Inkjet printing methods on 2D surfaces have been a mature technology for many years within the high-resolution printing domain. Today, this technology is being expanded to 3D surfaces via robotic systems. At Southwest Research Institute, a large-scale prototype with industrial inkjet printing heads mounted to a robotic manipulator was developed, enabling digital graphic printing on 3D surfaces. Initially created for the aerospace industry, this inkjet prototype system was developed to apply colored graphics, also known as liveries, to the exterior of commercial aircraft. Since being demonstrated in 2019, SwRI has developed inkjet systems for other markets including automotive and logistics—printing both multi-colored graphics and non-graphical, functional fluids.

Patented Inkjet Printing Technology

SwRI currently has two patents in the space of robotic inkjet printing:

High accuracy inkjet printing – U.S. Patent No. 9,527,275 B1

Printing using an externally generated reference – U.S. No. 10,828,889 B2

How it Works

SwRI’s solution for robotic inkjet 3D printing is comprised of two main components:

The printing system

The localization system

Inkjet Printing System

Over various projects, the printing system has contained different numbers of printheads for printing different numbers of inks. In the system created for the aerospace application, the printing arrangement contained four, two-color printheads for a total of eight inks – cyan, magenta, yellow, black, orange, green, white, and UV fluorescent. The seven main inks in this system allowed for the creation of many different colors, and the UV fluorescent ink allowed for printing markers that are invisible until illuminated with UV light in which case they fluoresce visible light.

The ink is supplied to these printheads from ink delivery units. While these ink delivery units are based on off-the-shelf inkjet printing hardware, their operation is not. When the robot changes position or orientation, the head pressure from the ink delivery units to the printheads changes, creating the need to dynamically control the ink pressures. If the robot makes a motion and the ink delivery systems do not adjust their pressures, ink may drip from the printhead, or air may be pulled into the ink channels—both of which can be detrimental to the printing process.

Robotic Localization System

The localization system utilizes CAD-to-path and Scan-N-Plan™ capabilities, allowing for automated manipulation of printing hardware. A closed-loop control system of cameras, distance sensors, and accelerometers work with fluid control algorithms to accurately locate the printer to the 3D surfaces.

The localization system comes into play because of a discrepancy between robot accuracy and the accuracy required for the proper placement of the printed droplets of ink. While robot accuracy is improving to levels that are sub-millimeter, the positional accuracy required for inkjet printing is on the order of 0.1 mm at most. The localization system relies on cameras, accelerometers, and laser distance sensors to accurately locate the substrate that is being printed on. These sensors control the movements of high-speed, high-accuracy linear stages at the end of the robot arm that make micro adjustments to the position of the printheads while the robot takes care of macro motions. The fluorescent ink mentioned previously comes into play here by allowing a pattern to be printed that is invisible under normal circumstances, but visible to a camera when illuminated with UV light. This pattern can be used to align the robot to the substrate being printed on.

