In this Episode

Vehicles our communities depend on, like big rigs, garbage trucks and buses, are equipped with heavy-duty engines that contribute to smog. Ultimately, that pollution leads to poor air quality and public health issues. SwRI engineers have developed a solution. Their near-zero emissions heavy-duty diesel engine drastically cuts down on harmful nitrogen oxides, while decreasing other pollutants. After years of research, SwRI engineer Chris Sharp and his team are ready to introduce a game-changing technology in heavy-duty transportation that could benefit human health.

Listen now as we learn about a cleaner way to hit the road.

Transcript

Below is a transcript of the episode, modified for clarity.

Lisa Peña (LP): Less emissions, cleaner air. This goal inspired an advanced engine technology for big rigs and other heavy-duty transportation. Coming up, how SwRI engineers achieved an incredible feat, a near zero emissions diesel engine. That's next on this episode of Technology Today.

[MUSIC PLAYING]

We live with technology, science, engineering, and the results of innovative research every day. Now let's understand it better. You're listening to the Technology Today podcast presented by Southwest Research Institute.

Hello, and welcome to Technology Today. I'm Lisa Peña. Many of us continue to work from home, so we are recording this episode on the phone. SwRI engineer Chris Sharp is our guest today. He is leading a project considered a game-changer in transportation, specifically for heavy duty vehicles like 18-wheelers. After years of research, his team developed an environmentally-friendly diesel engine. Thank you for joining us today, Chris.

Image

Creating efficient, ultra-low NOx technology required a systems approach and multidisciplinary expertise. The SwRI team included (left to right) Institute Engineer Chris Sharp, Principal Engineer Gary Neely, Research Engineer Sandesh Rao, Research Engineer Bryan Zavala and Group Leader Sankar Rengarajan. Senior Research Engineer Shekhar Vats is not pictured.

Chris Sharp (CS): Thank you for having me, Lisa.

LP: So Chris, you and your team have come up with a potential solution for those emissions from the 18-wheelers on our road. Tell us about this technology you've developed. What is it, and how does it work?

CS: So the technology that we've developed is really an advanced, cutting edge aftertreatment system that can be integrated with a modern heavy-duty engine so that the total package has really near zero and, most of the time, zero emissions of harmful criteria pollutants and can do that in an efficient manner as well so that we can also try to realize improved fuel consumption at the same time.

LP: Have you been met with some, I guess, questions about, how is it possible? How are you able to achieve near zero emissions in a diesel engine?

CS: You know, in part, what we're doing is we're taking, because there's quite a bit of technology that's already on modern diesel engines, especially since about the 2010 timeframe. But we're really taking that technology to the next level. You know, already, since, you know, starting in 2010, emission levels that used to be out there were reduced by 90%. So that's already a big step. We have taken that already low level and reduced it by a further 90%, and so if you're looking, if you were to look at, say, an engine that might have been out there in the early 2000s, we're talking about being more than 99% lower in terms of criteria pollutant emissions, which is a big drop.

LP: So I want to hear a little bit about how this works. How did you figure out the right components to put together to achieve this?

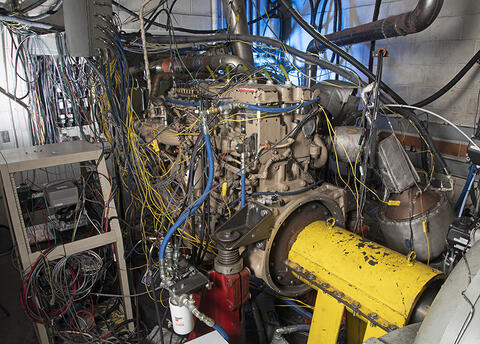

Image

SwRI engineers developed the next generation of clean diesel engine technology to reduce hazardous nitrogen oxides (NOX) and carbon dioxide emissions. In its ultra-low NOX test cell, SwRI combined engine modifications with integrated aftertreatment technology and control strategies to reach near-zero emissions levels.

