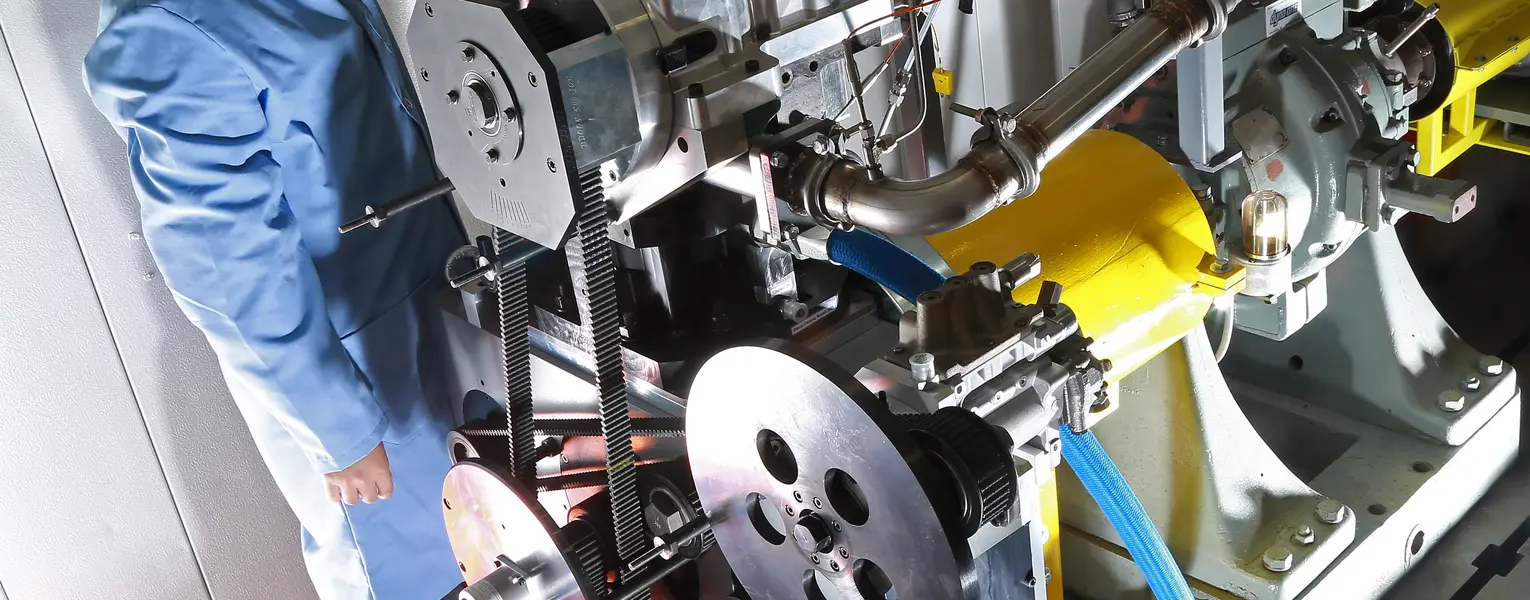

SwRI designed two advanced single-cylinder engine platforms optimized for combustion research and friction analysis. The engines are also designed for alternative fuel, wear, optical, crank offset and bore-to-stroke relationship studies. They are easy to customize to match any desired parent engine, with one platform designed for heavy-duty applications and the other for light-duty applications, and available for contract research projects at SwRI or on site in a client’s laboratory.

Single-cylinder engine testing allows researchers to specify and control variables that are not as directly controlled in multi-cylinder engines. Examples include: the ability to specify boost-to-back pressure ratios, controlling the amount of exhaust gas recirculation seen by the cylinder, controlling the local air-to-fuel ratio within the cylinder and removing some variables that may add complexity or unknowns to multi-cylinder engine tests. An important example is that of intake and exhaust pulse dynamics and especially cylinder-to-cylinder interactions.

The result is simpler, more efficient and lower cost testing, including:

- In-cylinder and combustion analysis

- Friction testing

- Thermal analysis

- Further access to the cylinder allows better thermocouple placement (both quantity and location) than can be achieved on a multi-cylinder engine

- Templug testing

- Controlled air handling experiments

- Open-cycle thermodynamic studies

Related Technology

Related Brochure

Or call Christopher Hennessy at +1 210 522 3079.