SwRI Cracks Cable Management for Cobots

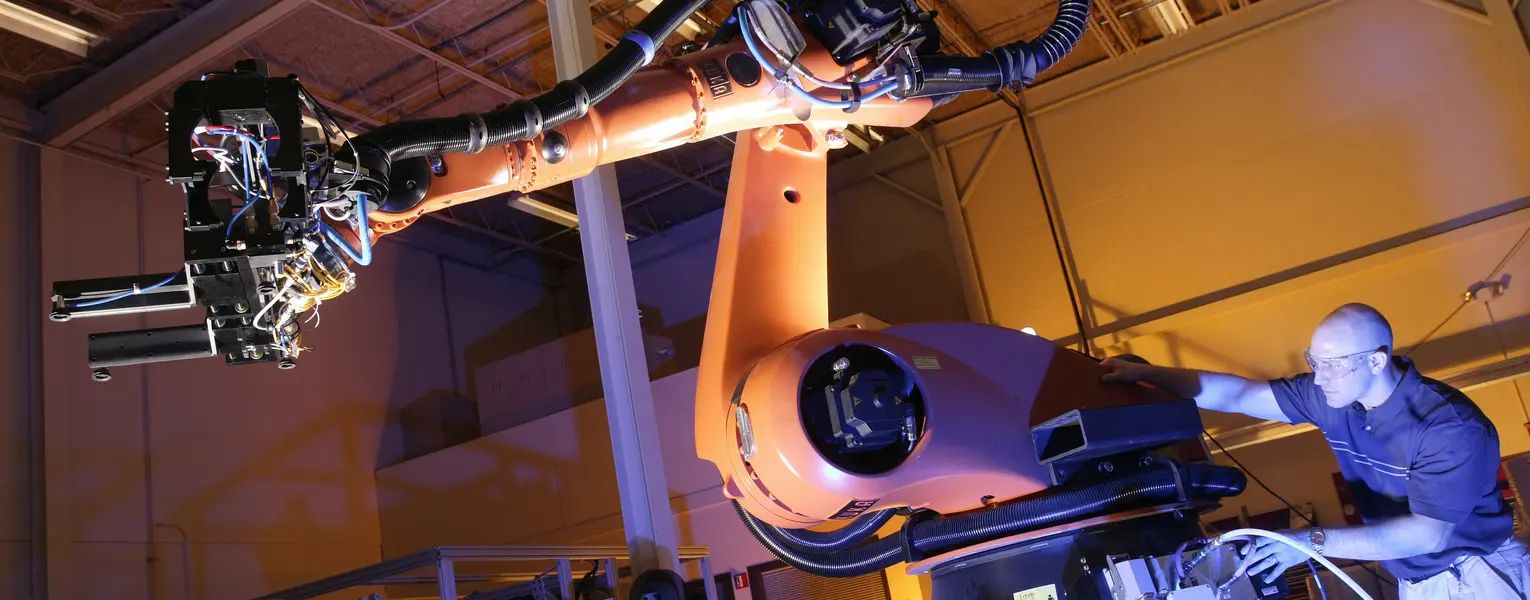

Cable management is the mythical hydra of automation problems. For every edge case that is chopped off and solved, a new one appears to bite you. Dress pack management for collaborative robots, or “cobots,” has been a recurring problem for several years. The dress pack is the bundle of cables and hoses that connect to the robot’s tool flange. The more the robot moves, the more slack is needed to avoid pulling the dress pack so tightly that it gets damaged or stops the robot. If this extra length is left loose, it risks getting tangled.