CS: Sure. And you know, we've been leading this research effort, but I do want to make a little bit of a shout out to the fact that we have a lot of partners in this program. So we have industry partners. A lot of this is being done with technology that isn't just kind of in the lab research stuff, but it's really production ready technology. So it's the kind of stuff that really could get on trucks within the next few years in many cases. And so I wanted to highlight that as well.

And really, the primary thing that we've done is to take some of these new pieces of technology and integrate them into a unified whole system. So we are, for instance, leveraging SCR technology, or Selective Catalytic Reduction, which is already in place on a lot of diesel engines to an extent to reduce emissions of NOX, or oxides of nitrogen, which participates in forming smog.

And that technology already exists on trucks, but we've augmented it and made it better by using, by leveraging approaches like using a close-coupled catalyst technology to bring it closer to the engine to make it hot and get it hot faster and keep it warmer, and other technologies that allow us to just do that much better a job and to realize those emission reductions over the full range of real world driving.

LP: OK, so this project started back in 2013, when the California Air Resources Board contracted SwRI to develop this technology. When it started back then, what was the mission of this project?

CS: So the mission of the project initially is that, as you know, California, especially Southern California, continues to have air quality problems, and they're some of the worst air quality problems in the nation. So California, in particular, is very motivated to continue to try to reduce emissions of criteria pollutants like NOX that go into forming smog. And they are looking to further reduce emissions from a lot of different sectors, and one of the biggest sectors contributing to emissions is heavy duty trucking.

Image

SwRI Engineer Chris Sharp led the research and development of the Low NOX diesel engine technology.

And so they came to us to look at, could we develop and demonstrate the feasibility of technologies that could reach production that could demonstrate a 90% reduction in emissions of NOX from the current standards that exist today? But as a side part of that, we also needed to do it in a manner that was consistent with meeting future greenhouse gas standards, because there are now standards for fuel economy and CO2 emissions from heavy duty trucks that have been rolling out and will continue to roll out over the next 10 years or so.

And so while we needed to reduce NOX, because it's a public health imperative to do, we have to be mindful that we can't spend a bunch of fuel and increase CO2 emissions while we're trying to get rid of NOX. So we needed a technology package that was, that could do both things.

LP: OK, so let's talk about exactly what this technology achieved. You touched on it a little bit already, but this technology achieved 0.02 grams per horsepower hour for nitrogen oxide emissions, which is 90% below current national emission standards. So again, can you put this into perspective for us? That's a huge cut, and what does it mean?

CS: Yeah, so it means a couple of things, and actually, it's a little bit broader than just that standard number. That 90% reduction, though, really means that with technology like this applied, diesel engines, heavy duty truck engines, truly will be at a zero or near zero emission level. And actually, it will put them in the same kind of place that a lot of passenger cars currently are in, where once the engine has warmed up and is operating, which that may take a few minutes, there essentially are just about zero tailpipe emissions, again, with respect to criteria pollutants.

So there may be still a little bit that gets emitted when you're first cold starting the engine, which is typical to what current passenger cars do. But other than that, you're essentially going to be operating at a zero or near zero tailpipe level, at least to the degree that you can measure it. And so in that sense, it's really the end point of reducing emissions.

We've been trying to reduce criteria pollutant emissions for 30 years, and this brings them down to a level that really is just about zero, which would effectively put them, if you looked at it on a lifecycle basis, diesel emissions, tailpipe emissions would be comparable to the net emissions you'd get driving around with a battery-powered truck. They'd be that low. Of course, there'd still be CO2, so the job's not done yet, but in terms of harmful criteria pollutants, the ones that contribute to public health issues, there really wouldn't be anything coming out of them. And that's a big deal.

I think one of the other points, though, that gets lost a little bit in the 0.02 is that what we've done with this system is more than just reach 0.02 on some of the, I'll call them the certification cycles, because engines are usually certified in a laboratory. But one of the issues that has been significant for current systems is that while they are very efficient under piloted conditions, in real world driving in urban environments where lots of people are, the current systems don't function as well. The standards did not require them to necessarily function as well under those kind of challenging operating conditions.

