alloy Research

Shape memory alloy deforms at lower temperatures then recover their original shape when heated. SwRI is researching novel approaches to 3D printing with nitinol (nickel titanium) and other additive manufacturing applications.

Related Technologies

- Additive Manufacturing

- Failure Analysis

- Machinery

- Mechanical Fabrication Center

- Metallurical Analysis Laboratory