Click below to jump to an article of interest.

STEP Demo Pilot Plan Achieves Supercritical CO2 Conditions

A $155 million, 10-megawatt supercritical carbon dioxide (sCO2) test facility at SwRI in San Antonio, developed in collaboration with GTI Energy and GE Research and sponsored by the U.S. Department of Energy (DOE), has successfully achieved its first operation with sCO2 at supercritical fluid conditions in its compressor section. This accomplishment represents significant progress toward readying the Supercritical Transformational Electric Power (STEP) Demo pilot plant for system-level testing.

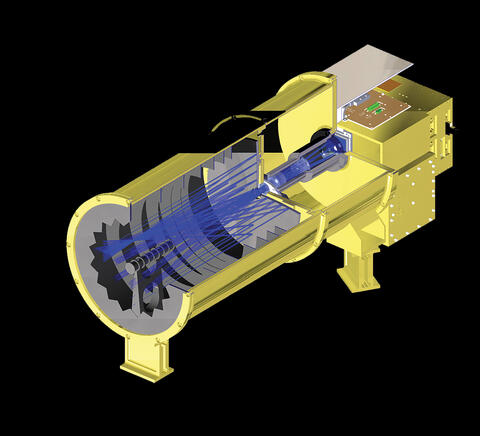

SwRI designed and manufactured this unique sCO2 turbine for installation into the STEP demonstration pilot plant. Testing will begin later this year.

“This exciting milestone represents a significant advancement for a truly transformational project,” said Dr. Tim Allison, director of SwRI’s Department of Machinery. “STEP Demo is laying the groundwork for power generation that is more efficient, with a smaller footprint.”

Unlike conventional power plants that use water as the thermal medium, STEP is designed to use high-temperature sCO2 to increase efficiency by as much as 10% due to its favorable thermodynamic properties. Carbon dioxide is nontoxic and nonflammable and, when held above a critical temperature and pressure, can act like a gas while having a density near that of a liquid.

The efficiency of sCO2 as a working fluid allows for STEP turbomachinery to be approximately one-tenth the size of conventional power plant components, providing the opportunity to shrink the environmental footprint and construction cost of new facilities. For example, a desk-sized sCO2 turbine can power up to 10,000 homes. The technology is also compatible with concentrated solar power and industrial waste heat.

“The sCO2 power cycle is a breakthrough clean, compact and high-efficiency power generation technology that can deliver significant environmental performance,” notes Bhima Sastri, director of the DOE Office of Fossil Energy and Carbon Management Energy Asset Transformation Program. “We look forward to continued operation of the current test to demonstrate control and operability of this power cycle while validating system performance over long periods of time.”

SwRI’s John Klaerner, left, lead turbine engineer, and Dr. Jeff Moore, right, principal investigator of the STEP Demo project, are pictured with the recently assembled sCO2 turbine for the10 MWe demonstration plant under construction at SwRI.

The STEP Demo pilot plant is one of the largest demonstration facilities in the world for sCO2 technology, designed to dramatically improve the efficiency, economics, operational flexibility, space requirements and environmental performance of this new technology. The team is installing the sCO2 turbine for testing later this year.

SwRI is an industry leader in the development of sCO2 power cycles. Staff members have conducted numerous related DOE projects advancing the efficiency, reliability and commercial readiness of sCO2 power cycle turbomachinery, heat exchangers, cycles and systems.

“Our team brings extensive experience with sCO2 technology and the key building blocks to make the STEP Demo project a success and a landmark demonstration,” Allison said.

Innovative, Efficient Hydrogen Compressor Supports FCEV Refueling Stations

SwRI developed a new hydrogen compressor designed to improve the efficiency and reliability of technology used to refill fuel cell electric vehicles (FCEVs). The linear motor reciprocating compressor (LMRC) is hermetically sealed and includes a linear motor driven design.

“LMRC was built and designed to compress hydrogen for refueling vehicles with hydrogen fuel cells,” said SwRI Principal Engineer Eugene Broerman, the project’s lead investigator. “To refuel hydrogen vehicles, the gas must be compressed to high pressures first. So, we set out to design a more efficient, leak-proof compressor.”

A key challenge for hydrogen compression is hydrogen’s small particle size, which increases the potential for leaks as the gas flows through equipment.