And so emissions from current heavy duty trucks under low load and urban driving environments, things like maybe a garbage truck picking up things that goes down the streets, are still quite a bit higher, even than the current standards. And so one of the things that we've done with this technology is not only reached 0.02 on laboratory cycles, when the engine is operating, say, under highway cruise. But even under these low load and challenging conditions, we are still achieving emission levels that are down around these kinds of levels.

And so that's a big change in how things are done right now, and it probably represents the greatest area for improvement from this technology is how much better it can control emissions at low loads, in urban environments.

LP: So near zero emissions, as you said, this is a big deal, and the California Air Resources Board says this type of technology is exactly what we need to create sustainable, heavy duty transportation and meet public health obligations long term. So what is the big picture potential of this technology? When we say near zero emissions" and "lowering the emissions" coming out of these big trucks, what does that mean for all of us?

CS: Well, what it really means for all of us at the end of the day is cleaner air. It means that we can, with these kinds of technologies, what we can ultimately do is we're effectively looking at eliminating the impact of transportation on public health in a big way. And that's a huge thing.

I happen to have a daughter that suffers from asthma herself. I remember her going to a soccer tournament in Southern California and coming home and having to do a week's worth of breathing treatments, because she, her lungs were irritated. So I have a very personal experience with this kind of thing now.

And there's a lot of people in the country that still live in areas that have compromised air quality, and we've made huge strides since kind of the miserable smog of the 1970s. But the air is not healthy yet, and people who are compromised, older people, children, people that have asthma, still suffer a lot of health effects and a lot of difficulty, because the air is not as clean as it could be.

And transportation is a big part of that right now. When we get technologies like this on to all the vehicles that are running around out there, then if you're really at zero or that near zero, then you really are eliminating that problem. And that's a huge improvement in quality of life for a massive number of people.

LP: Yeah. Thank you.

CS: In the U.S. now is what we're looking at. But really, there's international interest in this technology, and so you start looking at other places, places like China and India that have terrible air quality problems, ultimately, this kind of technology can contribute globally to improving people's quality of life so you know that's why it's really a big deal.

LP: Yeah, thank you for sharing that story about your daughter, because I think that really connects the dots for us. This isn't just an engineering issue or a transportation issue. This is really a public health breakthrough, which all of us can benefit from. And I think that's what the amazing part about it is and why, as you said, this is a big deal. And it's good for people to take notice, know this is happening.

So California intends to enact tighter emission standards by 2024, and this engine technology can meet these high standards. And so that's California, and you just mentioned you that impact communities globally, but do you envision these standards actually being adopted on a national level?

CS: Yeah, there actually is already a movement afoot. And again, we don't really know exactly what the final numbers are going to be nationally yet, because that's still a subject of discussion and research. But the EPA has already announced last year what they call their Cleaner Trucks Initiative. And the intent behind those is to deploy a lower NOX standard on a national basis. So EPA is already coordinating with California. They are involved in this same research, and they are actually picking up and beginning to do their own research in this area, which Southwest Research is also supporting.

So when we do expect that they are also going to enact tighter emission standards, EPA is not on the same timeline as CARB. They also have some federal rules that mandate certain processes they have to go to, but what we're expecting from EPA is that they will be, in fact, we expect they'll probably be announcing a proposal before the end of this year and likely finalizing a rule next year that will be enacted in the 2027 timeframe, which, for California, is also when they expect these standards to sort of fully phased in as well, is by 2027.

LP: Because really, one state is great, but on a national level, we can really have an impact on cleaner air if everyone had a role in that. So I do want to go back to how we were talking about not being the focus, but you're also working on lowering other types of emissions like carbon dioxide. And you were able to accomplish some of that, but as you said, there's still work to be done. But can you tell me about your work in that area?

