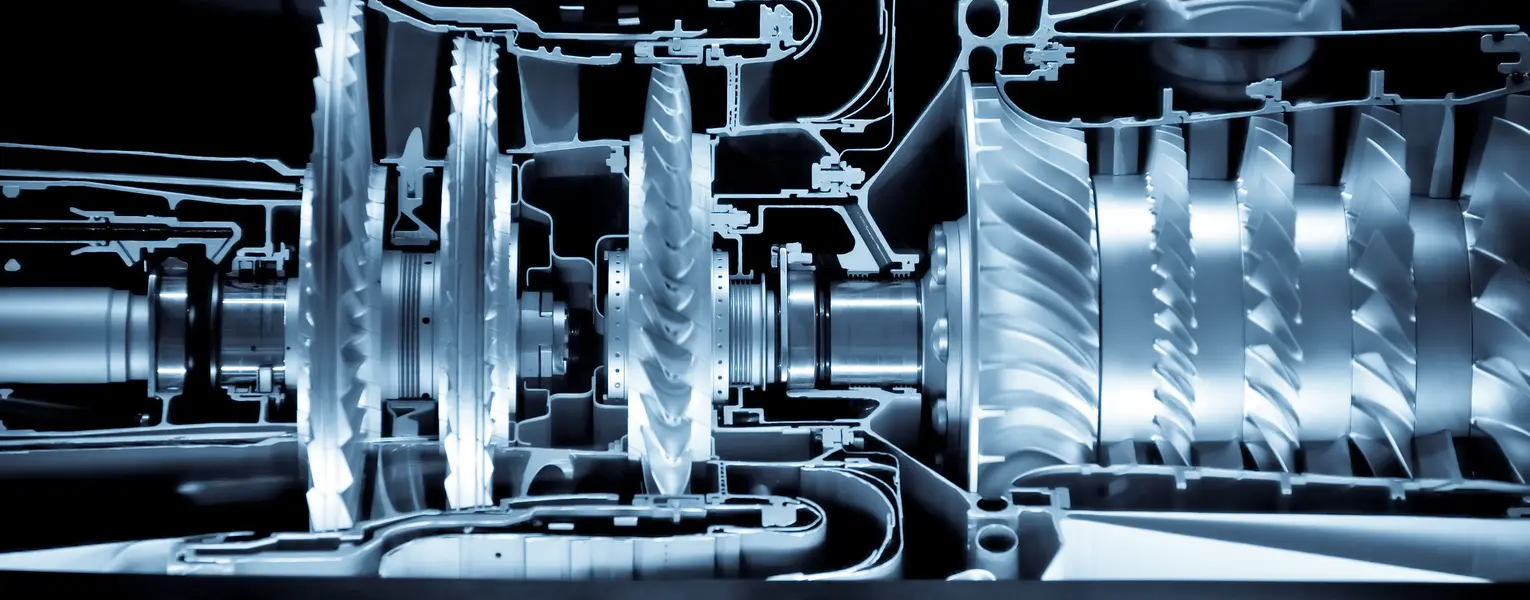

Fluid dynamics, heat transfer, combustion, and fluid-structure interaction are essential disciplines to the effective design, application, and performance evaluation of gas turbines. Southwest Research Institute (SwRI) maintains a variety of commercial and SwRI-developed analysis and computational codes to meet specific needs. A number of flow facilities are used in conjunction with computational methods to support simulation and understanding of fluid flows and their interactions with structures. Flow visualization techniques enhance this capability.

Flow facilities include:

- High pressure (2,500 psi), large volume (980 ft3) N2 gas blowdown system

- Low pressure (2 to 200 psia) air and inert gas recirculating loop to 8 MMSCFD

- Low pressure (to 200 psia) natural gas recirculating loop (to 6 MMSCFD)

- High pressure (to 1,400 psi) natural gas recirculating loop (to 165 MMSCFD)

- 0-6,000 gpm low-turbulence water tunnel

- High-pressure, high-flow combustion tunnel

Turbomachinery Test Facility

Our turbomachinery laboratory is set up to conduct detailed research on centrifugal compressors, gas turbines, internal flows, performance, and the onset of problems such as stall, surge, and various shaft and bearing instabilities. Special instrumentation including laser measurements and high-G self-power imbedded telemetry systems for instrument signals are developed and used by SwRI.

Flow Instability

SwRI uses computation fluid dynamics, along with other analysis and 1D modeling, to predict turbine flows, local behaviors, contributions to performance, and the onset of stall, surge, flutter, or other instabilities. Blade temperature predictions can be made with various degrees and types of cooling as a diagnostic prediction or as a guide to interpreting measurements.

SwRI can offer you a full range of capabilities and experience in rotating machinery technologies including becoming an extension of your engineering department. To contract with SwRI, please contact the Machinery Services Hotline at +1 210 522 3000.

For more information, contact Tim Allison or call +1 210 522 3561.