“Because hydrogen particles are so small, there are inherent material compatibility issues when designing a compressor,” Broerman said. “The small particles can sneak in and alter materials and equipment performance. For instance, we had some early issues with the hydrogen particles causing magnets to fail, so we had to coat the magnets more effectively to prevent that.”

The novel LMRC features an airtight compressor, hermetically sealed using a combination of SwRI-developed solutions. Coatings protect magnets from hydrogen incursion and embrittlement, while improved valve designs minimize leaks. It also utilizes a ceramic piston to minimize heat expansion and lower stress on its seal.

“Typical compressors have a piston and crank mechanism that requires them to make the same motion every time, with every revolution of the motor that’s driving it,” Broerman said. “SwRI’s LMRC is linearly actuated, so we can change the linear motion profile to optimize the compression process.”

To avoid contaminating the hydrogen gas, most hydrogen compressors are oil-free mechanisms. Most reciprocating compressors have motors that repeatedly make the same motion and require lubrication for maintenance. Mounted for vertical motion, LMRC’s linear motor employs a unique dynamic seal design and moves the piston in a user-defined pattern. As a result, the compressor’s seals and bearings experience less friction, negating the need for traditional lubrication. The leak-proof compressor can be adapted for other applications, such as hazardous gas or flare gas recovery.

Originally funded by the U.S. Department of Energy and cost-shared by ACI Services, LMRC has since been supported by internal research funding at SwRI. The LMRC was successfully run for the first time in 2020 and completed continuous operation at design conditions in 2022. Going forward, Broerman plans to modify different aspects of LMRC’s design to increase efficiency and speeds to boost flow rates and apply the technology to other compression applications requiring hermetic sealing.

“These types of projects are critical to advancing compression technology as the hydrogen economy continues to grow,” Broerman said. SwRI has a multidisciplinary team dedicated to hydrogen energy research initiatives to deploy decarbonization technologies across a broad spectrum of industries.

Transnational Sustainable Manufacturing Program

SwRI and Tecnológico de Monterrey (Tec de Monterrey) are jointly funding three research and development initiatives to advance sustainable manufacturing and technology in the United States and Mexico. The trio of projects are the first selected and supported through the Sustainable Manufacturing Program, a transnational research and development collaboration established between SwRI and Tec de Monterrey — a private, nonprofit, independent university based in Monterrey, Mexico — in August 2022. The program provides grant opportunities funded by both organizations.

“We look forward to the progress that develops from this collaboration and the long-term impact of this research on industry and the planet,” said SwRI President and CEO Adam L. Hamilton, P.E.

Sustainable manufacturing practices conserve energy and natural resources, using technology and materials that protect the environment while supporting technical advancements. Each project includes researchers from both organizations.

SwRI’s Eloy Flores III and Dr. Michael MacNaughton are collaborating with Tec’s Dr. Alejandro Montesinos-Castellanos and Dr. Ladislao Sandoval Rangel on a carbon capture and utilization project to reduce carbon dioxide emissions, creating biochar using unique pyrolysis processing techniques. The team is evaluating the capture and storage properties of the charcoal-like substance (seen right), which can also be recycled for other uses, such as fertilizing soil.

SwRI’s Alice Y. Yau and Tec’s Dr. Cecilia Daniela Treviño-Quintanilla are investigating how to recycle and reuse industrial rubbers and plastics, which often end up in landfills or oceans. Researchers will break down the materials to create environmentally friendly raw materials that could potentially support production of foams, adhesives, coatings and other industrial and biomedical materials.

SwRI’s Matthew Kirby and David Riha along with Tec’s Dr. Alex Elías-Zúñiga are developing a recyclable carbon-fiber-reinforced polymer composite using an innovative forging process that is more energy-efficient than traditional techniques. Lightweight composites used for high-strength applications are typically hard to recycle.

Safer, More Effective Hydrogen Injector for Gas Turbines

SwRI engineers are designing innovative “green” hydrogen combustion systems for gas turbines used in power generation. The designs prevent flashback, a common concern in hydrogen-fueled combustion systems, which can damage fuel nozzles.

Hydrogen fuel has numerous benefits — notably, it produces no carbon emissions during the combustion process. However, it’s highly reactive, which makes it more difficult to control than natural gas or the liquid fuel typically used in gas turbines.

