Southwest Research Institute’s long history of performing erosion research and testing has led to the development of new and improved operating procedures and analysis techniques that have expanded our understanding of the characteristics of erosive process flows. SwRI’s Erosion Flow Test Facilities perform performance testing of full-scale test articles and material coupons in an erosive flow environment. Customized flow loops or facility modifications can be designed and implemented utilizing existing equipment to meet specific needs.

Energy Production Erosion Analysis

In addition to hydrocarbons, sand and produced water are often accumulated during the oil and gas production process. Control screens used to trap these impurities eventually erode, which can lead to damage of downstream equipment. SwRI offers a variety of erosion testing, analysis and modeling services, including:

- Sand Control Services

- Sand Control Screen Erosion Evaluation

- Gravel Packing and Plugging Testing

- Downhole Tool Erosion Testing

- Inflow Control Device (ICD) Multiphase Testing

- Full-Scale ICD and Sand Control Screens Erosion Testing (before/after flow performance evaluation)

- Electro Submersible Pump (ESP) Erosion Testing

- Flow Meter Erosion Testing

- Effect of Particle Size/Concentration, Liquid Viscosity, Material Type and Impingement Angle on Erosion Rate

- Determination of Erosion Rate on Various Material Coupons

- Determination of Erosion Rate on Piping ID in Complicated Geometries

- Fitment for Service Testing (Slurry Erosion)

Erosion Flow Test Facilities

SwRI has three erosive flow facilities dedicated to liquid particle flow testing. The facilities can perform flow testing on full-scale test articles or materials to mimic a wide variety of field conditions. The three facilities are designed to perform testing with sand and water, but can operate with fluids such as particle-laden oils, drilling muds, and polymers.

Erosion Evaluation & Analysis

Southwest Research Institute has a wealth of experience, facilities, and equipment that can be leveraged to help our customers with:

- Product design improvements for erosive environments

- Unbiased third party testing of competitive products for performance

- Prediction of maintenance or end of life schedules for equipment in erosive environments

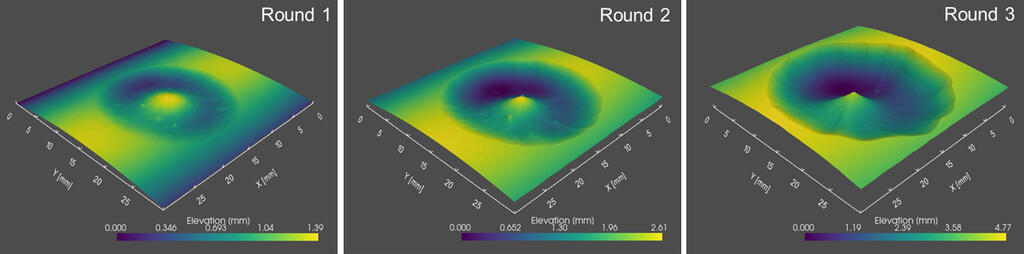

SwRI uses advanced imaging and surface profilometry technology along with computational analysis to determine the location and magnitude of erosion that is imparted on a test article during erosive slurry flows. This technique has been applied to many different types of geometries, such as measuring the wear on the inside of an ell in a process flow application, or measuring the impact of a slurry jet as it impinges on different protective coatings.

The outputs of these imaging technologies can be used for further analysis, i.e., obtaining height profiles or section cuts, or computing volumes of erosive wear.

Erosion evaluation can take place in between slurry flows to determine the erosion rate of a material or test article. A combination of 3D surface scanning and computational analysis can provide both qualitative results that can be compared at a quick glance and quantitative results that reveal the volume, surface area and depth of material removed.

3D surface scanning and computational analysis is used in locations like the inner and outer radius of a piping elbow that is subjected to slurry flows, where very little erosion is expected. A specific erosion rate can be calculated and used to estimate maintenance intervals.

Computational Fluid Dynamics (CFD) Erosion Modeling

In addition to erosion testing, SwRI has developed a CFD erosion model that utilizes the results from CFD simulations to predict material loss. This model has been experimentally validated to be more accurate than other models, even when predicting erosion in relatively complicated geometries. This capability is particularly useful during the design of products, where an understanding of erosion behavior is critical between design iterations and in applications where testing is not feasible. For details on SwRI's erosion model, please refer to paper IPC2016-64064 from the 2016 11th International Pipeline Conference. For more information on CFD analysis, visit Fluids Engineering CFD.

For more information about erosion testing, please contact Jessica Brysch, at +1 210 522 2807.