CS: So yeah, the aftertreatment system, and again, this is an area in a lot of other pollutant emissions that even from 2010, there's been immense strides in the capability of these kinds of diesel treatment systems. And so in that sense, we've maintained that functionality. When you look at things like particulate emissions in the soot and the smoke that used to come out of diesels, those levels are effectively at zero levels already. And so we need to maintain that kind of good functionality as we develop NOX emissions.

To some extent, NOX is sort of the remaining problem for diesel engines, because a lot of the other ones had already been sorted out previously. And so we need to make sure that we maintain that already great functionality, while we improve NOX emissions.

CO2 is a little bit tougher nut to crack, because it's a result of actually burning fuel. So when you talk about trying to reduce CO2, what you're really talking about trying to do is improve fuel consumption, and just reduce fuel consumption. That's pretty tough to do already, and one of the concerns with NOX emissions is because of the things that we have to do to improve NOX emissions, if we don't do those carefully and in the right way, it would be possible to actually make carbon dioxide emissions a little bit worse.

And so one of the big keys to the technology package that we put together is that we can achieve these big NOX reductions without having a negative impact on CO2, or, in the best cases, actually resulting in some improvements. For the heavy duty diesel market, it's already a pretty efficient market that people use these trucks to make money. They want them to be as fuel efficient as possible. And so there, even small changes, a couple percent here or there, are a big deal, because a lot of fuel gets burned, and a lot of money gets spent.

And so there are some areas which our technology package, at the end of the day, has actually realized some small benefits, a couple of percent here or there. Under other conditions, we've held the line and made sure that we could reduce emissions without having a negative impact on CO2.

LP: So how did you do it? Was there a key technology integrated in the engine that made it possible?

CS: Yeah. There was, and a lot of it, part of it boils down to the design of the aftertreatment system. So we want to minimize the level of heat energy that we have to add to the aftertreatment system to make it functional. And so the aftertreatment design helped with that. But that alone wasn't going to be enough.

We needed another technology level to really take it to the next level, and the technology that we actually integrated onto the engine as part of this is something called cylinder deactivation, which is actually a technology that's been on some passenger car engines used differently for a number of years already in production.

There's a number of GM vehicles and others that have it in place, but for heavy duty engines, cylinder deactivation is a new technology. But it really does offer the promise of being able to, in combination with the other technologies we use, realize some improvements both in NOX, getting us to this near zero level, but at the same time, actually showing some fuel consumption benefits under some kinds of operating conditions, especially these lower load operating conditions.

LP: OK, and just to clarify, I wanted to talk a little bit about the technical terms you used. Can you tell us what an aftertreatment system is, and then what a cylinder deactivation means?

CS: Sure. So an aftertreatment system is essentially, that's industry jargon for a catalyst system that takes the exhaust from an engine and cleans up all of the harmful emissions so that you have clean exhaust coming out of the tailpipe. Engines do produce emissions. You can't get rid of those from the engine itself. There just isn't a way to do that while the engine's still operating in an efficient manner.

And so instead, we apply a system afterwards, which is why we call it an aftertreatment system, in the exhaust, to clean up those harmful pollutants, so they don't get emitted into the atmosphere. And so a catalytic converter on a passenger car is an aftertreatment system. And so in that sense, there's been aftertreatment on at least passenger cars since the mid-1970s.

LP: OK, and then the cylinder deactivation.

CS: So cylinder deactivation is a very interesting technology, and what it basically involves doing, you know, most engines, you know, an engine is a multicylinder internal combustion engine with pistons, right? And so it has multiple cylinders. Normally, they all run. And in a conventional engine, they all have to run all the time, but you may not actually need all of them. If the engine is running at light load, you may not really need all those cylinders running in order to produce the power that you're trying to produce under a lighter load condition or, say, when the engine's idling.

But you're still doing a bunch of work to pump air through all those cylinders. You're cooling off aftertreatment systems, so we're just doing a bunch of stuff we don't need to be doing. The beauty of cylinder deactivation is that when you don't need all those extra cylinders, you can turn them off, so you turn off the fuel injection, and you close all the valves, so those cylinders are not breathing air. And by doing that, you accomplish a number of goals.

