Background

In response to the Hydrogen Industry Testbed Scoping Study (HITSS), representatives from Divisions 01 and 18 collaborated to explore the design requirements and market viability of a high-pressure and cryogenic liquid hydrogen test facility at Southwest Research Institute (SwRI) to provide integrity testing of components and systems. The test facility is entitled the Hydrogen Energy Technology Center (H2ETC), which encompasses the hydrogen industry we hope to serve but also allows for future flexibility of the facility.

Approach

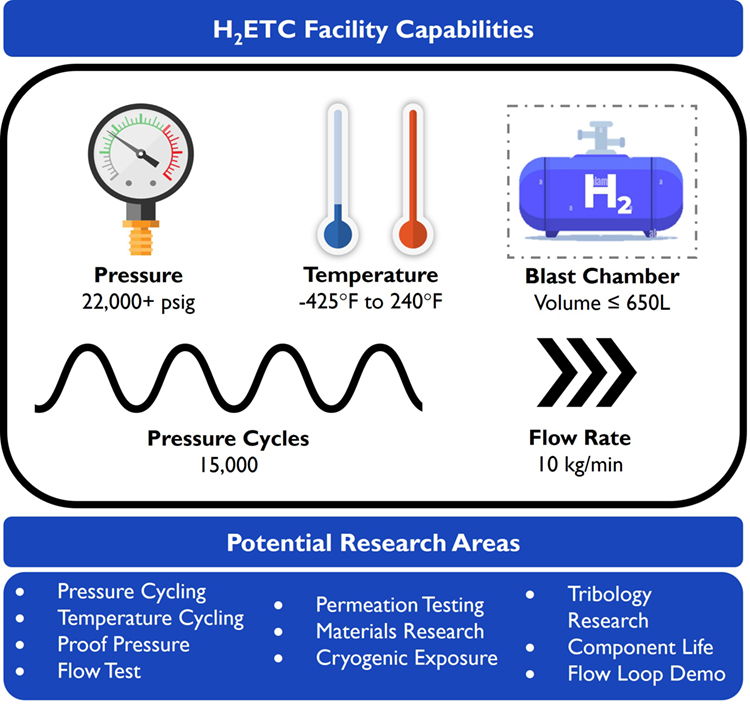

To accomplish this objective, the H2ETC project team gathered data from over 50 companies to better understand current and projected industry demands. In recent years, SwRI has seen a dramatic increase in hydrogen-related inquiries for testing that were beyond our current capabilities. These inquiries provided the team with an initial understanding of industry needs and were the basis for the team’s application to HITSS. Throughout the project, the team refined the facility’s capabilities by soliciting feedback from industry contacts through a survey the H2ETC team created, reviewing relevant codes and standards, and evaluating the capabilities of current competitors.

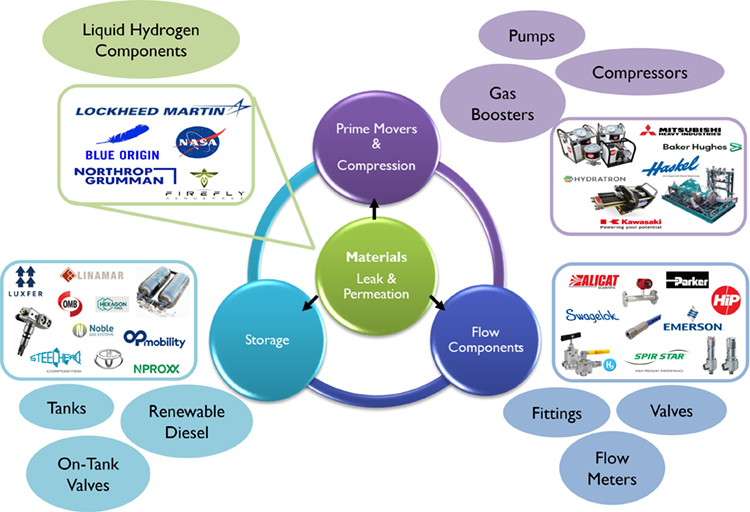

Based on industry feedback and market research performed during this project, the project team defined the capabilities of the full-scale H2ETC test facility that will incorporate both the cryogenic liquid and high-pressure gaseous hydrogen flow loops and specialized test chambers. The project team worked with Facilities and ESS to identify a potential location on SwRI’s main campus for the final test facility.

