Background

Low-temperature combustion (LTC) concepts can demonstrate higher engine efficiencies than traditional pre-mixed spark-ignition combustion modes. Most LTC concepts, however, are extremely sensitive to slight changes in inlet temperature, pressure, or composition, posing challenges for practical application and transient control. One relatively new combustion strategy known as Spark Assisted Compression Ignition (SACI) leverages the use of conventional spark-ignited flame propagation to trigger low-temperature compression ignition as an additional degree of freedom for better combustion control against the noise factors encountered in production applications. Prior simulation results suggested that some of the shortcomings of the SACI combustion mode such as high ringing in the cylinder at moderate loads and load limitations could be overcome by combining it with reformed exhaust gas recirculation (EGR) referred to as dedicated-EGR (D-EGR) when used in conjunction with H2. In this project SACI combustion mode was explored in combination with a H2-rich D-EGR strategy by modifying an existing light-duty single cylinder research engine (SCRE). In a traditional D-EGR setup the amount of EGR and H2 are intrinsically linked, most commonly at 1% H2 and 25% EGR per cylinder. In this IR, the test was setup so the amount of H2 and EGR could be varied independently.

Approach

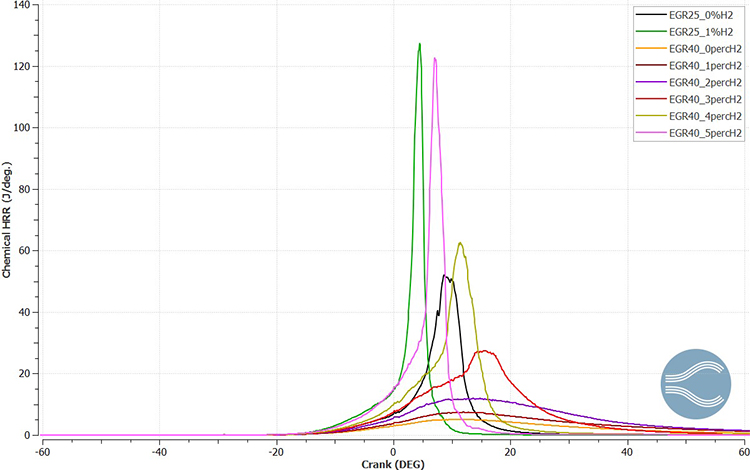

An initial concept evaluation was carried out as a part of the prior Presidential Discretion IR project R8988. The study was limited to CFD modeling of the process in a PSA EB2 1.2 L engine with a modified compression ratio (CR) of 17:1 which demonstrated that there was a potential for engine efficiency improvement over the baseline operating with SACI + EGR. The CFD results confirmed the viability of SACI under EGR dilute conditions in the presence of H2. More specifically, it was shown that the heat release rate for a 25% EGR, 0% H2 case was similar to a 40% EGR, 4% H2 case for a 2000 rpm 6 bar BMEP (brake mean effective pressure) test condition with faster combustion at lower EGR percentages (ref Figure 1). Because the SCRE in this project was limited to a 13.7:1 compression ratio (CR), the intake temperature of air, EGR & H2 was heated to 80 °C to simulate the CR difference. The increased intake temperature matched the top dead center temperature and pressure conditions simulated with the higher compression ratio. The quantity of H2 and EGR was swept at 2000 rpm and 6 bar gross indicated mean effective pressure (gIMEP).

Figure 1: Heat release rate expressed as a function pf engine crank angle for 25% EGR case with 0 and 1% H2, and 40% EGR case with 0 – 5% H2.

The following objectives were laid out for this targeted IR project.

- Demonstration of engine efficiency improvement using SACI + traditional D-EGR combustion mode over baseline.

- Identify the minimum H2 required for varying EGR rates at different loads to run SACI + EGR + H2 mode.

- Patent the combustion process and publish results for the promotion of SwRI’s capabilities.

Accomplishments

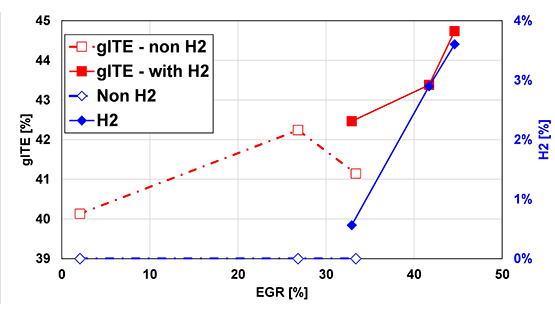

The SCRE was first operated in a traditional SI combustion mode with EGR and H2 to establish a baseline. The gross indicated thermal efficiency (gITE) results are shown in Figure 2. The results show that the engine was unstable at 33% EGR in absence of any H2. Upon introduction of H2, the engine stability and gITE could be extended further. The max gITE achieved during this testing was approximately 45%.

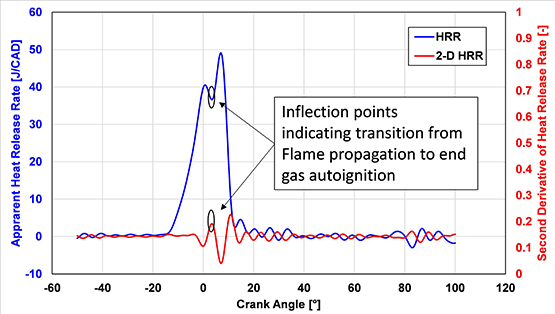

Next, the engine was operated in SACI combustion mode with EGR and H2. The second derivative of the heat release rate was used to determine the percentage of combustion occurring under SACI combustion mode. An example is shown in Figure 3.

Figure 2: gITE and H2 percentage expressed as a function of increasing EGR percentage.

Figure 3: An example of heat release rate (HRR) profile showing SACI combustion and the second derivative of the HRR showing inflection point at the transition between flame propagation and compression autoignition.

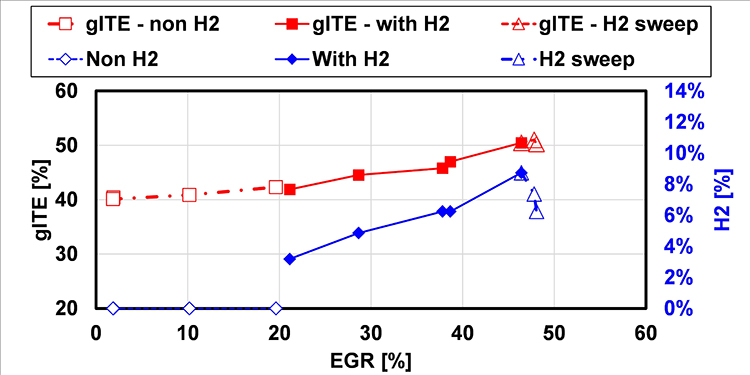

The gITE expressed as a function of increasing EGR and H2 percentage is shown in Figure 4. Surprisingly, gITE greater than 50% was achieved during this sweep at the highest EGR percentages tested at this condition. This was one of the key results from this IR project. This result also made a case for incorporating this combustion strategy into the HEDGE V consortium toward achieving the lofty goal of 50% brake thermal efficiency (BTE).

Figure 4: gITE and H2 percentage expressed as a function of increasing EGR for 2000 RPM 6 bar GIMEP SACI test condition.