One, you save some fuel because of reduced pumping losses and friction losses, but you also reduce the amount of cold air that may be blowing through your aftertreatment system, cooling it off and making it work less effectively. And so we're really kind of getting both of those things at the same time using cylinder deactivation.

LP: So when do you see this technology being widely available for heavy duty transportation manufacturers?

CS: Well, so the technology is available now, although I shouldn't say, you're not going to see it tomorrow. It requires a lot of engineering and a lot of development to really take these technologies and put them into production. But really, certainly by 2027, in time for the standards that CARB and EPA want to promulgate, kind of the final phased in standards, all of these technologies that we're talking about now should be available in production. Some of them are available sooner, like in 2024. Some of them may take a little bit longer, and that's really going to be up to the individual manufacturers of trucks to decide, what combination of technology do they want to employ and when?

LP: By the end of the decade, we could see this widely used in trucks on the road.

CS: Exactly, yeah. On lots, and it's not really just the big 18-wheelers. This kind of technology applies all the way down into step vans, delivery trucks, really anywhere that you see heavy duty or medium duty engines being used, so driving around neighborhoods, too.

LP: Yeah, so maybe buses.

CS: Buses, yeah. You know, anywhere that we're...

LP: Anything heavy duty.

CS: Yeah, anything that's heavy duty or medium duty, trash trucks going down through the neighborhood, all that stuff.

LP: Yeah. OK, so was there ever a point where the goal of near zero NOX emissions seemed too lofty or out of reach?

CS: I don't know that, I think we were confident that we would always be able to reach at least near these kinds of levels. There are a couple of points where it's become quite difficult. Probably the biggest challenge associated with this is the fact that these systems, you know, it's one thing to make them work when everything is relatively new, when the catalysts are fresh.

The more difficult challenge, in some ways, is maintaining that over the time that a truck's going to run. And remember that trucks are required to control emissions currently for 435,000 miles, which is about four times what a passenger car is. But they can often run for 800,000 or a million miles.

And so continuing to control emissions after years and years of real world operation, degradation, and exposure to lubricating oils, and all the other things that happen is probably the biggest challenge associated with meeting these kinds of standards. And that's what's made it the most difficult. And in some cases along the path here, we have been you know close to 0.02, but maybe not always under 0.02. So there's some of the steps along the way, we've seen numbers 0.023 and 0.025. And I don't know that doesn't sound like a big difference, but you know.

LP: Was it a big day in the lab when the 0.02 was achieved?

CS: Yeah, it really was pretty exciting stuff. And for me, I've been working in emissions now for nearly 30 years. And when I started, diesel engines like this put out numbers like 6 grams per horsepower hour and 10 grams per horsepower hour. And now we're talking about numbers like 0.02, so you're talking about a more than 99.5% less, 99.7% less than when I started working.

And I've been participating in technology demonstrations like this for many years. And so to make a big step like this, it really is pretty amazing for me to look at the measurements and see that even under some of the most difficult operating conditions, we're just looking at almost nothing coming out of the tailpipe in terms of NOX emissions. It's pretty amazing.

LP: Yeah, that's a huge jump. Not knowing the history of, that you're talking about 10, 6, now to 0.02. But hearing that, I mean that is huge.

CS: Yeah, it's multiple orders of magnitude.

LP: Yeah. So I do want to ask you a question, given your experience in studying emissions and dealing with emissions and just kind of keeping an eye on that data. Since people around the world have been under stay at home orders, we've all been home and not traveling as much. There have been reports that pollution levels have significantly dropped. Any insight on what impact that could have long term? Have we paused long enough to make a difference?

CS: You know, in the long term sense, I wouldn't expect to see that just from this, right? You know, once industrial, I would fully expect that the economy is going to recover. Industrial activity and transportation is going to restart. And a lot of those levels are going to go back up to where they were beforehand.