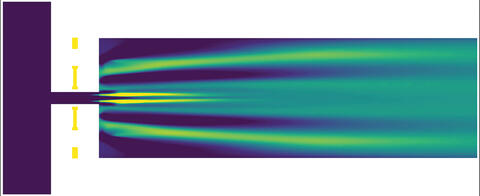

SwRI is exploring the use of “green” hydrogen fuel for gas turbines used to generate power. The designs include a nozzle that rapidly mixes and injects air (dark blue in the image) and fuel (yellow in the image) into the combustor to prevent flashback, a common hazard in hydrogen-fueled power generation applications.

“With pure hydrogen fuel, traditional low-emissions designs are highly susceptible to a damaging phenomenon known as flashback,” said Griffin Beck, manager of SwRI’s Propulsion and Energy Machinery Section. “This occurs when the flame in the combustor flashes back into the nozzle, which can damage the equipment.”

To remedy this, SwRI is exploring novel ways to mix air and hydrogen within the nozzle while avoiding flashback. The designs generated as part of the project support the development of a 100% hydrogen-fueled combustion system for an industrial gas turbine while also targeting very low nitrogen oxide (NOx) emissions.

“While hydrogen does not create carbon dioxide emissions, it does create NOx,” Beck said. “However, when air and hydrogen are mixed efficiently in the nozzle, NOx emissions are significantly lower.”

SwRI used computational and analytical tools to design a unique nozzle that rapidly mixes air and hydrogen through small, perpendicular pathways. The design then forces the mixture out of the nozzle and into the combustor at flow rates that prevent flashback.

Cost-Effective Pathways for Malaria Medicine

SwRI collaborated with The University of Texas at San Antonio (UTSA) to develop a new chemical technology to make the highly potent antimalarial drug artemisinin, which could lead to more cost-effective treatments. Recently featured on the cover of the scientific journal Organic Letters, the work was supported by the Bill and Melinda Gates Foundation as well as by a Connecting through Research Partnerships (Connect) grant, a joint SwRI-UTSA effort to enhance scientific collaboration between the two institutions.

In 2021, 247 million cases of malaria led to 619,000 deaths worldwide. The most effective malaria treatments use the drug artemisinin, which is derived from the sweet wormwood plant, Artemisia annua. However, the process of isolating artemisinin from the plant is time-consuming, and crop yields are susceptible to weather patterns, insect infestations and other factors. Despite scientific advancements in treatment methods, the cost of artemisinin still burdens the countries most affected by malaria.

SwRI collaborated with UTSA to synthesize highly potent derivatives of the antimalarial drug artemisinin, which could lead to a more cost-effective treatment for the deadly disease.

The most effective malaria treatments use the drug artemisinin, which is derived from the sweet wormwood plant, Artemisia annua.

“We were able to develop a novel way of synthesizing artemisinin that mimics how it’s made in nature,” said SwRI Senior Research Scientist Dr. Shawn Blumberg. “Our method mimics the biosynthetic pathway of how artemisinin is made in the plant where it originates. We studied the intermediate compounds along that pathway and then used chemistry to create those same intermediates and recreate the pathway.”

In 2020, Blumberg and UTSA Professor Dr. Doug Frantz received a $125,000 grant from the Connect program to build on work supported by the Bill and Melinda Gates Foundation to create a more cost-effective way to synthesize artemisinin.

“Nothing in public scientific literature suggested this would work,” Frantz said. “This was challenging chemistry that we were trying to pull off, but we let science tell us where to go. It enabled us to design a process of taking a common intermediate in the biosynthetic pathway for artemisinin and converting it all the way to artemisinic acid, which is the direct precursor to artemisinin.”

With drought, wildfire and insects making it difficult to depend on sweet wormwood yields, Blumberg and Frantz hope drug companies can use this new method to produce a more potent and cost-effective malaria treatment, especially for the impoverished countries often most affected by the disease.

“The supply of artemisinin remains somewhat erratic, which causes price instabilities, and countries dealing with this endemic need a stable, cost-effective solution,” Blumberg said. “While the new process we’ve created might not completely supplant current methods, it can complement other approaches and help to stabilize the world’s supply of artemisinin.”

