Modern small industrial gas turbines are technically complex machines, consisting of multiple rotating parts, bearings, seals, lube oil systems and sophisticated electronic controls. The majority of gas turbine designs are optimized for highest efficiency but generally do not allow for portability and cannot handle severe environmental conditions; consequently, ruggedness is often sacrificed for efficiency. While this may be desirable for most permanently installed large power plant applications, it is not practical for small, portable, power-generation applications.

For a number of applications, customers desire simple, low-cost gas turbines that can:

- Function during very rugged environmental conditions

- Be easily repaired or replaced

- Be operated by untrained personnel

- Be moved easily

Many of these applications are within the upstream oil production or military power generation.

Radial Flow Gas Turbine

Southwest Research Institute (SwRI) is developing a novel radial flow gas turbine design. This extremely light, small and rugged gas turbine can provide a very simple power generation alternative. The gas turbine incorporates only one rotating part and has no lube oil or seal gas requirements, thus resulting in:

- Low manufacturing costs

- Low maintenance

- Low repair cost

- Low replacement cost

The simple design is:

- Highly portable

- Able to operate with a wide range of fuels

- Tolerant of ingested particles, such as sand or dirt

Because of the inherent robustness of the combustor design, the radial flow gas turbine can handle a wide spectrum of fuels including:

- Natural gas

- Liquid hydrocarbons

- Heavy oils

- Pure hydrogen

Description of the Radial Flow Gas Turbine

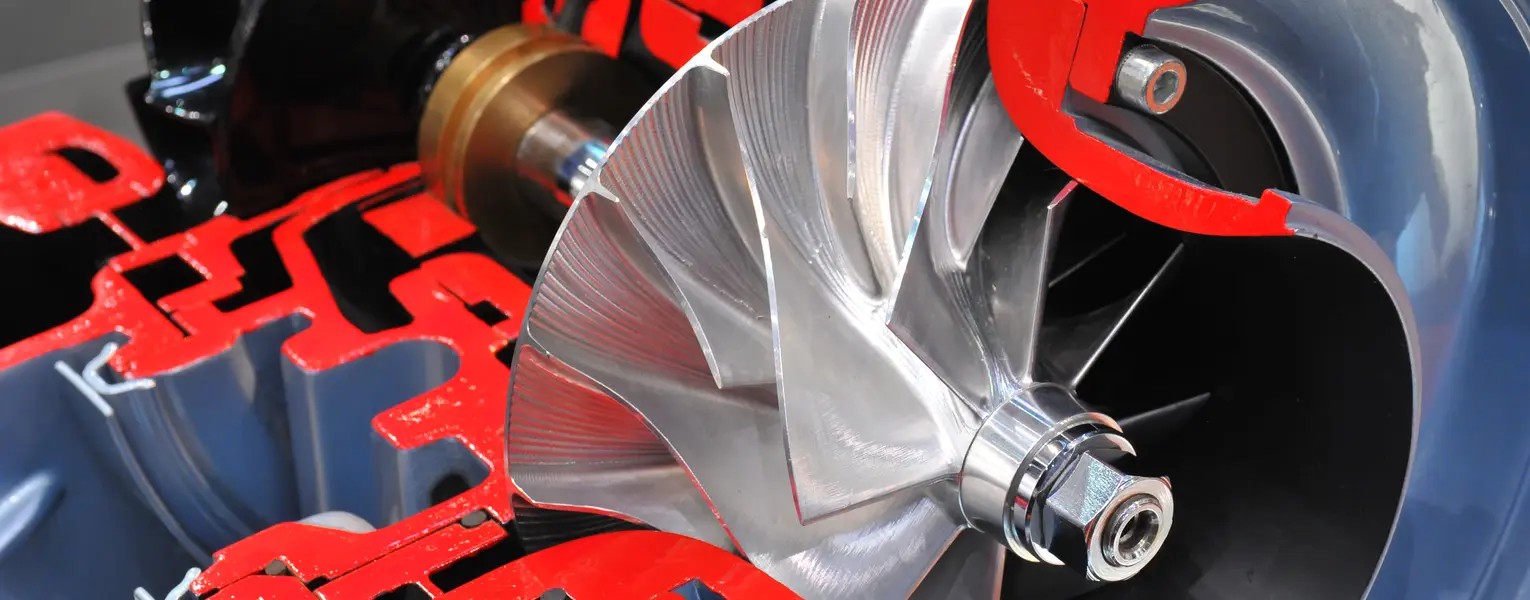

A single disk radial flow gas turbine is based on a straight radial flow design with no axial flow turning. This geometry contains only two major elements:

- Rotor Disk - Consists of a centrifugal compressor and high impulse radial outward-flow turbine connected to an electric generator (and starter motor)

- Stator Shroud Disk - Contains the combustor and nozzles, fuel lines are attached to the stator shroud disk and are ducted directly into the combustor

Function of the Radial Flow Gas Turbine

Flow enters the centrifugal compressor axially, is turned toward the radial direction and is compressed by the rotating blades of the centrifugal compressor. The flow exits the compressor section and enters the stator disk radial flow combustion section. Hot combustor exit flow is then expanded in the tangential direction by stator nozzles to drive the impulse turbine blades mounted on the rotor disk. Both compressor and turbine blades are mounted on the same wheel.

Radial Flow Design Advantages

- Single rotating component (i.e., mechanically simple and compact gas turbine)

- Rugged and portable

- Short axial span

- Simple two-disk construction

- Low manufacturing costs

- Easy maintenance and repair access

- High tolerance to injection of particulate matter

SwRI can offer you a full range of capabilities and experience in gas turbine technology including becoming an extension of your engineering department.

Contact us for more information about our radial flow gas turbine capabilities. To contract with SwRI, please contact the Machinery Services Hotline at +1 210 522 3000.

For more information, contact Tim Allison or call +1 210 522 3561.