Engines rely on flexible seals and gaskets between metal surfaces to perform the critical role of keeping fuel, lubricants, and combustion gases separate from each other. These rubber-like seals must withstand varying pressures and tensile forces under extreme temperatures over lengthy durations. When compromised or degraded by incompatibility with the oil or fuel in which they are immersed, seals can leak and fail, leading to costly engine damage. Changes in fluid composition or the presence of additives dosed at very low concentrations in the fuels and lubricants can affect the elastomeric function of the seals, resulting in embrittlement, swelling/shrinkage, and decomposition.

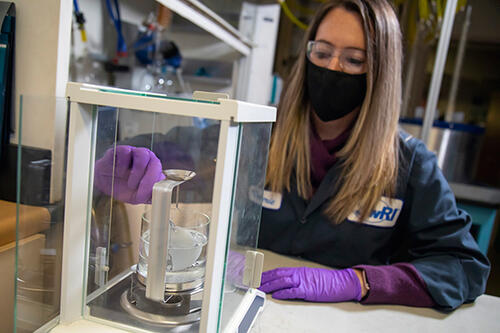

Volume swell and mass change testing with density balance.

Hardness measurement with durometer.

SwRI staff use dedicated instrumentation to investigate material compatibility between elastomers, O-rings, plastics, hoses, and coated fabrics with automotive fluids like gasoline, diesel fuel, coolants, and gear oils. Material specimens are cut to exacting standards using industry-recognized dies and evaluated on calibrated equipment for physical properties testing. These specimens are soaked in a candidate fluid alongside a comparative reference fluid for extended periods and at different temperatures, with subsets removed at fixed intervals for evaluation.

ASTM Material Compatibility Tests

SwRI performs the following ASTM Material Compatibility Tests:

- D256 – Impact testing (plastics)

- D395 – Compression Set (O-rings)

- D412 – Tensile Strength and Elongation (elastomers)

- D413 – Adhesion (hoses/materials)

- D471 – Thickness, Hardness, Volume Swell, Heat Aging (elastomers)

- D1414 – Thickness, Hardness, Volume Swell, Heat Aging (O-rings)

- D638 – Tensile Strength and Elongation (plastics)

- D751 – Coated Fabrics

- MIL-PRF-32233C – Collapsible Fuel Tanks

(Left) Tensile strength and elongation evaluated by Instron universal test machine. (Right) SwRI measures physical properties on a variety of material specimens.