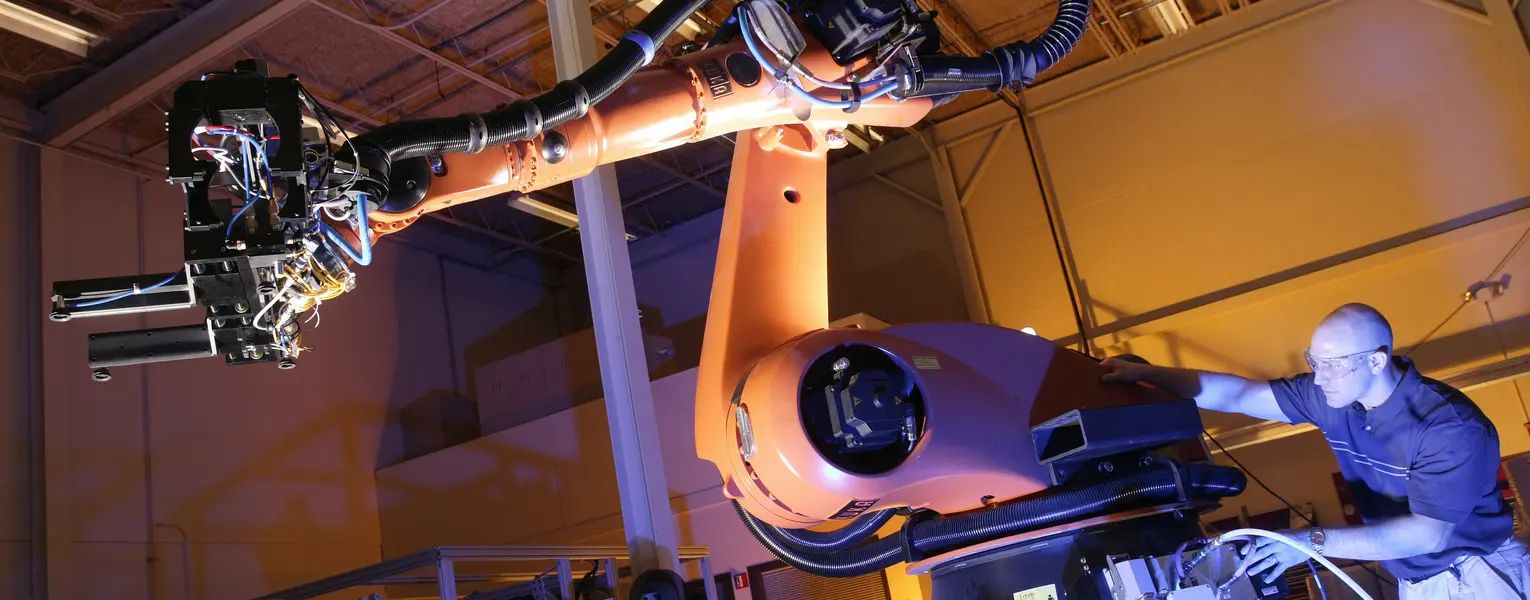

Machine Vision Enables Advanced Automation

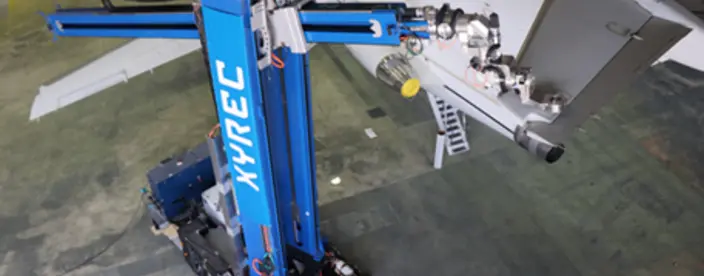

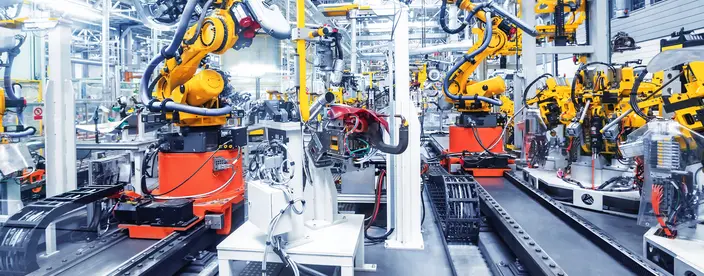

Many manufacturing processes operate using fixed or hard automation equipment that perform production tasks with limited sensory inputs. For more complex applications, simple cameras or sensors can detect an object’s presence, position, size, or thickness. Machine vision solutions can be applied when objects are more complex, less constrained, or their appearance needs to be evaluated. This blog post will review three applications to provide insights into machine vision’s role in advanced automation.