Welcome to the forefront of battery thermal management with battery immersion cooling – a technology poised to transform the performance, safety, and longevity of battery systems. Immersion cooling submerges electric vehicle batteries in a thermally conductive dielectric fluid, dissipating heat more effectively than traditional air-cooling or indirect cooling methods. In the pursuit of optimal thermal management, immersion cooling enables uniform cooling to maximize battery performance and safety. By eliminating temperature differentials within battery packs, immersion cooling minimizes the risk of degradation and ensures consistent operation. Southwest Research Institute offers research and testing of fluids, materials, cells, packs and other battery immersion cooling technology used in electric vehicles and energy storage systems.

For more information, contact Andre Swarts at +1 210 522 6631.

Performance, Safety & Abuse Testing

Pouch cell testing rig.

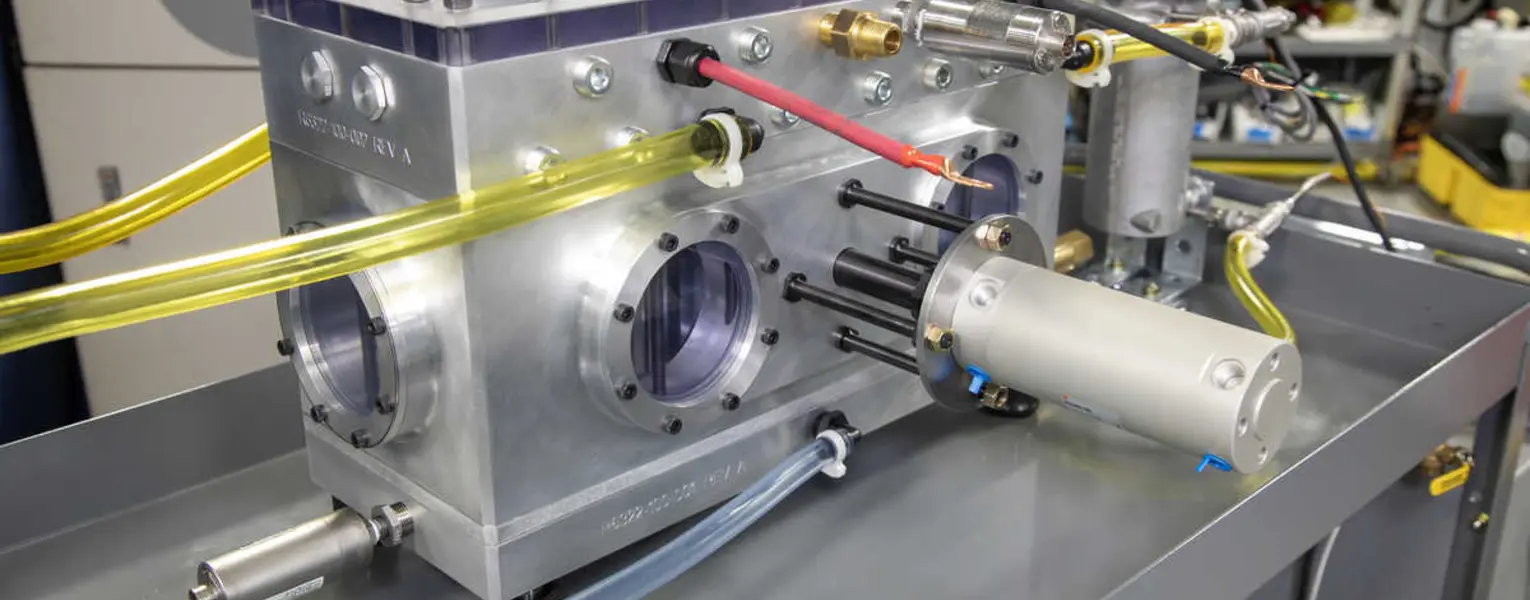

A flow rig for immersion cooling testing.

A fluid combustibility rig.

Performance testing lies at the heart of battery immersion cooling development, ensuring efficacy across diverse applications. Abuse testing confirms that a battery can withstand adverse conditions, including mechanical failures, overcharging, short circuits and external shocks. Testing not only validates its safety features but also instills confidence in real-world deployments, where reliability is paramount.

- Comprehensive test coverage

- Performance testing

- Abuse testing

- Adherence to standards

- Customizations and modification

- Expert guidance and test support

- State-of-the-art facilities

- EV battery immersion cooling solutions

Common Test Articles

SwRI can handle diverse battery configurations, including brick, buck, strings, modules, or entire battery packs, for conducting comprehensive performance and abuse tests. Most battery cell formats, sizes and capacities can be tested with the existing capabilities.

Common Tests for Immersion Coolant

Many available test standards acknowledge the battery immersion cooling practices but do not address it in terms of operating procedures for testing itself. SwRI recommends testing in the spirit of SAE J2464 (August-2021) with minor necessary changes in the procedures.

| Fluid Property Characterization | Dielectric performance, viscosity, heat capacity, etc. |

| Fluid Material Compatibility | Analyzing interactions between the coolant and cell/module/battery pack materials. |

| Fluid Combustibility (with/without Emissions Characterization) | Immersive coolant performance in terms of fluid combustibility and heat transfer will be observed by submerging a heated cell-like metal blank in the fluid suddenly – creating abuse-equivalent conditions without a live cell. |

| Heat Transfer Evaluation | Evaluation of various heat transfer characteristics like heat rejection/dissipation at different mass flow rates, convective heat transfer coefficient against different Reynolds numbers, by circulating the coolant in a heat transfer flow rig. |

| Performance Testing | Article will be cycled on required charge-discharge profile, set fluid temperature and flow rate, for a specific number of cycles or weeks. A reference performance test (RPT) is carried out at regular intervals to analyze the article performance throughout the testing. |

| Abuse Testing (with/without FTIR) | Mechanical (Nail Penetration), thermal (heat induced) or electrical (overcharge/short-circuit) abuse and thermal runaway or passive propagation resistance tests using single cell abuse. |

| Specialized Tests | SwRI has extensive experience in designing and executing specialized tests, including active immersion cooling with dielectric coolant, indirect cooling with water-based coolant and other customized setups tailored to client specifications. |

| Pouch Cell Testing | Traditionally, pouch cells rely on indirect cooling mechanisms. SwRI developed a pressurized enclosure to accommodate multiple pouch cells, evaluating their performance, safety, and thermal management characteristics in a controlled environment. |

| Module & Pack Testing | SwRI provides abuse testing services for battery modules and packs, with the option for integration with immersion cooling technology, which enables clients to assess the resilience and effectiveness of their battery systems in real-world scenarios. |

EVESE-II Consortium offers EV Battery Immersion Cooling R&D

EV battery immersion cooling has been a significant focus of research within SwRI's automotive consortia. Electrified Vehicle & Energy Storage Evaluation-II (EVESE-II) will build upon our established expertise in battery cell research and expand our focus to include module and pack research, with an emphasis on immersion cooling, test standards, safety testing, and applications beyond electric vehicles, such as charging and V2X (Vehicle-to-Everything) systems.

View Experimental and Theoretical Analysis of Immersion Cooling of a Li-Ion Battery Module published research.