Background

On-chip integration of inductors and transformers can enable power converters with high density, high reliability, low cost, high frequency, and low interconnect loss for high-current point-of-load applications. Nevertheless, depositing high-quality magnetic coatings that are back-end-of-line compatible, affordable (fast deposition), and properly tuned for their application remains challenging. Nanocrystalline oxide coatings are promising candidates as core materials due to their low core loss and high saturation flux density. However, the deposition rates of these oxide materials are low, which limit the cost effectiveness. In addition, the magnetic properties of the coatings are strongly dependent on the chemistry and structure of the coatings. The project, supported by SwRI and UT Austin’s Energize program, was established with the collaboration between experts in power electronics and magnetic materials (UT Austin) as well as experts in high-rate deposition of oxide materials (SwRI) to advance on-chip integration of cored magnetic components. The goals of the project are to establish a high-rate reactive magnetron sputtering process for producing CoZrO ferromagnetic coatings, study the coating structure and properties, and demonstrate the feasibility of scaling up the coatings for the fabrication of on-chip magnetic cores.

Approach

A ferromagnetic coating material based on CoZrO previously studied by the UT Austin team was selected as the coating candidate. The SwRI team is establishing a high-rate reactive magnetron sputtering process for depositing CoZrO coatings with desired stoichiometry. Homogeneous and multilayered CoZrO coatings are being fabricated and characterized to establish the correlation between the process, chemistry, microstructure, and magnetic properties of the coatings. Comprehensive modeling and characterization are being conducted by the UT Austin team to provide guidance for optimization of the coatings. At the end of the project, the optimized CoZrO coating is deposited onto large-area toroid cores with SU-8 photoresist with scaled up thickness. The coated cores will be used to fabricate on-chip inductors for core loss evaluation by the UT Austin team.

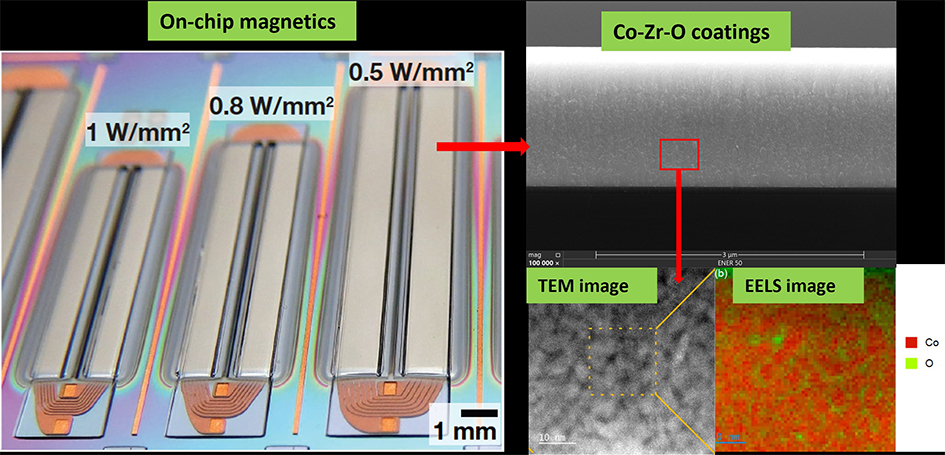

Figure 1: The developed CoZrO magnetic coatings for on-chip magnetic components. The SEM image shows a CoZrO homogeneous coating deposited by the high-rate reactive sputtering process at SwRI. The TEM and EELS images show the coating exhibited a nanocomposite structure in which co-based domains were surrounded by an oxide matrix.

Accomplishments

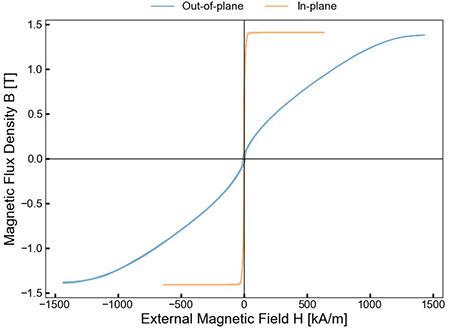

Figure 2: In-plane magnetic hysteresis (M-H) loops of a CoZrO coating measured at room temperature. The coating exhibited the highest saturation magnetizations (Msat) of 1.4 T and a low coercivity (Hc) of 12.

A high-rate deposition process for depositing CoZrO coatings has been successfully developed at SwRI. A close-loop reactive gas (O2) partial pressure control system has been integrated into the sputtering process to achieve high deposition rates and precise control of the coating chemistry. The deposition rate of the developed coating process was six times higher than what was reported in earlier literature. The optimized CoZrO coatings exhibited a nanocomposite structure in which Co-based domains were surrounded by an oxide matrix (CoOx and ZrOx), as shown in Figure 1. The CoZrO coatings with such unique microstructure exhibited excellent ferromagnetic properties with the highest saturation magnetizations (Msat) of 1.4 T and a low coercivity (Hc) of 12, as shown in Figure 2. These values outperformed the CoZrO coatings shown in early literature. The thickness of the optimized CoZrO coating technology has been successfully scaled up to 28 µm and deposited onto toroid cores with SU-8 photoresist. The coated cores will be used to fabricate on-chip inductors for core loss evaluation by the UT Austin team in the near future.