Eclipse Down Under

Through the Citizen Continental-America Telescopic Eclipse (Citizen CATE) 2024 project, SwRI scientists led a team to image the Sun’s outer atmosphere, the corona, during a short solar eclipse on the opposite side of the Earth. Using four platforms in the northwest corner of Australia, the team successfully observed the million-degree solar corona at the April 20 eclipse viewed from the town of Exmouth on the North West Cape peninsula. The Australian eclipse serves as both a unique scientific opportunity and a training exercise for the program’s leadership in preparation for the 2024 U.S. eclipse.

The CATE 2024 team traveled nearly 10,000 miles for one minute of totality to observe the Sun’s corona from the unique perspective offered by total solar eclipses. These phenomena allow scientists to view the complex and dynamic outer atmosphere in ways that aren’t possible or practical by any other means. SwRI is leading the Citizen CATE 2024 experiment, a broad scientific outreach initiative that will make a continuous 60-minute high-resolution movie during the April 8, 2024, solar eclipse over the United States. CATE 2024 will use a network of 35 teams of citizen scientists representing the local communities within the eclipse shadow path.

“Even though the Australian eclipse was very short, our team of community scientists performed flawlessly and captured fabulous images of the structure of the elusive solar corona,” said Dr. Amir Caspi, a principal scientist at SwRI in Boulder, Colorado, and leader of the Citizen CATE 2024 project. “This eclipse provided the perfect opportunity to test our equipment and procedures, and to train our community leaders for the next eclipse in 2024.”

The SwRI-led Citizen CATE 2024 project is funded by grants from the National Science Foundation and NASA. Beyond its scientific goals, the project aims to engage many unique and diverse communities along the eclipse path as an integral part of a major scientific research effort.

The current project builds on the experience of the first Citizen CATE experiment, expanding the scientific objectives by measuring polarized light and engaging with teams across the new eclipse path. Dr. Sarah Kovac, a 2017 CATE participant and now a postdoctoral researcher at SwRI, serves as project manager for the 2024 expedition.

“Participating in CATE as a young undergraduate inspired me to pursue a career in heliophysics,” Kovac said. “Seven years and one Ph.D. later, I get to be on the professional side of planning an eclipse expedition, and it’s beyond exciting to share this passion with the next generation of young scientists.”

The project will begin to recruit teams from eclipse path communities in this fall. Interested parties can find more information and a contact form on the project’s website, https://eclipse.boulder.swri.edu.

Courtesy of SwRI/Citizen CATE 2024/Dan Seaton

Through the Citizen CATE 2024 project, SwRI’s Dan Seaton produced this false color, polarized image of the solar corona during the 2023 total solar eclipse viewed from Exmouth, Western Australia.

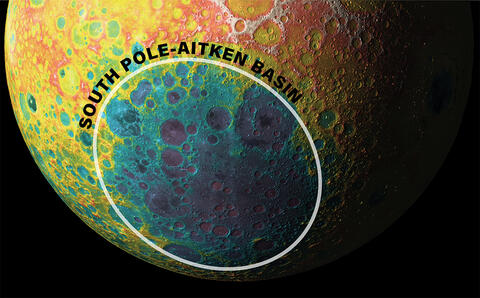

SwRI to Lead NASA/SSERVI Center for Lunar Origin and Evolution

Southwest Research Institute has entered into a five-year, $7.5-million cooperative agreement with NASA to lead the Center for Lunar Origin and Evolution (CLOE). The Solar System Exploration Research Virtual Institute (SSERVI) center will support enabling science for human exploration of the Moon as well as the Endurance-A mission concept, a far side lunar rover mission prioritized by the 2022 Planetary Science and Astrobiology Decadal Survey report.

“The Moon is unmatched in its potential to provide fundamental advances in our understanding of the origin and early evolution of the solar system,” said SwRI’s Dr. William Bottke, CLOE principal investigator. “Human exploration of the Moon revolutionized lunar science in the past and promises to do so again in the near future.”

Apollo samples from the lunar nearside provided the foundation for current knowledge of the Moon’s composition, crust and bombardment up to 4 billion years ago. But the earliest history of the Moon in its first 500 million years remains less well understood. NASA’s Artemis Program will send humans back to the Moon starting in the mid-2020s with landings in the south polar region. Exploration of the more ancient lunar far side will reveal the preserved record of the earliest bombardment of the Moon, including the oldest and largest impact basin. The ancient 1,500-mile-wide South Pole-Aiken (SPA) basin extends from near the South Pole to cover much of the far side’s southern hemisphere.