I think, though, the impact this might have, though, maybe plays differently in terms of how people view this problem, because, of course, there's always a lot of discussion, are we really contributing to these things? I mean folks, some folks just aren't sure they believe that yet. And I think what we've seen from this, we've got a major drop, very sudden drop for a long enough period of time that you can see it in transportation and industrial activity. And we've now seen, through our measurements, that that's resulted in a significant drop in emission rates.

I think what that does, for people looking at it, is to look at that and say, yeah, you know what? It is us. We are, in fact, having a real impact on the environment through emissions. And if we weren't doing all this activity, it'd be less. So I think that tells us that we are having an impact on the environment like this. I think it drives that point home, and hopefully, what that can highlight to people is that doing something about this, trying to get these kinds of technologies out there that really reduce emissions would have a real impact on the environment.

LP: And that's exactly what you and your team are doing, and it's obvious that you're passionate about this work and excited to bring this technology to the world, really. So what do you enjoy about your work?

CS: I think more than anything, it's just getting a chance to work with all these new technologies and bring them together. I'm leading this effort, but there's a huge team of folks behind me at Southwest Research Institute, and then really beyond that with all our industry partners. And I think it's really great to be able to pull together all these technologies, and use them in a new way like this to really make an impact.

That and, you know, there's a lot, from an engineering standpoint, for an engineering geek like me who gets into all this stuff, there's a lot of little challenges and sort of nuggets of information and things that you learn, and it's exciting when you get to be the first people to see that kind of stuff happening. It's just, it's pretty good stuff. It's kind of why I do this.

LP: So what do you hope for the future of this diesel engine technology?

CS: Well, what we hope for, and I think there's a good chance to see it, is that we get to see this stuff deployed. I'm excited, and we've got a laboratory demonstration here, but there's a good bit of work, a lot of work to take this laboratory demonstration and really turn it into products on the road, you know, a quarter million trucks a year coming out with this kind of technology on it, working well, meeting people's needs. There's a lot of work yet to come to make that happen, and it'll be exciting to see people pick up what we've started and really turn it into that real production reality. I think that's going to be kind of probably the most exciting thing to see.

And we're already beginning to move into other areas with this kinds of technology, so recently, we've started to work on non-road engines, so construction engines, tractor engines, things like that. And so I think the other thing that's going to be, the next real phase of work as we, and we're not done with this yet. We're still working on it. But even as that phases into other areas of where diesel engines are utilized, I think we're looking forward to meeting some of those challenges as well, because every one of these markets is a little different.

LP: So this is a technology with huge potential. And when those of us not in your field hear a new diesel engine technology, as we discussed, we might not think it impacts us. But really, this is a development for everyone, and if widely adopted, it could clean up the air we breathe and benefit cities around the world. So it could have a huge impact, a big impact. So I congratulate you and your team for this important work, and thank you for talking to us today, Chris.

CS: Thank you, Lisa. Enjoyed doing it.

And that wraps up this episode of Technology Today. Our segments Breakthroughs and Ask Us Anything are on hold for now. We'll be back in our podcast studio as soon as possible.

Subscribe to the Technology Today Podcast to hear in-depth conversations with the people changing our world and beyond through science, engineering, research and technology.

Connect with Southwest Research Institute on Facebook, Instagram, Twitter, LinkedIn, and YouTube. Check out the Technology Today Magazine at technologytoday.swri.org. And now is a great time to become an SwRI problem solver. Visit our career page at swri.jobs.

Ian McKinney and Bryan Ortiz are the podcast audio engineers and editors. I am producer and host, Lisa Peña.

Stay safe and thanks for listening.

[MUSIC PLAYING]

We set the bar for new methodologies of characterizing engine exhaust constituents for vehicles of all sizes and fuel types. We are a global leader in the measurement of particulate emissions. Our specialists engage clients with certification and audit testing services.

How to Listen

Listen on Apple Podcasts, or via the SoundCloud media player above.