Background

The Hydrogen Industry Testbed Scoping Study (HITSS) Research Initiative PDIR was initiated to identify high-potential research needs of our customers in the hydrogen technology industry and design three to five hydrogen test facilities to meet those research goals. Upon completion of the project, a conceptual design of each facility will be documented, including the customer needs, facility capabilities, potential revenue generation, and potential funding mechanisms for facility fabrication.

Approach

To accomplish this objective, the HITSS program was created to lead and manage up to three discrete hydrogen testbed facility design projects. First, a request for proposals was submitted internally seeking cross divisional project ideas. After careful consideration, two projects were selected from eight total submissions. The projects, which are both collaborations between Divisions 1 and 18, are summarized below.

Hydrogen Energy Technology Center (H2ETC)

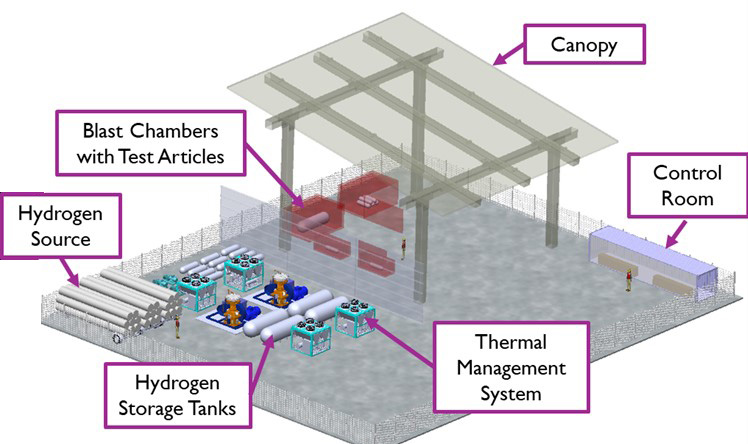

This team’s facility includes cryogenic liquid and high-pressure gas hydrogen flow loops feeding specialized environmental and blast containment test chambers to evaluate hydrogen components and systems.

Metering Research Facility – H2 Generation & Blending into Natural Gas Evaluation Study (MRF-HINGES)

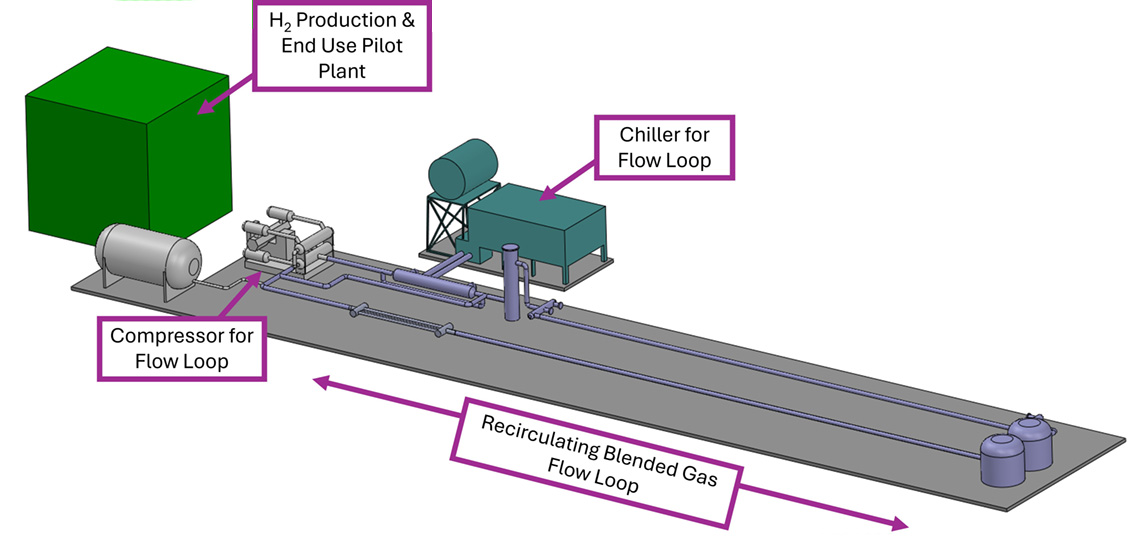

This team’s goal is to upgrade the Metering Research Facility to be a blended-gas (natural gas/hydrogen) test facility for components such as flow meters, as well as hydrogen processes such as small-scale hydrogen production, blending, and separation. This facility capitalizes on existing equipment to gain value with minimal investment.

Both projects followed a rigorous schedule, documenting customer needs and designing a hydrogen test facility, while learning from each other in a team atmosphere.

Accomplishments

The teams completed the designs of their facilities and created a plan for implementation that relies on a staged approach. Both facilities have near-term revenue generation possibilities with a small capital investment. The facilities are then planned to grow in size and capabilities in the coming years with a mix of federal funding, commercial funding, and additional capital investment.

Figure 1: The Hydrogen Energy Technology Center (H2ETC) allows for 100% hydrogen gas performance and validation testing of flow components and prime movers at high temperature and pressure. The conceptual design shown here would be fabricated at a new test site on SwRI’s campus.

Figure 2: The H2 Generation & Blending into Natural Gas Evaluation Study (MRF-HINGES) team designed the Center for Hydrogen and Natural Gas Evaluation (CHANGE) facility to mimic the hydrogen lifecycle, from hydrogen production, through distribution, to end use. The conceptual design shown here would be implemented at SwRI’s Metering Research Facility.