The far side of the Moon is the hemisphere that always faces away from Earth because of the Moon’s synchronous rotation. Compared to the near side, the far side terrain is rugged, with a multitude of impact craters and relatively few of the large, dark basaltic features characteristic of the nearside.

“Exploring the Moon has tremendous potential for supporting transformative science,” said CLOE Deputy Principal Investigator Dr. Robin Canup, vice president of SwRI’s Solar System Science and Exploration Division. “Models indicate that the Moon formed via a titanic collision with the Earth at the end of our planet’s formation. Clues needed to unravel the nature of this event are still on the Moon and can help us better characterize terrestrial planet formation.”

CLOE will focus on models of terrestrial planet formation and early lunar bombardment, the conditions of Earth-Moon origin, and how exploration of the SPA basin can allow us to better understand solar system formation and early evolution. Because the impact that formed SPA was so large, it almost certainly excavated material from the Moon’s deep interior. Collecting samples of these materials would significantly expand knowledge of the Moon’s bulk composition and subsurface volatile content — key data needed to reveal the conditions of the Earth-Moon origin and the thermochemical evolution of a young rocky world.

“The time is ideal for SSERVI — a program designed to work at the interface of NASA’s robotic scientific and human exploration programs — to play a central role in supporting and maximizing the scientific return from planned lunar exploration,” Bottke said. “The envisioned Endurance-A robotic rover would traverse SPA and collect carefully selected samples to be delivered to Artemis astronauts for return to Earth, producing an Apollo-class sample set from the far side of the Moon.”

Courtesy of NASA/Goddard

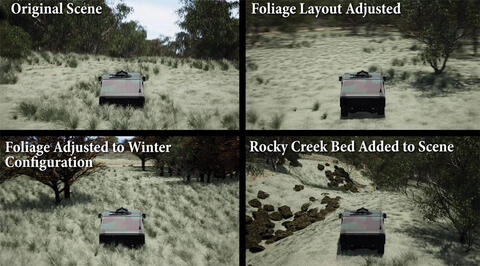

Simulating Off-Road Environments to Test Connected, Automated Vehicles

SwRI has created a 3D simulation tool to test automated vehicles in virtual off-road environments modeled after real-world conditions. The research expands SwRI’s investment in software-in-the-loop solutions to test connected and automated vehicles (CAVs) in scenarios ranging from congested roadways to off-road terrain.

SwRI’s Simulation Scene Adjustment Tool evaluates automated vehicles in 3D simulations of off-road environments. The image shows 3D scenes featuring different ground cover, simulating grass, foliage or rocks to virtually test military automated ground vehicles (AGVs).

SwRI demonstrates AGVs traversing real-world terrain after virtual testing using its Simulation Scene Adjustment Tool.

A simulated 3D environment supports evaluations of large numbers of scenarios that would be cost-prohibitive to test in the real world. The technology meets U.S. Department of Defense demands for modeling and simulation tools to help advance the development of automated ground vehicles (AGVs).

SwRI used internal funding to develop a “pipeline” of technology with custom algorithms, off-the-shelf software, open-source tools, and publicly available map data. The project developed a “Simulation Scene Adjustment Tool” with a 3D video-game-style interface to test virtual ground vehicles on off-road terrain. The simulator also creates a digital twin, a virtual representation of an automated vehicle that looks and behaves like its counterpart in the real world.

“Simulation with the digital twin is crucial for AGV testing and development,” said Joe Auchter, who led the research for SwRI’s Intelligent Systems Division. “Our Simulation Scene Adjustment Tool allows a user to push AGVs to their limits and explore ‘what-if’ scenarios in a variety of simulated environments more rapidly, safely and cost-effectively than real-world testing allows.”

SwRI’s simulator consists of a graphics engine, dynamics engine, vehicle modeling tools, vehicle terrain interaction models and plug-ins to communicate with an autonomy software stack. It builds scenes with geographic information system (GIS) data such as digital elevation models (DEMs) from aerial scans conducted by the San Antonio River Authority and other government agencies.

“We developed algorithms to generate synthetic environments from user-configurable GIS data such as DEMs,” Auchter said. “This allows us to build simulated test environments that share relevant characteristics with real geo-specific locations where vehicles will eventually operate.”

