Background

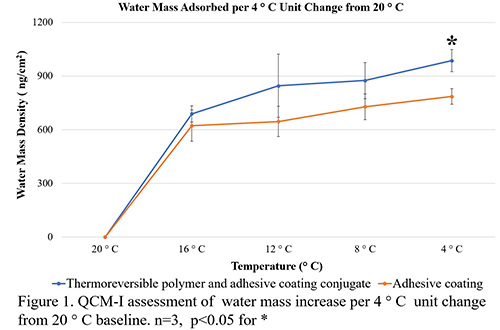

Figure 1: QCM-I assessment of water mass increase per 4°C unit change from 20°C baseline.

Recombinant adeno associated virus (rAAV) is a vector readily used in the biopharmaceutical industry for use in genetic modification of target cells and vaccine production. The current transfection methods for production utilize forward transfection (FT), which involves first adding cells for adherent or suspension culture and subsequently adding a DNA plasmid mix containing genetic instructions for production of rAAV vector. Both FT methods are limited by scalability (adherent) and transfection efficiency (suspension).

We proposed a novel surface coating platform technology that circumvents the limitations of current methods. The coating is designed to use temperature controlled solid-phase reverse transfection (RTF), which involves first adding plasmid to a surface, then adding cells on top of adsorbed plasmid, and finally transfection by plasmid entry into overlying cells. RTF will be accomplished by using thermoresponsive polymers that dehydrate/shrink and become hydrophobic at temperatures above the lower critical solution temperature (LCST), and at temperatures below the LCST the polymers hydrate/swell and become hydrophilic. Such a coating would greatly reduce costs for production of viral vector, improve efficiency of transfection, and facilitate manufacturing for other cell and gene therapy applications.

Approach

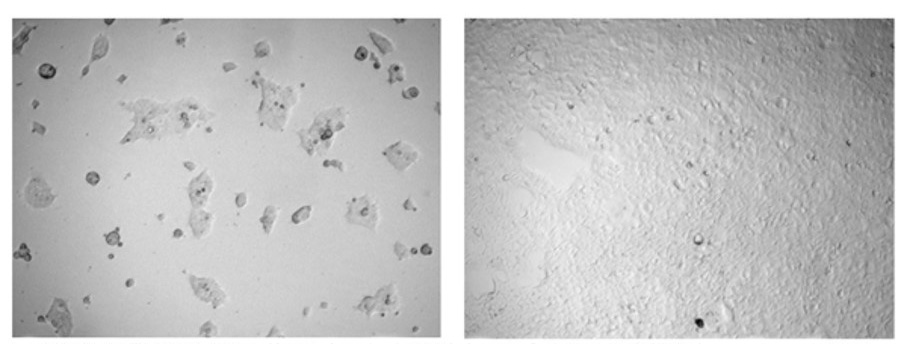

The approach involves first fabricating a thermoreversible surface coating, comprised of a thermoreversible polymer conjugated to an adhesive coating, that permits culture of overlying HEK293-FT producer cells. The fabrication and thermoreversibility is characterized by quartz crystal microbalance with impedance (QCM-I) studies that show significant water adsorption and hence transformation to a hydrophilic structure upon cooling to 8-4°C. We are currently working on the formulation of the DNA plasmid thermoreversible polymer carrier (polyplex), that will be immobilized on surface coating before cell seeding, and then released to transfect seeded cells with temperature change to 18°C.

Figure 2: HEK293-FT cells under differential interference contrast (DIC) imaging at 19 hours (left) and at 67 hours (right) after seeding 20,000 cells cm-2 in wells coated with thermoreversible polymer and adhesive coating conjugate. Cells were grown up to 90% confluency

Accomplishments

We have fabricated the surface coating on which the cells will be seeded but are still working on the polyplex formulation and reverse transfection details. The completed device will generate new intellectual property in addition to a recently filed, patent application (U.S. Applied 18/459,576).