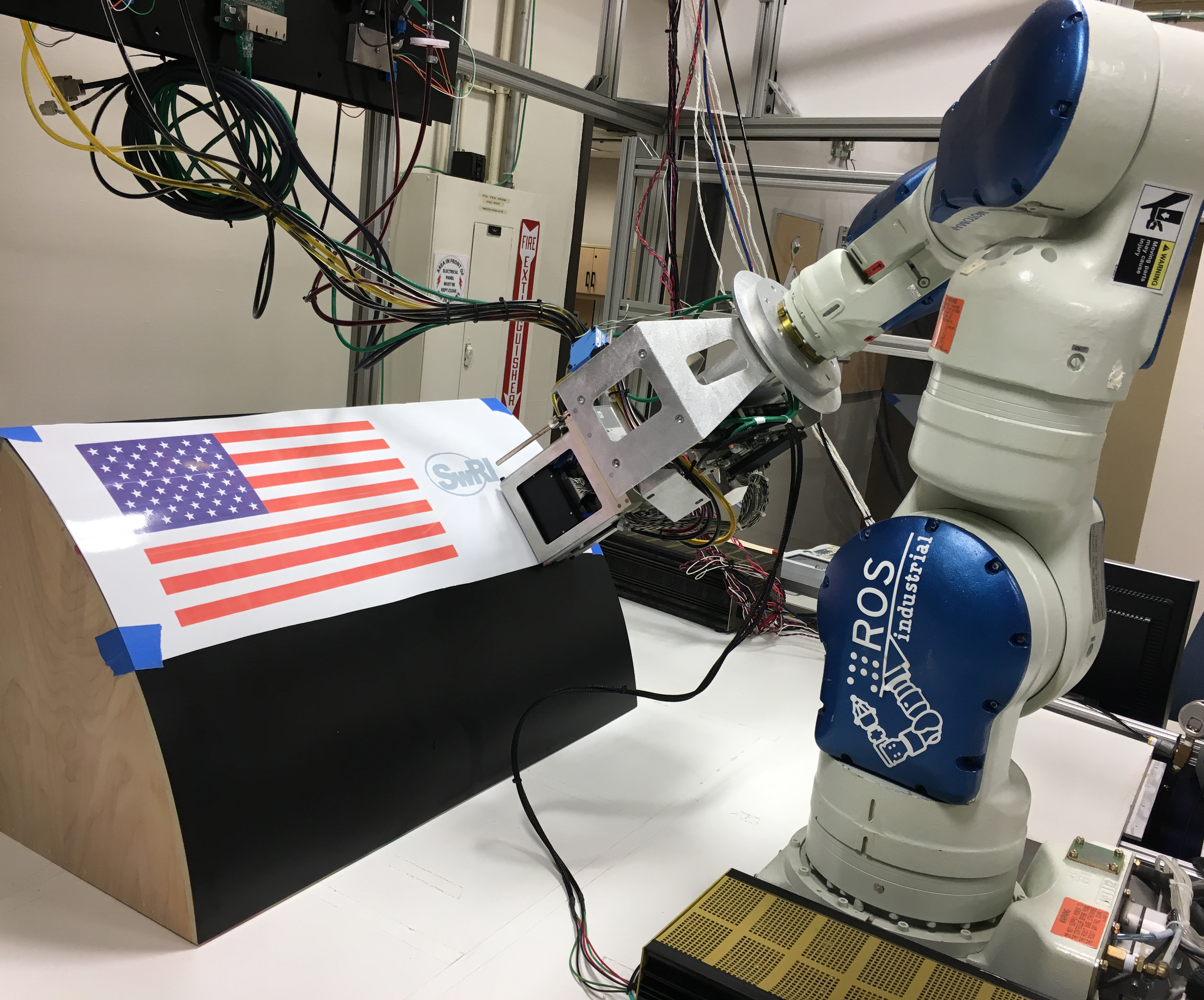

Both the printing and localization system are mounted on the end of a robot arm. In various projects SwRI has worked on, the robot has been programmed using automatic CAD-to-path or scan-to-path capabilities of ROS (Robot Operating System), an open-source software framework for programing robots.

SwRI has patented a large-scale robotic technique for inkjet printing intricate graphics on aircraft and other complicated surfaces, shown here in a laboratory-scale demonstration.

Fields of Use

There are numerous advantages to using ink rather than paint or other graphic application methods. First, inkjet allows for the creation of many different colors in a single pass of the print system whereas painting requires masking, the application of a single color at a time, and dry time. Ink is also lighter than paint, reducing the overall application weight, which in the case of an aircraft saves fuel. Not to mention, environmental requirements for inkjet printing are much less than those for painting, meaning less processing time and reduced facility construction and maintenance costs. Durability is a key advantage of inkjet over the use of techniques such as stickers and vinyl wrapping used in industries such as automotive and construction equipment. Ink is also commonly applied to materials such as glass, metal, and textiles. In these applications, inkjet can provide a quality improvement over traditional painting and screen-printing techniques and can even allow for gray scaling, or a gradient, which is not easy using traditional methods.

Inkjet printing technologies are also useful for “functional fluids” that can be jetted through a printhead. These functional fluids are not for aesthetics, but may provide UV protection, act as a barrier between two materials, alter material properties, or act as an adhesive. One specific functional fluid that is of high interest is conductive ink that can be used to create a conductive trace, essentially a near flat wire, directly onto a surface. The addition of robotics allows for circuits to be applied directly to three-dimensional products such as automobiles and aircraft, reducing the weight and volume of traditional wires.

Inkjet printing is a versatile technology that has applications in many industries. Coupled with robotics, inkjet printing can add to many manufacturing processes by both allowing for the generation of complex graphics and the application of functional fluids.

To learn more, contact Branson Brockschmidt or visit Intelligent Manufacturing & Process Solutions