SwRI’s computer models simulate computer vision and sensing outputs for lidar, radar, cameras, GPS and other subsystems that provide data for AGV navigation and path planning systems. A dynamics engine simulates forces caused by gravity and motion as the vehicle model moves through the 3D environment. Simulated vehicles can be programmed with weight, speed, horsepower, center of gravity and other realistic characteristics. A graphics engine simulates trees, grass, terrain, objects and visual effects such as sky and clouds.

SwRI has made safety and security a priority in the development of autonomous vehicles and automated driving systems as the technology reaches advanced levels of readiness for civilian and military use.

“If you look at field testing of automated vehicles, there are simply not enough miles or novel situations that you can throw at a vehicle to encounter all the edge cases for sensors and software,” said Jerry Towler, assistant director of SwRI’s Robotics Department. “Modeling and simulation help test AGVs and Advanced Driver Assistance Systems to enhance safety and ensure capability before and alongside deployment into real-world testing environments.”

NASA Center Focusing on Additive Manufacturing

SwRI is contributing to a new NASA institute to improve understanding and enable rapid certification of metal parts created using advanced additive manufacturing (AM) techniques. The Institute for Model-based Qualification & Certification of Additive Manufacturing (IMQCAM) will work to improve computer models of additively manufactured metal parts and expand their utility in spaceflight applications.

Additive manufacturing uses 3D printing or rapid prototyping to build an item by layering plastic, metal and other materials using a custom computer-generated design. Because AM creates sturdy components with intricate design qualities, it appeals to a wide range of users, including the aerospace, medical and manufacturing industries.

IMQCAM is one of two new Space Technology Research Institutes (STRIs) created by NASA to develop technology in critical engineering and climate research arenas. NASA began creating STRIs to strengthen its ties to the academic community through sustained investment in the development of research and technology crucial to NASA’s future.

Over the course of five years, this STRI will develop detailed computer models, or digital twins, for additively manufactured parts that have been validated against experimental data and subjected to rigorous uncertainty quantification protocols. The models will evaluate the fatigue response of spaceflight materials currently used for 3D printing, as well as introducing and qualifying new materials.

SwRI will aid in technology transfer of university-developed models for practical industrial use. This process will include integration with the SwRI-created DARWIN® (Design Assessment of Reliability with INspection) fracture mechanics and reliability assessment software, which supports damage-tolerant design and analysis of metallic structural components. The new IMQCAM is led by Carnegie Mellon and Johns Hopkins universities.

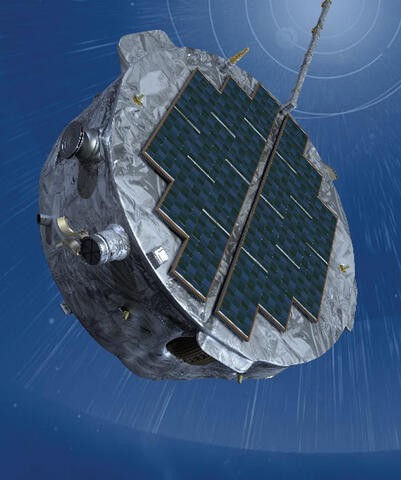

IMAP on Track for 2025 Launch

NASA’s Interstellar Mapping and Acceleration Probe (IMAP) mission has completed its Mission Critical Design Review and is on track to meet its scheduled 2025 launch. IMAP will study the interaction between the solar wind and the interstellar medium as well as the fundamental processes of particle acceleration in space. In addition to managing the payload office, SwRI is providing IMAP’s Compact Dual Ion Composition Experiment (CoDICE) instrument and supporting other instrument teams.

“IMAP will help us gain a greater understanding of how our heliosphere interacts with the interstellar medium, providing a better understanding of our place in the galaxy,” said Susan Pope, director of SwRI’s Department of Space Instrumentation and IMAP’s payload manager.

Courtesy of NASA/Johns Hopkins APL/Princeton University

IMAP will help researchers better understand the boundary of the heliosphere, a sort of magnetic bubble surrounding and protecting our solar system, where the constant flow of particles from the Sun, called the solar wind, collides with material from the rest of the galaxy. This bubble limits the amount of harmful cosmic radiation entering the heliosphere. IMAP instruments will collect and analyze particles that make it through.

