Background

Piston rings and liners in an internal combustion engine need to seal well to reduce blowby of combustion gasses and maximize the power produced during the combustion of the fuel and air mixture. To do this, they must run-in when new to reach surface finishes that match each other and will last a long time while operating. A softer surface is desirable for running in, but a harder durable surface is required for long term operation. Attempts have been made to put a softer coating on a hard durable coating, but with little success due to delamination. In a previous IR (18-R8381), a hard durable low friction coating was developed using a SwRI-patented coating technology. In this IR, that technology was developed further so that the method could change the recipe of the coating as it neared the end of its deposition, so it changed to a softer coating. In this way, it is the same coating and hence delamination does not occur.

Approach

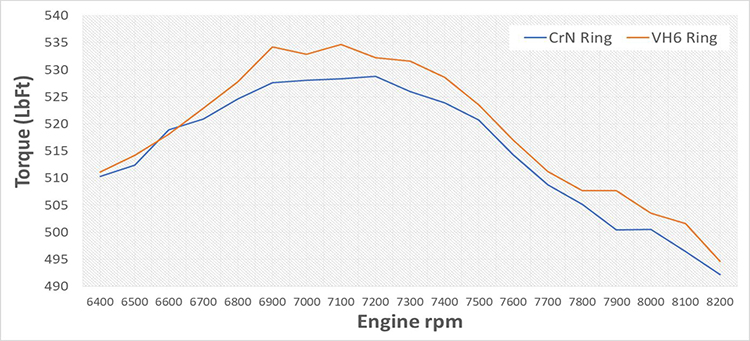

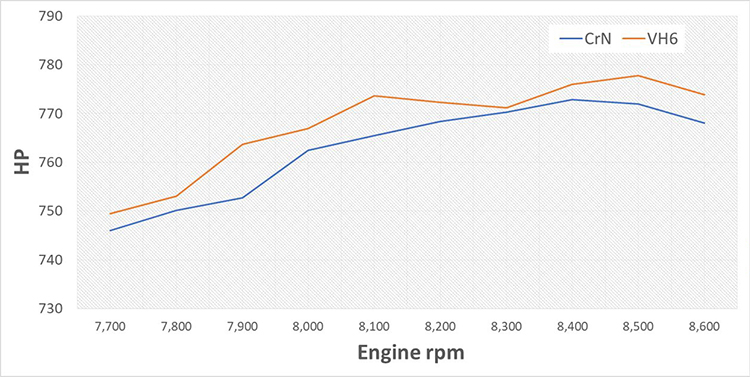

Several different coatings were produced and supplied to the SwRI Tribology group for ring and liner testing. The coating that displayed lower friction and wear than the baseline coating was selected, and this coating was placed on a set of piston rings for a NASCAR engine. The NASCAR engine was placed on the dyno with its baseline rings and then again with the variable hardness coating. The power and torque produced by both sets of rings were compared.

Accomplishments

Results showed an increase in power and torque for the variable hardness coating over the baseline coating. A reduction in blowby was also observed. SwRI is working directly with a ring supplier to bring this to market. A patent application was filed 09/20/2023, SWR4189 Variable hardness nanocomposite coating.

Figure 1: Engine torque vs engine speed for baseline and VH6 variable ring coating.

Figure 2: Engine horsepower vs engine speed for baseline and VH6 variable ring coating.