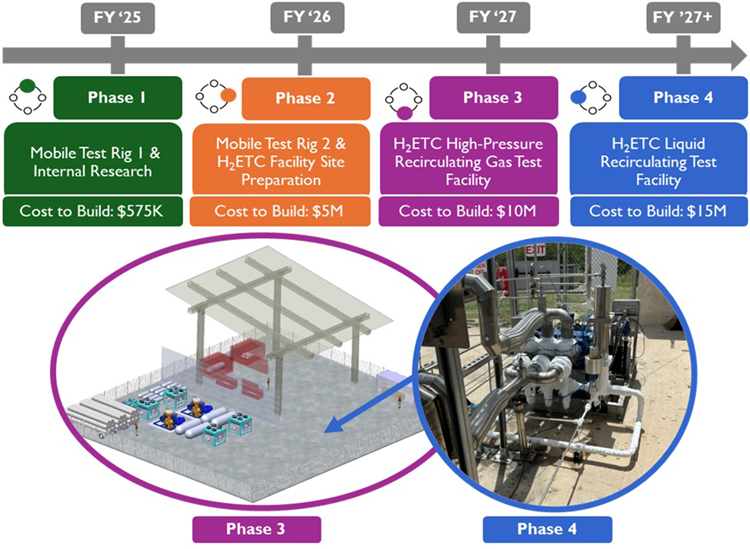

During the course of the project, the team identified that long lead-times and the cost to commission such a facility were prohibitive for direct industry funding. Due to these two main factors, the H2ETC team plans to move forward with this effort in a phased approach that would allow limited performance testing quickly and at a relatively lower cost. Costs for each phase were generated during this project using blast chamber simulations, up-to-date equipment quotes, and engineering estimates.

Accomplishments

Working with a cross-divisional team was instrumental to the project’s success and aided in the professional growth of the team members. The team gained knowledge and understanding of the current hydrogen industry testing needs and used this information to develop a high-level process diagram for the H2ETC. Safety considerations for the facility were also investigated including the selection of blast chambers sized for the appropriate test article volumes and pressures. The team outlined a phased implementation approach by incrementally building upon capabilities to enable projects quickly with minimal capital investment, decrease the lead time to provide meaningful service to our clients, and expand technical experience of the SwRI project team. Cost estimates for the facility design, fabrication, and commissioning were refined for the entire facility build as well as incremental build phases. With a phased approach, the team expects that near-term revenue generation will help recover capital investments in a shorter time period with multiple funding strategies including commercial funding, government funding, and contingency capital.

Figure 1: A phased approach allows for incremental expansion of scope, experience, and funding of the H2ETC facility. Inset pictures show a 3D rending of Phase 3 of the H2ETC High-Pressure Recirculating Gas Test Facility, as well as a picture of SwRI’s current liquid hydrogen pump system, which is a representation of the type of equipment included in the Phase 4 facility.

Figure 2: There are three main hydrogen component categories identified, and examples of components and potential customers are provided for each category. Components are made from materials that need to be evaluated for compatibility, leak, and permeation, especially for cryogenic liquid hydrogen in the aerospace industry.

Figure 3: The H2ETC facility will cover a wide range of test capabilities for high-pressure hydrogen gas and cryogenic liquid hydrogen. These capabilities were designed from surveying the industry testing needs and the current state-of-the-art. The H2ETC facility will aid in various research areas such as pressure cycling, permeation testing, and endurance testing of hydrogen components and systems.