Barrier valves play an important role in downhole completion in oil and gas operations. Barrier valves isolate the reservoir and contain fluids during completion and work over operations. Subsea valves and well intervention equipment are used during inervention to extend production of wells by improving performance and/or tapping into additional hydrocarbon reservoirs.

Downhole Completion Barrier Valve Testing

API 19V Subsurface Completion Isolation (Barrier) Valves & Related Equipment

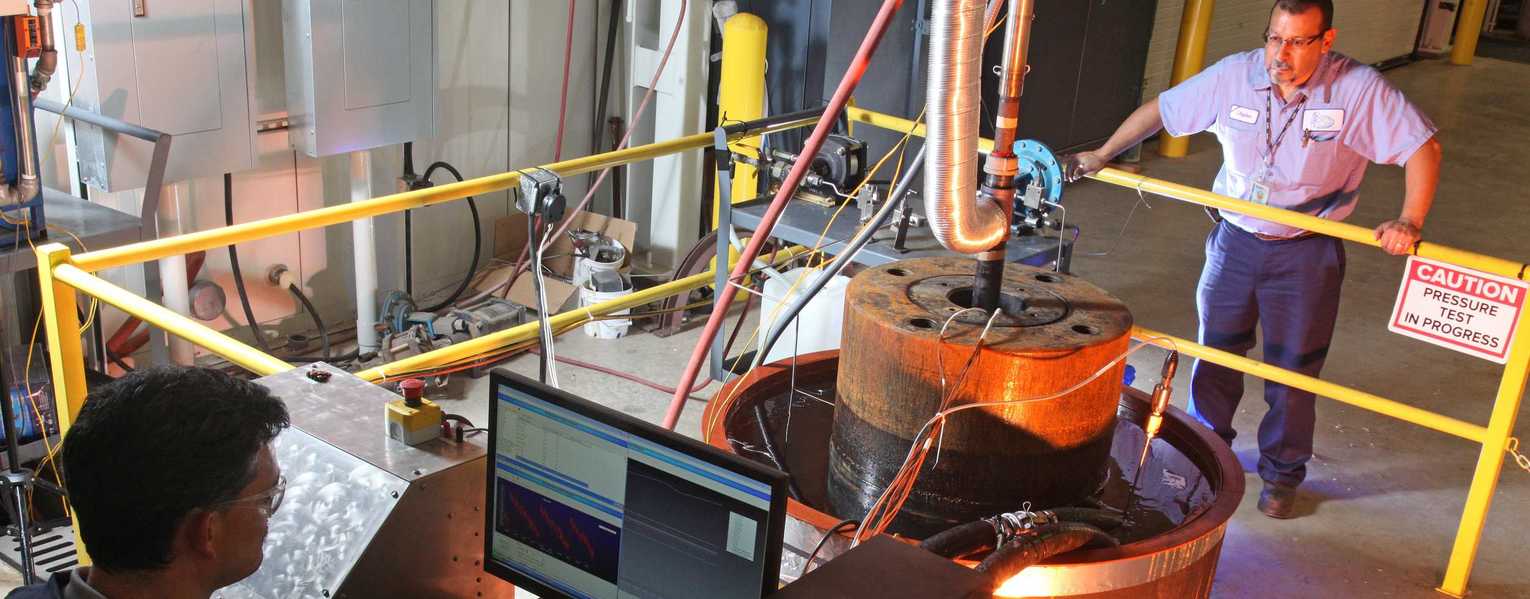

SwRI performs testing of Subsurface Completion Isolation Valves (SCIV) per API 19V, ISO 28781, and per client-specific testing procedures.

- Validation Testing and Slurry Testing of Double Letter Valves – Annex B

- Closure Against Sand Slurry Flow – Annex H

- Debris Settling Design Validation – Annex G

API 17G Design & Manufacture of Subsea Well Intervention Equipment

SwRI performs testing on subsea well intervention equipment, such as lubricator valves, retainer valves, subsea test tree/flowhead valves, and shear rams/cutters.

- Annex G – Validation Testing of Subsea Test Tree Assemblies

- Annex H – Validation Testing of Well Control Devices for Open Water Well Intervention

- Controlled Temperature Testing

- Sand Slurry Testing, Classes I, II, and III

- Dynamic Closure Testing, Liquid and Gas

- Cycle and Pressure Testing

- Pump-Through Kill Test

- Chemical Injection Test

Visit Safety Valve Testing to learn more about SSSV testing.

For more information about downhole completion and subsea valve testing, please contact Christopher Jowers at +1 210 522 4221.