The CoDICE instrument, initially developed with SwRI internal funding, combines the capabilities of multiple instruments into one patented sensor. CoDICE will measure the distribution and composition of interstellar pickup ions, particles that make it through the “heliospheric” filter. It will also characterize solar wind ions as well as the mass and composition of highly energized solar particles associated with flares and coronal mass ejections.

SwRI is a key member of the teams for other payload instruments, responsible for the detector on IMAP-Hi and the conversion subsystem on IMAP-Lo. SwRI is also building high-voltage power supplies for the Solar Wind Electron (SWE) and the Global Solar Wind Structure (GLOWS) instruments and providing digital electronics for four IMAP instruments.

SwRI Pursues Next-Generation NOAA Coronagraph

NASA has selected SwRI for a Phase A study to develop the Space Weather Solar Coronagraph (SwSCOR) on behalf of the National Oceanic and Atmospheric Administration (NOAA). NOAA’s Space Weather Next Program is charged with providing critical data for its space weather prediction center. SwRI is one of five organizations developing a definition-phase study to produce the next-generation NOAA L1 Series COR instrument to detect and characterize Earth-directed coronal mass ejections (CMEs).

CMEs are huge bursts of coronal plasma threaded with intense magnetic fields ejected from the Sun over the course of several hours. CMEs arriving at Earth can generate geomagnetic storms, which can cause anomalies in and disruptions to modern conveniences such as electric grids and GPS systems. Coronagraphs are instruments that block out light emitted by the Sun’s surface so that its outer atmosphere, or corona, can be observed.

“SwSCOR is a short, externally occulted coronagraph with a novel 1.5-stage occultation scheme that enables darker, wider-field imaging than a single multi-disk occulter alone,” said SwRI’s Dr. Craig DeForest, who is leading the study. “Its design redirects the major source of diffracted stray light formed by the occulter itself. This design enables imaging closer to and/or farther from the Sun than comparably sized instruments with conventional occultation.”

Stray light is the largest challenge of coronagraph design. Coronal structures a few degrees away from the Sun are a billion times fainter than the Sun itself. Current multi-disk occulters cut stray light by many orders of magnitude. Adding more disks yields more occultation but tightens machining and assembly tolerances.

“SwRI is investigating several novel occulter designs,” DeForest said. “Preliminary laboratory experiments with our latest prototype indicate a more than 10-fold improvement over similar-geometry multi-disk designs in use today, while improving manufacturability and alignment tolerances.”

SwRI Researches Faster Spaceflight Technology

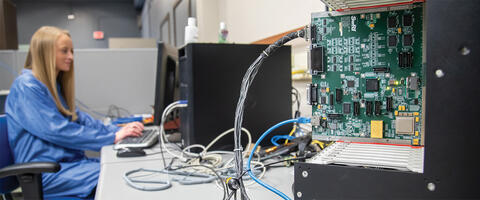

SwRI is evaluating the next generation of fast and reliable microprocessors for embedded spaceflight systems, seeking technology that performs more complex tasks using less power.

“Conventional spaceflight technology is larger, heavier and more power-hungry than today’s microprocessors, which translates to bigger spacecraft, larger solar arrays and more batteries with complex thermal control — all of which can be very expensive to launch,” said Patrick Saenz, a computer scientist in SwRI’s Intelligent Systems Division. “Our latest research is exploring much faster computers with a smaller footprint.”

Using laboratory tests, engineers determined that newer microprocessors built with “instruction set architectures” could outperform conventional spaceflight technology under certain configurations. The research opens the door to embedding space systems with the same microprocessors used in cell phones and other Earth-based electronics.

The team first evaluated open-source reduced instruction set computers (RISC-V or “risk five”). Among other findings, researchers determined that some space-ready circuits, known as Field Programmable Gate Arrays (FPGAs), were incompatible with faster RISC-V soft-core processors. Other FPGAs, however, successfully operated with RISC-V and even outperformed conventional processors. Then SwRI evaluated the performance and power consumption of an Advanced RISC Machines (ARM) processor. The ARM processor outperformed a legacy processor with more than five times the processing power, using a fraction of the energy.

“The dynamic power management features offered by the ARM processor can provide finer tuning of power utilization throughout a mission’s lifetime,” said Kayla Henderson, an SwRI embedded systems software engineer.

RISC-V and ARM technology can also improve software development, reuse and interoperability for space missions.