Background

Conversion surfaces have been extensively used in the space industry. They are applied to plasma particle instruments and calibration facilities to enable the detection of neutral atoms through surface-ionization, e.g. conversion to ions or release of secondary electrons. The conversion surfaces are typically extremely smooth (with surface roughness less than 10 angstrom (Å)) to assure high conversion efficiency, prevent secondary scattering of the surface, and keep the properties of the incident particles unchanged. In 2022, SwRI established a coating technology to produce ultra-smooth (subsurface roughness ~3.3 Å) and ultra-thin (film thickness ~45 nm) diamond-like carbon (DLC) films as the conversion surfaces for the Interstellar Mapping and Acceleration (IMAP) mission. In this Targeted IR&D project, we aimed to develop ultra-smooth cadmium telluride (CdTe) and zinc selenide (ZnSe) thin films as new conversion surfaces for space instruments. CdTe and ZnSe thin films have been considered as novel conversion surface materials with potential of reducing angular scattering of the incident beam and thus increasing efficiency of the conversion surfaces. The goal of the project was to achieve an optimized coating technology/process these two materials with quality comparable or better than DLC films provided for the IMAP-Lo instrument.

Approach

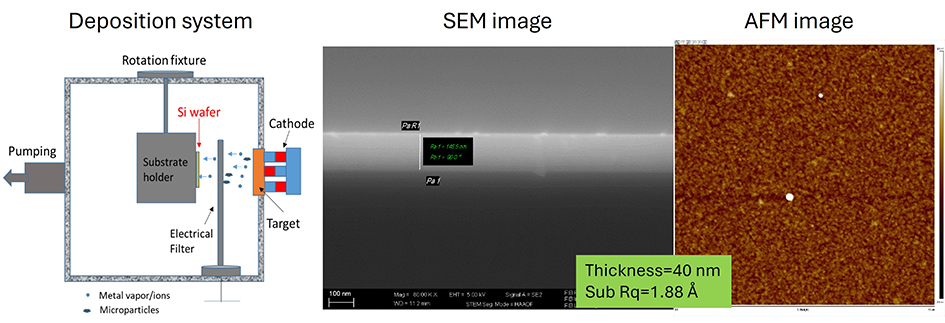

The coating development was carried out in a magnetron sputtering system using radio frequency (RF) magnetron sputtering. Ultra-smooth silicon (Si) wafers (surface roughness less than 5 Å) were used as substrates for the film development. Before film depositions, Si wafers were precisely cleaned using wet and dry cleaning protocols to ensure the surface is particulates-free. The surface roughness of the films was measured by atomic force microscopy (AFM). The effects of film thickness, working pressure, RF sputtering power, and using an electrical mesh filter on the surface roughness of ZnSe films were studied to determine optimal deposition conditions for producing ZnSe conversion surfaces. Selected ZnSe films were shipped to the University of Bern in Switzerland to measure their conversion efficiency using the Imager for Low Energetic Neutral Atoms (ILENA) facility. The same facility was used for the IMAP-Lo DLC conversion surface measurements.

Accomplishments

We have established an in-house coating technology/process based on RF magnetron sputtering to produce ultra-smooth conversion surfaces from CdTe and ZnSe sputtering materials. The optimized ZnSe films exhibited a minimum sub-surface (surface area free from large particle contamination) roughness (Sub Rq) of less than 2 Å, as shown in Figure 1. The preliminary results from conversion efficiency measurement showed that an 80 nm thick ZnSe film with a sub Rq of 2.2 Å exhibited comparable conversion efficiency to the 45 nm DLC conversion surface with the surface roughness of ~3.3 Å. It is expected that a thinner ZnSe conversion surface (e.g. 40 nm) with a sub-surface roughness of less than 2 Å may show further improved conversion efficiency. Furthermore, employing a thicker conversion surface in space instruments may enhance their durability against energetic bombardment from incident particles.

Figure 1: Schematic drawing of the radio frequency magnetron sputtering system and scanning electron microscope and atomic force microscopy images of a 40 nm ZnSe thin film showing a surface roughness of 1.88 Å.